How To Change A Clutch Slave Cylinder

Let's talk about the clutch slave cylinder. It's a critical, yet often overlooked, component in a manual transmission vehicle. If you're experiencing difficulty shifting, a soft or spongy clutch pedal, or trouble getting your car into gear, chances are your slave cylinder is the culprit. Replacing it is a job a seasoned DIYer can tackle, saving you a hefty bill from the mechanic. This guide provides a comprehensive, hands-on approach to replacing your clutch slave cylinder, ensuring a smooth and successful repair.

Background: The Clutch System and the Slave Cylinder's Role

To understand the slave cylinder, you need to grasp the basics of a manual clutch system. At its heart, the clutch is a mechanical device that connects and disconnects the engine from the transmission. This allows you to change gears while the engine is running. Here's the chain of events:

- When you press the clutch pedal, it actuates the clutch master cylinder. The master cylinder is a hydraulic pump that converts the mechanical force from your foot into hydraulic pressure.

- This hydraulic pressure is then transmitted through a hydraulic line (the clutch line) to the clutch slave cylinder.

- The slave cylinder, mounted on the transmission bellhousing, receives this pressure and converts it back into mechanical movement.

- This mechanical movement pushes a pushrod, which in turn acts on the clutch fork or release lever.

- The clutch fork pivots, pushing the throw-out bearing (also known as the release bearing) against the pressure plate.

- The pressure plate disengages from the friction disc (also called the clutch disc), separating the engine's power from the transmission.

In essence, the slave cylinder is the final link in the hydraulic chain, responsible for translating the hydraulic pressure into the physical force needed to disengage the clutch.

Technical Breakdown: How the Slave Cylinder Works

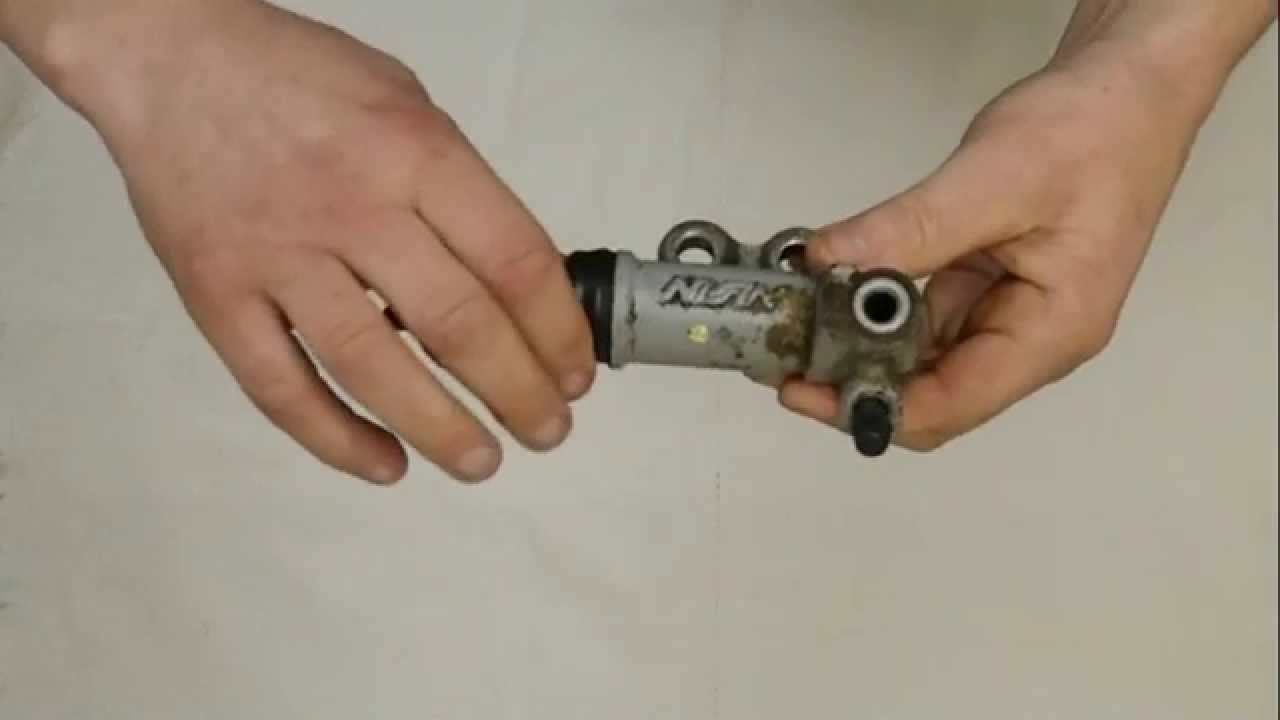

The clutch slave cylinder is a relatively simple device, but understanding its internal workings is crucial for troubleshooting and repair. It consists primarily of a cylindrical housing, a piston, a seal, and a bleed screw.

