How To Balance A Rotating Assembly

Balancing a rotating assembly, such as in an engine, is the process of ensuring that the mass is evenly distributed around the axis of rotation. This minimizes vibration and stress, leading to smoother operation, increased engine life, and improved performance. Essentially, it involves identifying and correcting any imbalances that exist within the components that spin together.

Why Balancing a Rotating Assembly Matters

The importance of balancing a rotating assembly cannot be overstated, especially in high-performance or long-lasting applications. Here's why it's crucial:

- Reduced Vibration: An unbalanced assembly creates vibrations that can be felt throughout the vehicle. These vibrations are not only annoying but can also cause fatigue and damage to other engine components, chassis, and even the driver!

- Increased Engine Life: Excessive vibration puts undue stress on bearings, crankshafts, connecting rods, and other vital engine parts. Over time, this stress leads to premature wear and tear, shortening the engine's lifespan. Balancing significantly reduces this stress, leading to a longer-lasting and more reliable engine.

- Improved Performance: An unbalanced assembly robs the engine of power. Some of the engine's energy is wasted in creating and combating the vibrations instead of being used to turn the wheels. Balancing allows the engine to operate more efficiently, resulting in increased horsepower and torque.

- Smoother Operation: A balanced engine runs much smoother, making for a more pleasant driving experience. The reduced vibration translates into less noise and a more comfortable ride.

- Preventing Catastrophic Failure: In extreme cases, severe imbalance can lead to catastrophic engine failure. The excessive stress can cause components to break apart, resulting in significant damage and potentially dangerous situations.

Imagine a washing machine with clothes all bunched up on one side. The machine vibrates violently because the weight is unevenly distributed. The same principle applies to an engine. Balancing is like distributing the clothes evenly, so the washing machine runs smoothly and efficiently.

How to Choose the Right Balancing Method and Service

When it comes to balancing a rotating assembly, several methods and services are available. Selecting the right one depends on your engine's specific needs, performance goals, and budget. Here's a breakdown of factors to consider:

Types of Balancing

- Static Balancing: This is the simplest form of balancing, performed with the assembly at rest. It identifies the heaviest point on the assembly, allowing for weight to be added or removed to achieve balance. Static balancing is suitable for low-speed applications where precision isn't critical.

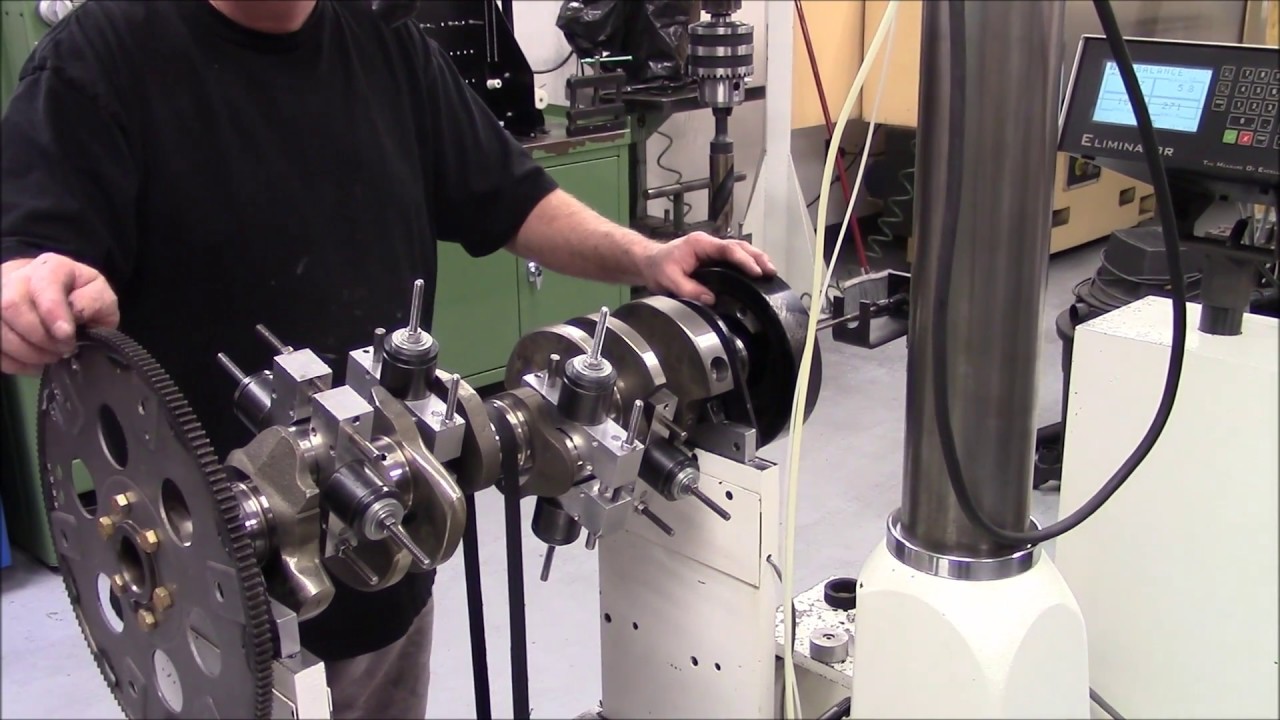

- Dynamic Balancing: This method is more sophisticated and accurate than static balancing. It involves spinning the assembly at high speeds while sensors measure the vibrations caused by imbalances. This allows for the precise identification and correction of imbalances in multiple planes. Dynamic balancing is essential for high-performance engines and those operating at higher RPMs.

