How To Bypass A Maf Sensor

The dreaded check engine light illuminates, and a quick scan reveals a fault code pointing to the Mass Airflow (MAF) sensor. Suddenly, your car feels sluggish, fuel economy plummets, and the engine idles roughly. The immediate question that springs to mind is: can I bypass the MAF sensor? While a permanent bypass isn't recommended, understanding how to temporarily circumvent it, and why, can be invaluable in diagnosing issues or getting you home in a pinch.

The Problem: A Failed MAF Sensor

Imagine your engine is a demanding chef, meticulously crafting culinary masterpieces (combustion) using precise ingredient measurements (air and fuel). The MAF sensor is the chef's trusted scale, measuring the amount of air entering the engine. This measurement is crucial because the engine control unit (ECU) uses it to determine the precise amount of fuel to inject for optimal combustion. A faulty MAF sensor provides inaccurate readings, leading to an incorrect air/fuel mixture. This can result in a lean condition (too much air, not enough fuel), causing hesitation, misfires, and potential engine damage. Conversely, a rich condition (too much fuel, not enough air) leads to poor fuel economy, black smoke, and potentially fouled spark plugs.

How MAF Sensors Work: A Deep Dive

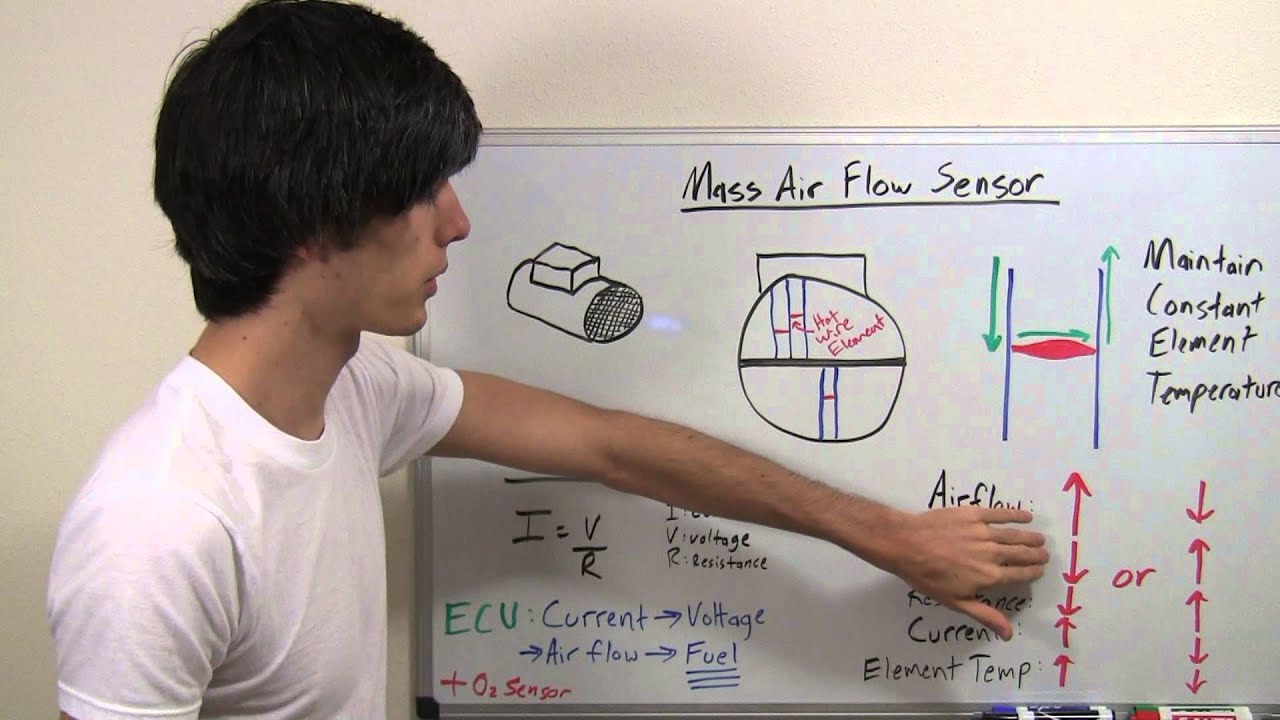

MAF sensors come in a few primary flavors, but the most common types are hot-wire and hot-film. Let's focus on the hot-wire type, as it's more prevalent:

The Hot-Wire Principle

The hot-wire MAF sensor contains a thin wire (usually platinum) that is heated to a constant temperature, typically around 200°C (392°F). As air flows past the wire, it cools it down. The sensor's internal circuitry compensates for this cooling effect by increasing the electrical current flowing through the wire, thus maintaining its constant temperature. The amount of current required to maintain this temperature is directly proportional to the mass of air flowing through the sensor. The ECU then uses this current value to calculate the mass of air entering the engine. A hot-film MAF works on a similar principle but uses a thin-film resistor instead of a wire.

Sensor Signals and Inputs

Typically, a MAF sensor has four or five wires. These include:

- Power Supply: Usually a 12V or 5V source from the ECU.

- Ground: Provides the electrical return path.

- Signal Output: A voltage signal that varies with airflow. This is the key output read by the ECU.

- Intake Air Temperature (IAT): Some MAF sensors integrate an IAT sensor to measure the temperature of the incoming air. This helps the ECU further refine the air/fuel mixture calculations, as air density changes with temperature.

