How To Build A Cross Out Of 4x4

So, you're looking to build a sturdy cross out of 4x4 lumber? Excellent! Whether you're tackling a DIY project, need a robust support structure, or just want a fun weekend build, understanding the principles behind constructing a strong cross joint is crucial. This article will break down the process, covering everything from material selection to assembly techniques, ensuring you create a cross that's both structurally sound and visually appealing. We'll delve into the key specifications, explain how the joint works, and offer real-world troubleshooting tips. Plus, we have a detailed diagram available for download to guide you every step of the way. Let's get started!

Purpose and Importance

Why bother with meticulously planning and executing this cross joint? Well, consider the applications. A well-built 4x4 cross can serve as the foundation for a garden pergola, a sturdy support for a heavy object, a decorative element in your landscaping, or even a component in furniture construction. Understanding the principles of load distribution and joint integrity is paramount. A poorly constructed cross can lead to structural failure, resulting in damage or even injury. This guide, along with the downloadable diagram, provides the knowledge and blueprint needed to avoid these pitfalls and create a strong, durable cross.

Key Specs and Main Parts

Let's break down the core elements involved:

- 4x4 Lumber: When we say "4x4," we're referring to the nominal dimensions. In reality, a 4x4 piece of lumber typically measures 3.5 inches by 3.5 inches. Species matters! Pressure-treated lumber is ideal for outdoor projects as it resists rot and insect infestation. Cedar and redwood are naturally resistant but more expensive. Pine is a more budget-friendly option but requires sealing and regular maintenance if exposed to the elements.

- The Cross Joint: This is the heart of the structure. The type of joint significantly impacts strength. We will focus on a half-lap joint for this guide, which provides a good balance of strength and ease of construction.

- Fasteners: Screws or bolts are used to secure the joint. Exterior-grade screws are essential for outdoor use to prevent rust. The length should be sufficient to penetrate deep into both pieces of lumber but not so long as to protrude completely through the other side. For a truly robust joint, consider using carriage bolts with washers and nuts.

- Adhesive (Optional): A weather-resistant wood glue, such as polyurethane glue, can significantly strengthen the joint and prevent water intrusion.

- Protective Finish: Sealant, stain, or paint to protect the wood from the elements and enhance its appearance.

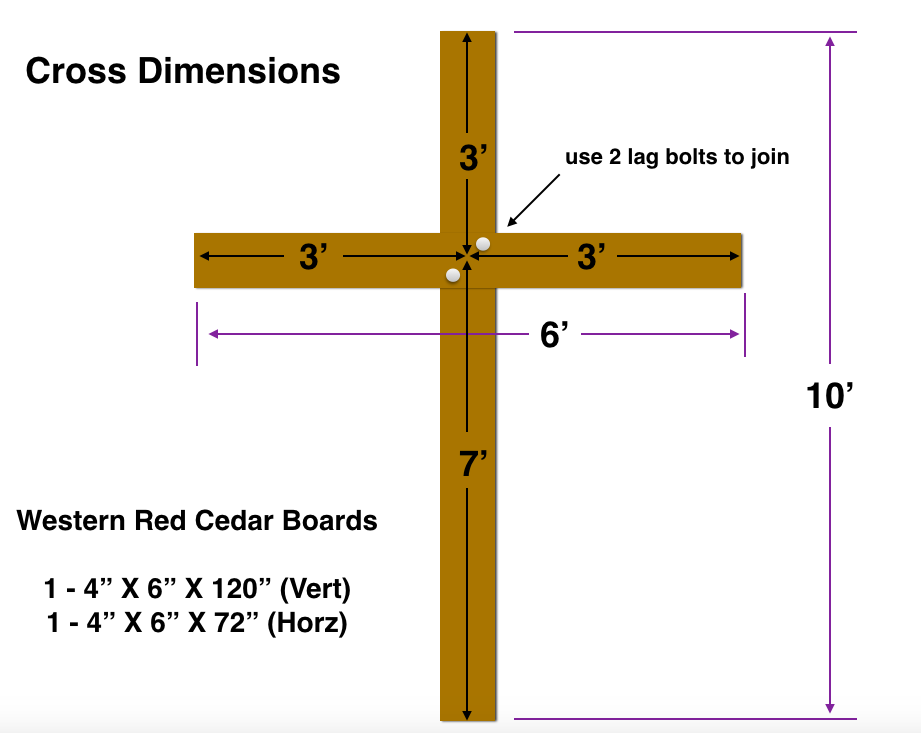

Understanding the Diagram

The downloadable diagram is your visual guide. Here's a breakdown of common elements you'll encounter:

- Solid Lines: Represent visible edges of the lumber.

