How To Build And Electric Car

So, you want to build an electric car? That's an ambitious project, but definitely achievable with the right knowledge and dedication. This article will break down the key components and considerations involved in converting a gasoline-powered vehicle to electric power or building an EV from the ground up. We'll focus on the practical aspects, assuming you have some existing mechanical and electrical skills.

Purpose and Scope

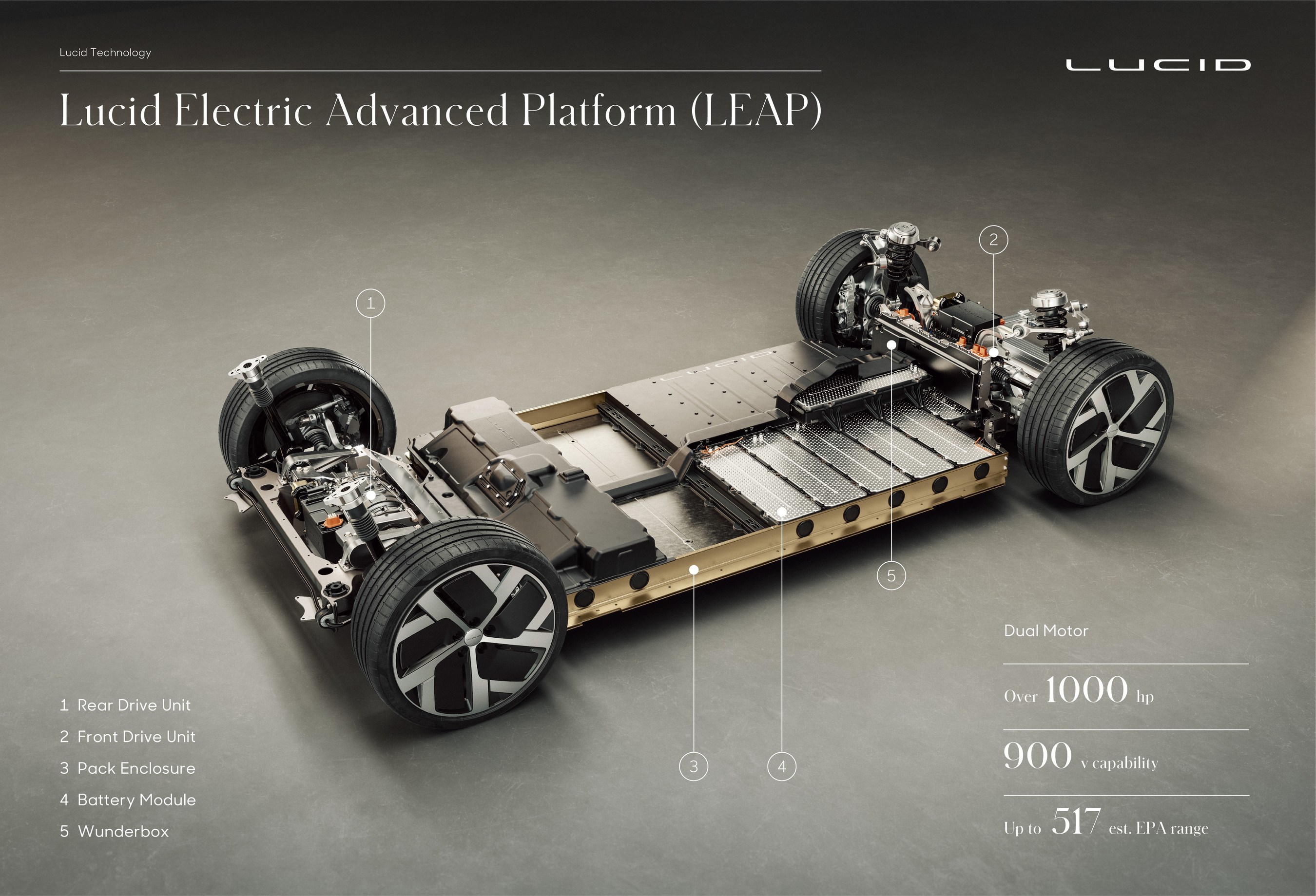

Understanding the diagram of an EV's electrical system is crucial for several reasons. Primarily, it helps with diagnostics and repairs. When something goes wrong, tracing the circuits helps pinpoint the fault. It's also invaluable for understanding the overall system architecture, which is essential if you plan on modifying or upgrading your EV in the future. Moreover, gaining this knowledge will empower you to build your own EV from scratch and potentially even design and innovate in the electric vehicle space.

Key Specs and Main Parts

Let's dive into the core components that make an electric car tick:

- Battery Pack: This is the energy reservoir of your EV. It consists of multiple battery modules connected in series and parallel to achieve the desired voltage and capacity. Key specs include voltage (V), capacity (Ah - Ampere-hours), and energy (kWh - Kilowatt-hours). Battery chemistries vary, with lithium-ion being the most common due to its high energy density. A Battery Management System (BMS) is absolutely essential here for the safety of the battery pack, and longevity of individual cells.