- Cylinder Housing: This is the main body of the slave cylinder, typically made of cast iron or aluminum. It houses the piston and provides a secure mounting point on the transmission.

- Piston: The piston is a cylindrical component that slides within the cylinder bore. It's responsible for converting hydraulic pressure into mechanical force. When hydraulic fluid enters the cylinder, it pushes against the piston, causing it to move.

- Seal: A rubber seal (often an O-ring) is fitted around the piston to prevent hydraulic fluid from leaking past it. A damaged or worn seal is a common cause of slave cylinder failure.

- Pushrod: The pushrod is connected to the piston and extends out of the slave cylinder. It's the component that directly actuates the clutch fork.

- Bleed Screw: The bleed screw is a small valve located on the slave cylinder. It's used to remove air from the hydraulic system after repairs or when bleeding the clutch. Air in the system can compress, leading to a spongy clutch pedal and difficulty shifting.

When you press the clutch pedal, hydraulic fluid from the master cylinder enters the slave cylinder, pushing the piston and extending the pushrod. This action disengages the clutch. When you release the pedal, the pressure decreases, and a return spring within the clutch assembly pushes the piston back into the slave cylinder, re-engaging the clutch.

Common Issues and Maintenance Concerns

Slave cylinders are generally reliable, but they can fail over time. Here are some common issues and maintenance considerations:

- Leaks: The most common problem is a leak in the hydraulic system. This can be caused by a damaged seal within the slave cylinder, a corroded cylinder bore, or a leak in the hydraulic line. A leak will result in a loss of hydraulic pressure, leading to a soft or spongy clutch pedal and difficulty shifting. Look for signs of fluid leakage around the slave cylinder or on the ground beneath the vehicle.

- Internal Corrosion: Moisture and contaminants in the hydraulic fluid can lead to corrosion within the slave cylinder. This corrosion can damage the cylinder bore and the piston, causing it to bind or leak. Regular clutch fluid flushes help prevent this.

- Air in the System: Air can enter the hydraulic system through leaks or during repairs. Air is compressible, unlike hydraulic fluid, which means it will absorb some of the force applied to the clutch pedal. This results in a spongy pedal and difficulty disengaging the clutch completely. Bleeding the clutch system is essential to remove air.

- Sticking Piston: Over time, the piston can become stuck within the cylinder bore due to corrosion or debris. This can cause the clutch pedal to feel stiff or unresponsive.

- Hydraulic Fluid Contamination: Using the incorrect type of hydraulic fluid or allowing contaminants into the system can damage the seals and other components. Always use the manufacturer-recommended hydraulic fluid.

Preventative maintenance is key to extending the life of your clutch slave cylinder. This includes regular inspection of the hydraulic system for leaks, flushing the clutch fluid every 2-3 years (or as recommended by the manufacturer), and using the correct type of hydraulic fluid.

Replacing the Clutch Slave Cylinder: A Step-by-Step Guide

Now let's get down to the nitty-gritty of replacing the slave cylinder. Before you start, gather your tools and supplies:

- New clutch slave cylinder (ensure it's the correct part for your vehicle)

- Wrench set (metric or SAE, depending on your vehicle)

- Flare nut wrench (to prevent damaging the hydraulic line fitting)

- Screwdrivers (Phillips and flathead)

- Hydraulic fluid (DOT 3 or DOT 4, as specified by your vehicle)

- Clear tubing

- A container to catch brake fluid

- Gloves

- Safety glasses

- Penetrating oil (optional, for stubborn bolts)

- Shop towels

Step 1: Preparation and Safety

Safety first! Disconnect the negative terminal of the battery to prevent any electrical accidents. Wear safety glasses to protect your eyes from brake fluid, which is corrosive. Park your car on a level surface, engage the parking brake, and use wheel chocks for added safety.

