How To Build An Electric Car

Building Your Own Electric Car: A Deep Dive

So, you're thinking about electrifying your ride? Fantastic! Converting a car to electric power is a challenging but incredibly rewarding project. This article serves as your detailed guide, walking you through the core components, their functions, and the critical considerations involved in building your own electric vehicle (EV). Think of this as a comprehensive blueprint – we're not just glossing over the basics; we're diving deep into the mechanics and electronics.

Purpose: This guide isn't about providing a simple "plug-and-play" solution. It's about understanding the fundamental principles behind EV conversions. Knowing these principles empowers you to diagnose issues, customize your build, and truly understand the technology driving your electric vehicle. Whether you're planning a complete conversion, modifying an existing EV, or just expanding your knowledge, this information is invaluable.

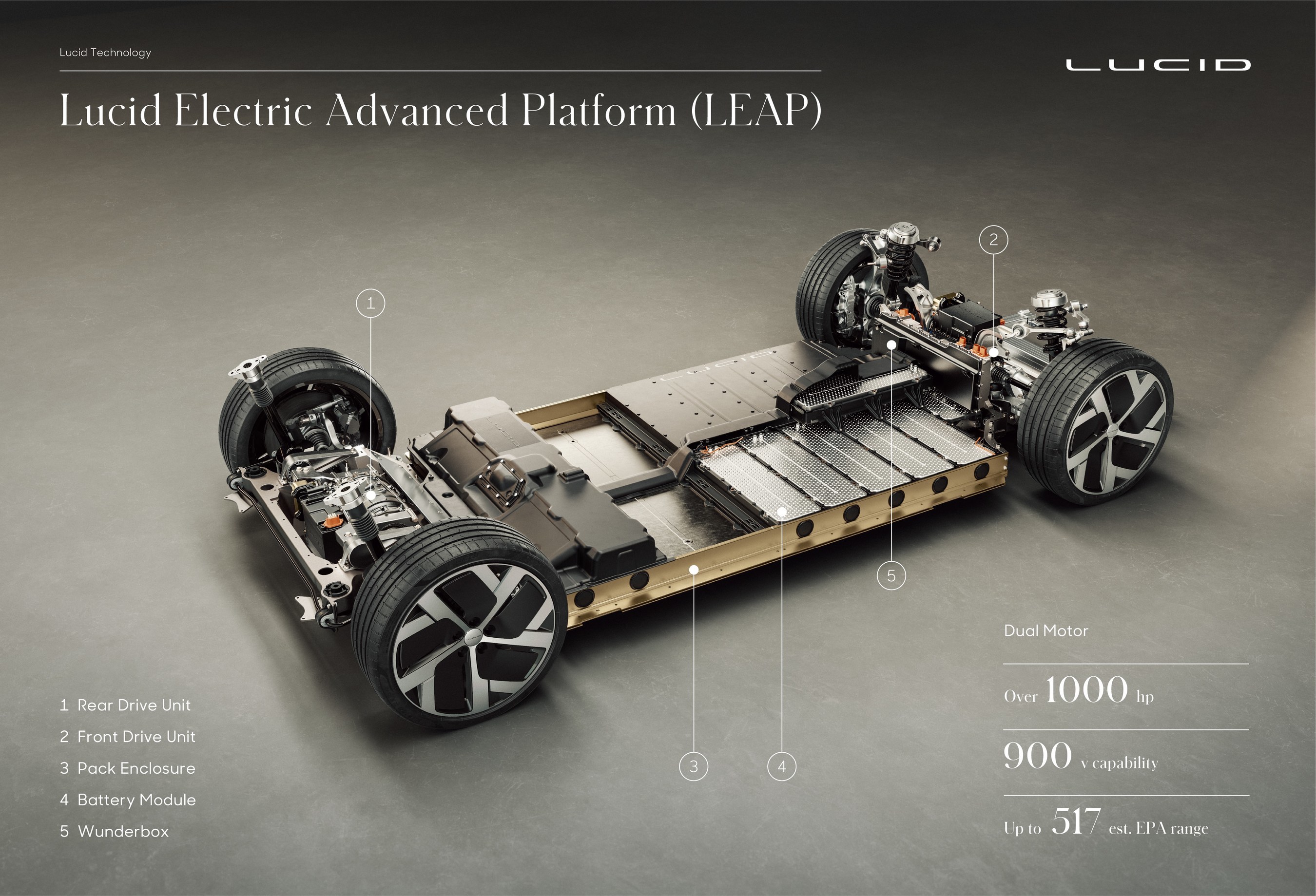

Key Specs and Main Parts

The heart of any EV conversion lies in its core components. Let's break down the key players:

- Battery Pack: The energy reservoir. Typically, these are lithium-ion batteries (Li-ion) due to their high energy density and relatively long lifespan. Key specs include:

- Voltage (V): Determines the system voltage. Higher voltage allows for smaller currents, reducing losses.

- Capacity (Ah - Ampere-hours): Indicates how much charge the battery can store, affecting range.

- Energy (kWh - Kilowatt-hours): Combines voltage and capacity to represent the total stored energy.

- C-Rate: Measures how quickly the battery can be charged or discharged. A higher C-rate means faster charging/discharging.

- Electric Motor: The powerplant that converts electrical energy into mechanical energy to drive the wheels. Common types include:

- AC Induction Motors: Robust and relatively simple, often used in mass-produced EVs.