- Dashed Lines: Indicate hidden edges or parts that are obscured in a particular view. In our diagram, these are often used to show the extent of the half-lap cut.

- Dimensions: Numerical values with units (inches or millimeters) that specify the length, width, and depth of various components. Pay close attention to these! Accuracy is key for a successful joint.

- Arrows: Indicate the direction of measurements or forces.

- Hatching or Shading: May be used to differentiate between different parts or materials. In the case of half-lap, this visually highlights material that is to be removed.

- Symbols for Fasteners: Typically, a circle represents the head of a screw or bolt. A line might indicate the shank of the fastener.

- Color Coding (if applicable): Different colors may be used to highlight specific features or components. For example, one color might represent the area where glue should be applied.

How It Works: The Half-Lap Cross Joint

The half-lap joint works by removing half the thickness of each piece of lumber where they intersect. This creates two mating surfaces that sit flush with each other, distributing the load evenly across the joint. Here's the process:

- Precise Measurements: Accurate measurements are paramount. For a 4x4, you'll need to remove approximately 1.75 inches (half the actual thickness of 3.5 inches) from each piece of lumber. Mark the areas to be removed clearly.

- Cutting the Laps: This can be done with a circular saw, a hand saw, or a router. If using a circular saw, make multiple passes to remove the material gradually. If using a router, employ a jig to ensure a consistent depth of cut. A sharp chisel is crucial for cleaning up the corners and ensuring a tight fit.

- Test Fit: Before applying any glue or fasteners, dry-fit the joint to ensure the two pieces fit snugly together. If there are gaps, use a chisel or sandpaper to refine the fit.

- Adhesive Application (Optional): Apply a generous amount of weather-resistant wood glue to the mating surfaces.

- Fastening: Use exterior-grade screws or carriage bolts to secure the joint. Pre-drilling pilot holes is recommended to prevent the wood from splitting, especially when using screws near the ends of the lumber. If using bolts, ensure the holes are accurately aligned.

- Clamping: Clamp the joint tightly while the glue dries. This ensures a strong bond and prevents movement.

- Finishing: Once the glue is dry, sand the joint smooth and apply a protective finish to seal the wood.

Real-World Use: Basic Troubleshooting

Even with careful planning, issues can arise. Here are some common problems and their solutions:

- Gaps in the Joint: This indicates inaccurate cuts. Use wood filler to fill small gaps, but if the gaps are significant, consider recutting the joint.

- Splitting Wood: This is usually caused by driving screws or bolts without pre-drilling pilot holes. Use pilot holes to prevent splitting.

- Weak Joint: A weak joint can be caused by several factors: insufficient glue, inadequate fasteners, or inaccurate cuts. Ensure the joint is properly assembled and secured.

- Water Intrusion: Protect the joint from moisture by applying a weather-resistant finish and sealing any gaps.

If the joint fails under load, it’s likely that the lumber wasn't adequately sized for the application. Consider using larger lumber or reinforcing the joint with metal brackets.

Safety Considerations

Working with power tools and lumber can be dangerous. Always prioritize safety:

- Eye Protection: Wear safety glasses or goggles to protect your eyes from flying debris.

- Hearing Protection: Use earplugs or earmuffs when operating noisy power tools like circular saws or routers.

- Dust Mask or Respirator: Wear a dust mask or respirator to prevent inhaling sawdust.

- Gloves: Wear gloves to protect your hands from splinters and sharp edges.

- Secure Workpiece: Ensure the lumber is securely clamped or held in place before cutting or drilling.

- Tool Maintenance: Keep your tools sharp and in good working order. Dull blades are more likely to cause kickback.

- Be aware of electrical hazards. When using power tools, ensure the power cord is in good condition and avoid working in wet conditions.

Remember, power tools are dangerous if used incorrectly. Read and understand the manufacturer's instructions before operating any power tool.

Download the Diagram

We've covered a lot of ground here, but the best way to truly understand this project is by visualizing it. A detailed diagram will provide a clear roadmap for your build. We have a downloadable file available with precise measurements and visual aids to guide you through the process. With this diagram and the knowledge you've gained here, you'll be well-equipped to build a strong and aesthetically pleasing cross out of 4x4 lumber. Good luck with your project!