- Burn-off Circuit: Some models include a burn-off circuit that briefly heats the hot-wire to a very high temperature after the engine is shut off. This helps to burn off any contaminants that may have collected on the wire, ensuring accurate readings for the next start.

Bypassing the MAF: Not a Permanent Solution

It's crucial to understand that "bypassing" a MAF sensor is generally a temporary measure intended for diagnostic purposes or emergency situations. There isn't a true "bypass" in the sense of completely removing the sensor and the engine still operating normally. The ECU relies heavily on the MAF signal, and removing it entirely will typically result in a no-start condition or severe driveability issues.

The Limp Mode Scenario

When the ECU detects a MAF sensor failure, it will often enter limp mode (also known as "fail-safe" mode). In this mode, the ECU ignores the MAF sensor reading and relies on pre-programmed default values for air/fuel mixture calculations. This is a safety measure to prevent engine damage, but it significantly reduces engine power and limits vehicle speed. This is not a bypass, but it's the car's response to a failure.

Simulating a MAF Signal: A Risky Maneuver

The closest thing to bypassing a MAF sensor involves simulating a MAF signal. This is typically done by providing the ECU with a fixed voltage signal that corresponds to a specific airflow value. This can be achieved using a potentiometer (variable resistor) to adjust the voltage sent to the ECU. However, this is a delicate process that requires a thorough understanding of the MAF sensor's voltage output characteristics for your specific vehicle. Providing the wrong voltage can damage the ECU or result in severe engine problems. This is generally not recommended for inexperienced individuals.

Why is it not recommended? The ECU is a sophisticated piece of technology. It learns and adapts to different driving conditions. By feeding it a fixed value, you are essentially lying to the computer about the amount of air it's getting. That means the other sensors are not being used correctly and that can result in long term damage to the engine.

Pros and Cons of MAF Sensor Manipulation

Pros (Temporary Diagnostic Use):

- Diagnosis: Can help determine if a MAF sensor is truly faulty by comparing engine performance with and without the simulated signal.

- Emergency Driving: In a remote location, simulating a signal might allow you to drive to a repair shop if the limp mode severely restricts your speed and range.

Cons (Permanent or Improper Use):

- Engine Damage: Incorrect air/fuel mixtures can lead to detonation, pre-ignition, and melted pistons.

- Catalytic Converter Damage: Rich conditions can overwhelm the catalytic converter, leading to overheating and failure.

- Poor Fuel Economy: Inaccurate fuel calculations result in wasted fuel.

- Emissions Failure: Bypassing the MAF sensor will almost certainly cause you to fail emissions tests.

- ECU Damage: Incorrect voltage signals can damage the ECU's sensitive electronics.

- Check Engine Light: While attempting to "bypass" the system, new and potentially misleading error codes may arise.

Use Cases and Manufacturer Examples

MAF sensor issues are common across a wide range of vehicle manufacturers. Here are some examples:

- BMW: BMWs are known for their finicky MAF sensors, especially on older models. Symptoms often include rough idling, hesitation during acceleration, and a "lean" fault code.

- Volkswagen/Audi (VAG): VAG vehicles, particularly those with turbochargers, are susceptible to MAF sensor failures due to the increased airflow and potential for contamination.

- Ford: Ford trucks and SUVs can experience MAF sensor issues due to exposure to dirt and debris, especially in off-road conditions.

- General Motors (GM): GM vehicles, including Chevrolets and GMCs, can suffer from MAF sensor problems related to oil contamination from poorly maintained air filters.

In these cases, dealerships and independent mechanics typically recommend replacement of the MAF sensor with a new or remanufactured unit. There are 3rd party manufacturers and OEM manufacturers. In some cases, OEM provides a higher quality sensor with less issues.

Real-World Insights and Recommendations

While attempting to bypass or simulate a MAF sensor signal might seem like a quick fix, it's rarely a viable long-term solution. The risks associated with incorrect air/fuel mixtures far outweigh any potential benefits, especially on modern vehicles with sophisticated engine management systems.

Recommendations:

- Proper Diagnosis: Before attempting any bypass methods, thoroughly diagnose the problem. Use a scan tool to read fault codes, and visually inspect the MAF sensor for damage or contamination.

- Cleaning the MAF Sensor: Sometimes, a dirty MAF sensor can cause inaccurate readings. Try cleaning the sensor with a MAF sensor cleaner (available at auto parts stores). Do not use carb cleaner or other solvents, as they can damage the sensitive components.

- Professional Repair: If cleaning doesn't resolve the issue, consult a qualified mechanic for a professional diagnosis and repair. Replacing the MAF sensor is usually the best course of action.

- OEM vs. Aftermarket: When replacing the MAF sensor, consider using an original equipment manufacturer (OEM) part or a reputable aftermarket brand. Cheaper aftermarket sensors may not meet the same quality standards and could lead to future problems.

- Data Logging: During the diagnosis and repair phase, data logging with a scan tool can be extremely helpful. This allows you to monitor the MAF sensor's output in real-time and identify any anomalies.

Ultimately, the MAF sensor is a crucial component of your engine's management system. While understanding how it works and the potential for temporary manipulation can be useful, prioritizing proper diagnosis and repair is always the best approach to ensure long-term engine health and performance.