- Permanent Magnet Synchronous Motors (PMSM): More efficient and powerful, often found in performance EVs.

- Power (kW/HP): Determines the motor's output and the vehicle's acceleration.

- Torque (Nm/lb-ft): Measures the rotational force the motor can produce, impacting initial acceleration and climbing ability.

- RPM (Revolutions Per Minute): The maximum rotational speed of the motor.

- Motor Controller: The brain that regulates the flow of energy from the battery to the motor. It controls the motor's speed, torque, and direction. Key specs include:

- Voltage Rating: Must match the battery pack voltage.

- Current Rating: Indicates the maximum current the controller can handle without overheating.

- Control Strategy: Determines how the controller manages the motor (e.g., Field-Oriented Control - FOC).

- Battery Management System (BMS): The guardian of the battery pack. It monitors individual cell voltages, temperature, and current, protecting the battery from overcharging, over-discharging, and overheating.

- Cell Balancing: Ensures all cells in the pack have equal charge levels.

- Thermal Management: Monitors and controls battery temperature for optimal performance and lifespan.

- DC-DC Converter: Steps down the high voltage from the battery pack to a lower voltage (typically 12V) to power the car's auxiliary systems (lights, wipers, etc.).

- Onboard Charger (OBC): Converts AC power from a wall outlet into DC power to charge the battery pack.

- Wiring and Connectors: High-voltage wiring is crucial for safely and efficiently transmitting power between components. Proper connectors are essential to prevent arcing and ensure reliable connections.

- Cooling System: Many EV components, especially the motor and controller, generate significant heat. A cooling system (liquid or air-cooled) is necessary to prevent overheating and damage.

How It Works

The process is deceptively simple at a high level:

- The driver presses the accelerator pedal.

- The accelerator pedal position is interpreted by the motor controller.

- The motor controller requests power from the battery pack.

- The BMS monitors the battery's health and allows the flow of current.

- The motor controller regulates the flow of energy to the electric motor.

- The electric motor converts electrical energy into mechanical energy, turning the wheels.

- Regenerative braking allows the motor to act as a generator during deceleration, recovering energy and sending it back to the battery pack.

Delving Deeper: The motor controller utilizes sophisticated algorithms (often Field-Oriented Control) to precisely manage the motor's torque and speed. FOC allows for efficient and responsive control by independently controlling the motor's torque-producing and flux-producing currents.

Real-World Use – Basic Troubleshooting Tips

Even with a meticulously planned build, issues can arise. Here are a few common problems and troubleshooting steps:

- Reduced Range:

- Check battery health using the BMS interface. Look for unbalanced cells or cells with significantly lower capacity.

- Inspect tire pressure. Underinflated tires increase rolling resistance.

- Evaluate driving habits. Aggressive acceleration and high speeds consume more energy.

- Verify the BMS isn't limiting current due to temperature issues.

- Motor Not Responding:

- Check all wiring connections, especially high-voltage connectors. Look for loose connections or corrosion.

- Verify the motor controller is receiving power and sending signals to the motor. Use a multimeter to check voltage and continuity.

- Inspect the motor for any signs of damage or overheating.

- Check the accelerator pedal position sensor (APPS) output.

- Charging Problems:

- Ensure the charger is properly connected to the vehicle and the power outlet.

- Check the charger's display for error codes. Consult the charger's manual for troubleshooting.

- Verify the BMS is allowing charging.

- Inspect the charging port and wiring for damage.

- BMS Errors: Consult the BMS documentation to decipher the error code. BMS errors are often related to cell imbalances, over-voltage, under-voltage, or over-temperature conditions. Addressing BMS errors often requires specialized tools and knowledge.

Safety – Handling High Voltage

WARNING: Working with high-voltage systems is extremely dangerous and can be fatal. Always take the following precautions:

- Disconnect the battery pack before working on any electrical components.

- Use insulated tools specifically designed for high-voltage applications.

- Wear appropriate personal protective equipment (PPE), including insulated gloves and eye protection.

- Never work alone. Have someone present who can provide assistance in case of an emergency.

- Discharge capacitors before handling them. Capacitors can store a dangerous amount of energy even after the power is disconnected.

- Understand the specific safety procedures for your chosen battery pack, motor controller, and other high-voltage components.

High-voltage components like the battery pack, motor controller, and DC-DC converter are particularly hazardous. Even after the power is disconnected, these components can retain a significant charge. Follow all safety procedures carefully and consult with a qualified electrician if you are unsure about any aspect of the electrical system.

Symbols and Lines

Understanding the diagrams of electrical components is essential. Here are a few common things to remember:

- Solid Lines: Typically represent conductive wires.

- Dotted Lines: Often indicate control signals or communication buses (e.g., CAN bus).

- Colors: While not standardized, red often represents positive voltage, black represents ground or negative voltage, and other colors indicate specific signal functions.

- Component Symbols: Resistors (zigzag line), capacitors (two parallel lines), inductors (coiled line), diodes (triangle pointing to a line), transistors (various configurations), and so on.

Reading datasheets of each component is crucial in understanding symbols and safety specifications.

Converting a car to electric power is a complex undertaking, but with careful planning, meticulous execution, and a thorough understanding of the underlying principles, you can successfully build your own electric vehicle. Remember to prioritize safety and consult with experienced professionals when needed. With the right knowledge and resources, you can join the growing community of EV enthusiasts and contribute to a cleaner and more sustainable future.