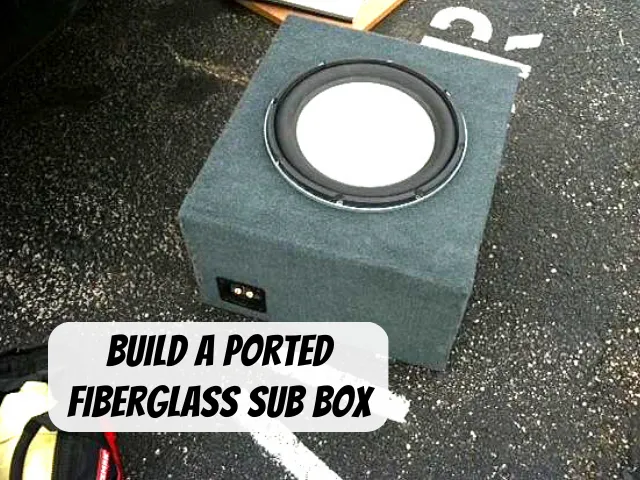

How To Build Fiberglass Sub Box

Building a fiberglass sub box is a rewarding project for any car audio enthusiast looking to maximize their sound system's potential. It allows you to create a custom enclosure tailored to your specific vehicle and subwoofer, often resulting in superior sound quality and a professional, integrated look. This article will guide you through the process, providing a comprehensive overview of how to build a fiberglass sub box, from choosing the right materials to finishing the final product.

Why Building a Fiberglass Sub Box Matters

While pre-fabricated sub boxes are readily available, building a fiberglass enclosure offers significant advantages:

- Custom Fit: Fiberglass allows you to create a box that perfectly contours to your vehicle's interior, utilizing otherwise wasted space. This is especially useful in cars with limited trunk space or unique interior designs.

- Improved Acoustics: By shaping the enclosure optimally, you can potentially enhance the subwoofer's performance, leading to deeper bass and improved sound quality.

- Increased Rigidity: Fiberglass is incredibly strong and rigid when properly layered, minimizing unwanted vibrations and resonance that can muddy the sound. A stiffer enclosure translates to tighter, more accurate bass.

- Aesthetic Appeal: A custom-built fiberglass box can be seamlessly integrated into your vehicle's interior, creating a clean and professional look. You can match the box's finish to your car's interior for a truly custom appearance.

- Cost-Effectiveness (Potentially): While the initial investment in materials might seem high, building your own box can be more cost-effective than purchasing a high-end, custom-made enclosure.

How to Choose the Right Materials and Tools

The success of your fiberglass sub box project hinges on selecting the right materials and tools. Here's a breakdown of the essentials:

Fiberglass Resin and Hardener

This is the primary component of your enclosure. Opt for a high-quality polyester or epoxy resin specifically designed for fiberglass work. Epoxy resin is generally stronger and more resistant to moisture, but it's also more expensive and requires more precise mixing ratios. Polyester resin is more common and easier to work with for beginners. The hardener is crucial for initiating the curing process. Be sure to follow the manufacturer's instructions carefully regarding mixing ratios.

Fiberglass Cloth or Mat

Fiberglass cloth is woven, while fiberglass mat consists of randomly oriented fibers. Fiberglass mat is generally easier to work with, especially on complex shapes, and is often preferred for initial layers. Fiberglass cloth offers greater strength and is suitable for subsequent layers. Choose a weight appropriate for your project; heavier weights offer greater strength but are more difficult to work with.

Mold Release Agent

This is essential for preventing the fiberglass from sticking to your mold. Wax-based mold release agents are commonly used, but PVA (polyvinyl alcohol) release agents offer superior release and are particularly useful for intricate molds. Apply several coats, allowing each coat to dry completely before applying the next.

Mold Material

You'll need a material to create the shape of your enclosure. Common options include:

- Masking Tape: Multiple layers of masking tape over the area where you want the sub box.

- Fleece or Cloth: Stretched over a frame and then saturated with resin to create a solid base. This is a popular method for complex shapes.

- Cardboard: Can be used for simpler shapes and is easily cut and modified.

- Foam: Can be carved into complex shapes and then coated with fiberglass. Be sure to use a foam that is compatible with fiberglass resin.

Tools

Here's a list of essential tools:

- Mixing Buckets and Sticks: For accurately mixing the resin and hardener. Use disposable containers to avoid cleanup hassles.

- Paint Brushes or Rollers: For applying the resin to the fiberglass cloth or mat. Chip brushes are inexpensive and disposable.

- Scissors or Utility Knife: For cutting the fiberglass cloth or mat.

- Sanding Tools: Sandpaper in various grits (80, 120, 220), a sanding block, and potentially an orbital sander for larger areas.

- Respirator and Gloves: Essential for protecting yourself from the harmful fumes and chemicals in the resin.