Step 2: Accessing the Slave Cylinder

The location of the slave cylinder varies depending on the vehicle. Typically, it's mounted on the transmission bellhousing, near where the transmission connects to the engine. You may need to remove some underbody panels or other components to gain access. Consult your vehicle's repair manual for specific instructions.

Step 3: Disconnecting the Hydraulic Line

This is a crucial step. Use a flare nut wrench to loosen the hydraulic line fitting that connects to the slave cylinder. Flare nut wrenches are designed to grip the fitting securely, preventing it from rounding off. If the fitting is stuck, apply penetrating oil and let it soak for a few minutes. Once the fitting is loose, carefully disconnect the hydraulic line. Be prepared for brake fluid to leak out. Place a container underneath to catch the fluid.

Important: Prevent brake fluid from spilling onto painted surfaces, as it can damage the paint. Wipe up any spills immediately.

Step 4: Removing the Old Slave Cylinder

The slave cylinder is usually held in place by two bolts. Use the appropriate wrench to remove these bolts. Once the bolts are removed, you should be able to remove the slave cylinder from the bellhousing. Note the position of the pushrod and any shims that may be present. You'll need to reinstall these in the same way.

Step 5: Installing the New Slave Cylinder

Before installing the new slave cylinder, inspect the mounting surface on the transmission bellhousing and clean it if necessary. Install the new slave cylinder, ensuring the pushrod is correctly positioned. Tighten the mounting bolts to the manufacturer's specified torque. If you're unsure of the torque specification, consult your vehicle's repair manual. Be careful not to overtighten the bolts, as this can damage the bellhousing.

Step 6: Connecting the Hydraulic Line

Carefully reconnect the hydraulic line to the new slave cylinder. Ensure the fitting is properly aligned and tighten it securely using a flare nut wrench. Again, avoid overtightening. A snug fit is sufficient.

Step 7: Bleeding the Clutch System

This is the most important step to ensure proper clutch operation. You need to bleed the clutch system to remove any air that may have entered the hydraulic lines. Here's how:

- Locate the bleed screw on the slave cylinder.

- Attach one end of the clear tubing to the bleed screw and submerge the other end in a container of brake fluid. This prevents air from being drawn back into the system.

- Have a helper slowly pump the clutch pedal several times and hold it down.

- While your helper is holding the pedal down, open the bleed screw slightly. You should see brake fluid and possibly air bubbles flowing through the tubing.

- Close the bleed screw before your helper releases the clutch pedal.

- Repeat steps 3-5 until no more air bubbles appear in the fluid flowing through the tubing.

- Check the fluid level in the clutch master cylinder reservoir regularly and top it off as needed.

Note: Be patient and persistent. It may take several attempts to completely bleed the system.

Step 8: Testing and Final Checks

Once you've bled the clutch system, test the clutch pedal feel. It should be firm and responsive. Start the engine and try shifting through all the gears. The clutch should engage and disengage smoothly. If you experience any difficulty shifting or a spongy pedal, repeat the bleeding process.

Inspect the hydraulic line fittings and the slave cylinder for any leaks. Top off the clutch master cylinder reservoir to the correct level. Reinstall any underbody panels or other components that you removed. Reconnect the negative terminal of the battery.

Do's and Don'ts / Best Practices

- Do use a flare nut wrench to disconnect the hydraulic line. This will prevent damage to the fitting.

- Do bleed the clutch system thoroughly after replacing the slave cylinder.

- Do use the correct type of hydraulic fluid for your vehicle.

- Do wear safety glasses and gloves to protect yourself from brake fluid.

- Don't overtighten any of the fittings or bolts.

- Don't allow brake fluid to spill onto painted surfaces.

- Don't reuse old hydraulic fluid.

- Don't start the engine until you've bled the clutch system.

Best Practice: Consider replacing both the clutch master cylinder and the clutch slave cylinder at the same time. If one is failing, the other may be on its way out as well. This will save you time and effort in the long run.

Conclusion

Replacing a clutch slave cylinder is a manageable task for the experienced DIYer. By following these steps carefully and paying attention to detail, you can successfully replace your slave cylinder and restore proper clutch operation. If you are unsure about any part of the process, consult your vehicle's repair manual or seek assistance from a qualified mechanic. Remember, proper maintenance and prompt repairs are essential for keeping your manual transmission vehicle running smoothly for years to come. We strongly recommend bleeding the system until you see absolutely no bubbles appear to ensure proper function. Good luck!