- Individual Component Balancing: Before the rotating assembly is put together, each component (crankshaft, connecting rods, pistons, etc.) can be individually balanced. This often involves weighing each part and removing small amounts of material to ensure they are all within a very tight weight tolerance.

- Harmonic Balancing: Specifically refers to the harmonic balancer (also called a vibration damper) which is designed to absorb torsional vibrations in the crankshaft. While not balancing the entire rotating assembly, a properly functioning harmonic balancer is crucial for engine longevity.

Factors to Consider When Choosing a Balancing Service

- Experience and Expertise: Choose a shop with a proven track record of balancing rotating assemblies. Look for certifications and experience with your specific engine type. Read online reviews and ask for references.

- Equipment: The balancing shop should have state-of-the-art equipment, including dynamic balancing machines and precision scales. The quality of the equipment directly affects the accuracy of the balancing process.

- Precision and Tolerances: Discuss the acceptable tolerances with the shop. For high-performance engines, tighter tolerances are crucial. Ask for a detailed report outlining the balancing process and the final results.

- Cost: Balancing costs can vary significantly depending on the complexity of the job and the expertise of the shop. Get quotes from multiple shops and compare their services and prices. Remember that the cheapest option isn't always the best; quality and accuracy are paramount.

- Turnaround Time: Inquire about the estimated turnaround time. Balancing can take several days or even weeks, depending on the workload of the shop.

- Reputation: Check online forums, talk to other enthusiasts, and research the shop's reputation. A good reputation is a sign of quality work and customer satisfaction.

Questions to Ask Potential Balancing Services

- What type of balancing do you recommend for my engine and application?

- What are your tolerances for imbalance?

- What equipment do you use?

- Can I see examples of your work?

- What is the turnaround time?

- What is the cost?

- Do you offer any warranty on your work?

Real-World Owner Experiences

Many car enthusiasts and mechanics attest to the significant benefits of balancing a rotating assembly. Here are some real-world experiences:

- Classic Car Restorations: Owners restoring classic cars often find that balancing the rotating assembly significantly improves the smoothness and reliability of their engines. One restorer shared, "After balancing the rotating assembly on my vintage Mustang, the engine runs smoother than it ever did. The vibrations are gone, and it feels like a completely different car."

- High-Performance Builds: Performance enthusiasts building high-horsepower engines rely on balancing to ensure durability and maximize power output. A drag racer stated, "Balancing is essential for any serious engine build. It prevents premature wear and tear on the components and allows the engine to rev higher and produce more power safely."

- Daily Drivers: Even in everyday vehicles, balancing can make a noticeable difference. One driver reported, "I had my engine balanced after noticing excessive vibration. The difference is night and day. The engine runs smoother, and I'm sure it will last longer."

These experiences highlight that balancing a rotating assembly is a worthwhile investment for any engine, regardless of its intended use. The benefits extend beyond performance to include longevity and overall driving enjoyment.

Frequently Asked Questions (FAQs)

Q: How often should I balance my rotating assembly?

A: Generally, you only need to balance your rotating assembly when rebuilding or modifying your engine. If you're experiencing unusual vibrations or suspect an imbalance, it's worth having it checked.

Q: Can I balance a rotating assembly myself?

A: While technically possible, balancing requires specialized equipment and expertise. It's best left to professionals with the right tools and knowledge.

Q: What are the symptoms of an unbalanced rotating assembly?

A: Common symptoms include excessive engine vibration, unusual noises, premature bearing wear, and reduced engine performance.

Q: How much does it cost to balance a rotating assembly?

A: The cost can vary depending on the complexity of the job and the shop you choose. Expect to pay anywhere from $300 to $1000 or more.

Q: What is a bob weight?

A: Bob weights are used during crankshaft balancing to simulate the weight of the connecting rods, pistons, and piston pins. They are attached to the connecting rod journals on the crankshaft to accurately represent the dynamic forces acting on the crankshaft during operation.

Q: Is balancing necessary for a stock engine rebuild?

A: While not always mandatory, balancing is highly recommended even for stock engine rebuilds. It ensures smoother operation and extends the life of the engine.

Q: Can balancing improve fuel economy?

A: While not a direct improvement, a balanced engine operates more efficiently, which can contribute to slightly improved fuel economy.

By understanding the importance of balancing and choosing the right service, you can ensure your engine runs smoothly, efficiently, and reliably for years to come. Don't underestimate the power of a properly balanced rotating assembly!