- Electric Motor: The heart of the EV, converting electrical energy into mechanical motion. There are several types, including AC induction motors, permanent magnet synchronous motors (PMSM), and switched reluctance motors. The motor's power (kW) and torque (Nm) are key performance indicators.

- Inverter: The inverter converts DC (Direct Current) power from the battery pack into AC (Alternating Current) power required by the electric motor. It's a sophisticated piece of electronics that also controls the motor's speed and torque. It contains many Insulated-Gate Bipolar Transistors (IGBTs) which are the switching transistors.

- Charger: The charger takes AC power from the grid and converts it to DC power to recharge the battery pack. Onboard chargers are integrated into the vehicle, while offboard chargers (charging stations) provide faster charging rates. Chargers are rated in power (kW) and determine how fast you can replenish your battery.

- Battery Management System (BMS): The BMS monitors and controls the battery pack, ensuring its safe and efficient operation. It monitors voltage, current, temperature, and state of charge (SOC), and protects the battery from overcharging, over-discharging, and thermal runaway.

- DC-DC Converter: This converts the high-voltage DC from the battery pack to lower voltages (typically 12V) to power auxiliary systems like lights, wipers, and the infotainment system.

- Transmission (Optional): Some EVs use a single-speed transmission or a reduction gear to optimize the motor's torque output. Others directly drive the wheels.

- Cooling System: Electric car components, especially the battery pack, inverter, and motor, generate a significant amount of heat. A cooling system, typically liquid-based, is required to maintain optimal operating temperatures.

Symbols and Diagram Interpretation

Understanding electrical diagrams is vital. Here's a brief overview of common symbols:

- Solid Lines: Indicate electrical wires. The thickness might indicate the wire gauge (current-carrying capacity).

- Dashed Lines: Often represent communication buses (e.g., CAN bus) for data transfer between different components.

- Resistors: Represented by a zigzag line.

- Capacitors: Two parallel lines.

- Inductors: A coil or series of loops.

- Diodes: A triangle pointing to a line.

- Ground: Usually represented by three horizontal lines decreasing in size, or a triangle pointing downwards.

- Fuses/Circuit Breakers: Protect circuits from overcurrent.

- Motors: Represented by a circle with the letter "M" inside.

- Batteries: Series of long and short parallel lines, indicating multiple cells.

Colors are also frequently used. Red is often positive, black is negative (ground), and other colors indicate different signals or functions.

How It Works

The basic principle is straightforward: The battery pack stores energy. When you press the accelerator pedal, the motor controller (inverter) draws power from the battery and sends it to the electric motor. The inverter manipulates the AC frequency and voltage to control the motor's speed and torque. The motor then spins the wheels, propelling the vehicle.

Regenerative braking captures energy during deceleration. When you lift off the accelerator or apply the brakes, the motor acts as a generator, converting kinetic energy back into electrical energy and storing it in the battery. This increases the vehicle's range.

The BMS is constantly monitoring the battery's health and performance, ensuring that it operates within safe limits. It communicates with the motor controller, charger, and other systems to optimize energy usage and prevent damage to the battery.

Real-World Use – Basic Troubleshooting

Let's look at some common issues and how to approach them:

- Car Won't Start: Check the battery pack voltage with a multimeter. If it's below the minimum operating voltage, the BMS might be preventing the system from starting. Also, check all the safety interlocks (e.g., emergency stop button) and fuses.

- Reduced Range: This could be due to various factors, including battery degradation, tire pressure, driving style, and environmental conditions. Check the BMS data for cell imbalances or other anomalies.

- Charging Issues: If the car won't charge, check the charger's power supply and the charging cable. If you're using a public charging station, try a different one. The onboard charger may have a fault and may need diagnosis.

- Motor Overheating: Ensure that the cooling system is functioning correctly. Check the coolant level and the operation of the coolant pump.

Diagnostic Trouble Codes (DTCs): Most modern EVs have an onboard diagnostic system that stores DTCs when a fault occurs. You'll need an OBD-II scanner (some are specifically designed for EVs) to read these codes and interpret them. Once you have the code, you can research its meaning and troubleshoot the underlying issue.

Safety Considerations

High Voltage is Lethal! The battery pack operates at hundreds of volts DC. Never work on the high-voltage system without proper training and personal protective equipment (PPE), including insulated gloves and a face shield. Always disconnect the battery pack and verify that it's discharged before working on any electrical components.

Battery Safety: Lithium-ion batteries can be dangerous if mishandled. Avoid puncturing, crushing, or exposing them to extreme temperatures. If a battery is damaged or shows signs of swelling or leaking, handle it with extreme caution and dispose of it properly. BMS is there to protect, but it is not infallible.

Capacitors: Inverters and chargers contain large capacitors that can store a significant amount of energy even after the system is disconnected. Discharge these capacitors before working on the circuitry.

Closing Thoughts

Building or converting an electric car is a complex undertaking, but it's also incredibly rewarding. With careful planning, a solid understanding of the underlying technology, and a commitment to safety, you can create a vehicle that's both environmentally friendly and fun to drive. Remember to consult with experienced EV builders and follow all applicable safety regulations.

We have a detailed electrical diagram available for download, providing a more in-depth look at a typical EV system. Contact us for the file.