- Eye Protection: Safety glasses or goggles to protect your eyes from splashes.

- Measuring Cups: For accurately measuring resin and hardener.

- Stir Sticks: For thoroughly mixing the resin and hardener.

- Clamps: To hold pieces together while the resin cures.

- Body Filler (Optional): For smoothing out imperfections in the finished enclosure.

- Carpet or Vinyl (Optional): For finishing the enclosure.

Step-by-Step Guide to Building a Fiberglass Sub Box

- Preparation: Thoroughly clean the area where you'll be working. Cover surfaces with plastic sheeting to protect them from resin spills. Gather all your materials and tools. Ensure you have adequate ventilation and are wearing your respirator, gloves, and eye protection.

- Creating the Mold: This is a critical step. If you're using masking tape, apply several layers to the area, ensuring a smooth and even surface. If you're using fleece or cloth, stretch it tightly over a frame and secure it in place. If using cardboard or foam, carefully cut and shape it to the desired dimensions.

- Applying Mold Release: Apply several coats of mold release agent to the mold surface, allowing each coat to dry completely. This will prevent the fiberglass from sticking to the mold.

- First Layer of Fiberglass: Mix a small batch of resin and hardener according to the manufacturer's instructions. Apply a thin layer of resin to the mold surface. Then, lay down a layer of fiberglass mat or cloth. Use a brush or roller to saturate the fiberglass with resin, working out any air bubbles.

- Subsequent Layers: Repeat the process of applying resin and fiberglass, layering multiple layers to build up the desired thickness. Alternate between fiberglass mat and cloth for added strength. Allow each layer to cure partially before applying the next. Typically, 3-4 layers are recommended for a sturdy sub box.

- Curing: Allow the fiberglass to cure completely. The curing time will vary depending on the type of resin used and the ambient temperature. Consult the manufacturer's instructions for recommended curing times.

- Removing the Mold: Once the fiberglass is fully cured, carefully remove it from the mold. Use a pry bar or screwdriver if necessary, but be careful not to damage the enclosure.

- Trimming and Sanding: Trim any excess fiberglass from the edges of the enclosure. Sand the surface to smooth out any imperfections. Start with a coarse grit sandpaper (80 grit) and gradually work your way up to a finer grit (220 grit).

- Applying Body Filler (Optional): If there are any significant imperfections in the surface, apply body filler to fill them in. Sand the body filler smooth after it has dried.

- Finishing: Choose your desired finish. You can paint the enclosure, wrap it in carpet or vinyl, or leave it as bare fiberglass. If painting, apply a primer coat first. If wrapping, use a high-quality adhesive to secure the material to the enclosure.

- Installing the Subwoofer: Cut a hole in the enclosure to accommodate the subwoofer. Use a jigsaw or router for a clean cut. Mount the subwoofer in the enclosure, ensuring a tight seal.

- Wiring and Installation: Wire the subwoofer to your amplifier. Install the sub box in your vehicle, securing it in place to prevent it from moving around.

Real-World Owner Experiences

Many DIY car audio enthusiasts have successfully built their own fiberglass sub boxes. They often share these tips and insights:

- Ventilation is Key: Emphasize the importance of working in a well-ventilated area due to the fumes from the resin.

- Patience is a Virtue: Building a fiberglass sub box takes time and patience. Don't rush the process.

- Experiment with Molds: Experiment with different mold materials to find what works best for your project.

- Layering Technique: Focus on achieving proper saturation of the fiberglass with resin to ensure maximum strength.

- Finishing Touches Matter: Invest time in the finishing process to create a professional-looking enclosure.

Frequently Asked Questions (FAQs)

Here are some common questions about building fiberglass sub boxes:

- How much does it cost to build a fiberglass sub box?

- The cost can vary widely depending on the size and complexity of the box, as well as the materials used. A basic project can cost anywhere from $50 to $200.

- How long does it take to build a fiberglass sub box?

- The build time can also vary, but expect to spend several days on the project, allowing ample time for curing.

- Is it difficult to build a fiberglass sub box?

- It can be challenging for beginners, but with careful planning, patience, and attention to detail, it's a manageable project.

- What type of resin should I use?

- Polyester resin is a good choice for beginners due to its ease of use and lower cost. Epoxy resin offers greater strength and moisture resistance but is more expensive and requires more precise mixing.

- How many layers of fiberglass should I use?

- A minimum of 3-4 layers is recommended for a sturdy sub box. More layers can be added for increased strength.

- How do I prevent the fiberglass from sticking to the mold?

- Apply several coats of mold release agent to the mold surface, allowing each coat to dry completely.

- What if I get resin on my skin?

- Wash the affected area immediately with soap and water. Avoid using solvents, as they can irritate the skin.