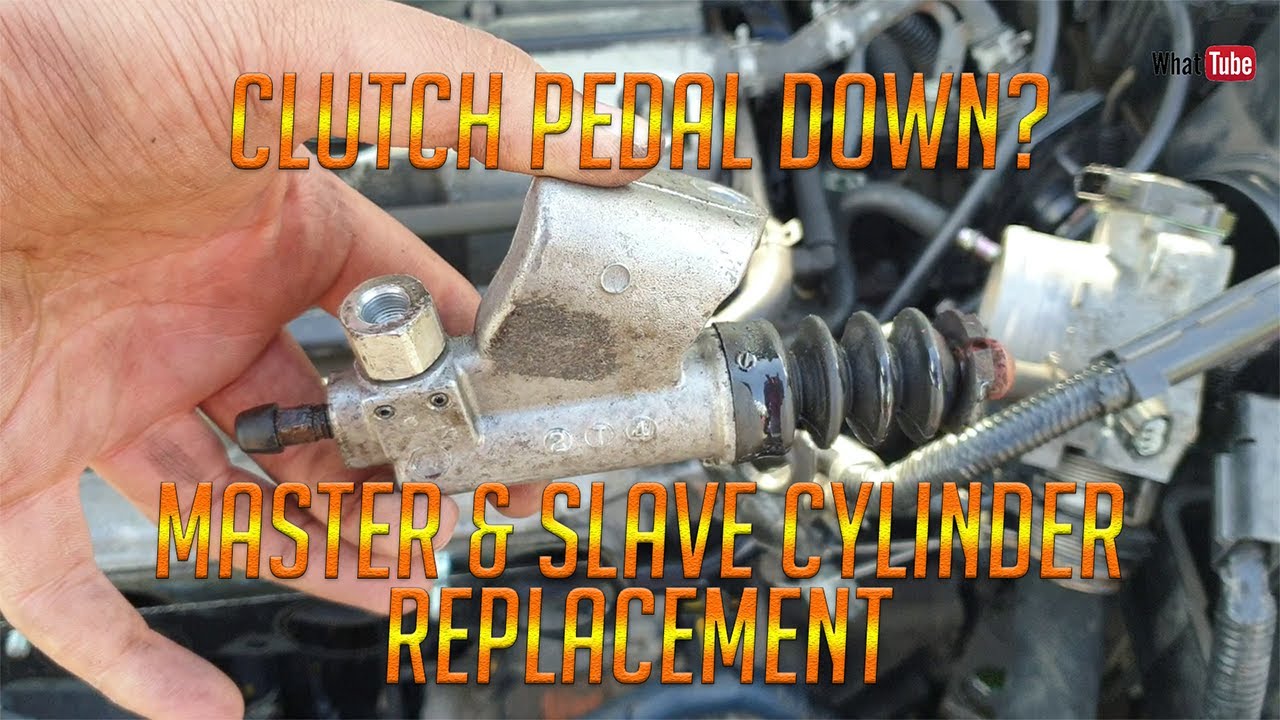

How To Change A Slave Cylinder

Facing clutch problems with your manual transmission vehicle? A common culprit is a failing slave cylinder. This article will guide you through understanding the symptoms, causes, and solutions for a faulty slave cylinder, empowering you to either tackle the repair yourself or make informed decisions at the mechanic.

Problem: Clutch Issues? Your Slave Cylinder Might Be the Culprit

The slave cylinder is a critical component in your manual transmission's hydraulic clutch system. It's responsible for transferring the force from your clutch pedal to the clutch fork, which disengages the clutch and allows you to shift gears. When the slave cylinder fails, you'll experience difficulty shifting, a soft clutch pedal, or even complete clutch failure. Addressing this promptly is crucial because continued operation with a failing slave cylinder can lead to further damage to your transmission, clutch, and other related components. The importance of a functioning slave cylinder cannot be overstated; it's the key to smooth and reliable shifting.

Symptoms of a Failing Slave Cylinder

Recognizing the symptoms early can save you time and money. Here are the most common signs of a failing slave cylinder:

- Difficulty Shifting Gears: This is often the first and most noticeable symptom. You might find it hard to get the car into gear, especially first gear or reverse.

- Soft or Spongy Clutch Pedal: The clutch pedal might feel unusually soft or spongy when you press it. This indicates a loss of hydraulic pressure within the system.

- Clutch Pedal Sticking to the Floor: In some cases, the clutch pedal might get stuck in the depressed position and require you to manually pull it back up.

- Clutch Slippage: You might experience clutch slippage, where the engine revs up without a corresponding increase in speed. This happens when the clutch isn't fully engaging due to insufficient pressure from the slave cylinder.

- Fluid Leaks: Inspect the area around the slave cylinder (usually located near the transmission) for signs of brake fluid leaks. This is a clear indication of a failing seal within the cylinder. Brake fluid leaks are not only indicative of a problem but also pose a safety hazard by potentially compromising brake performance.

- Grinding Noises When Shifting: You might hear grinding noises when trying to shift gears, especially if the clutch isn't fully disengaging.

- Inability to Shift into Gear: In severe cases, the slave cylinder might fail completely, leaving you unable to shift into any gear.

Understanding the Root Cause

The slave cylinder is a relatively simple hydraulic device. It consists of a cylinder, a piston, seals, and a pushrod. The master cylinder, located at the clutch pedal, sends hydraulic fluid under pressure to the slave cylinder when the pedal is depressed. This pressure moves the piston within the slave cylinder, which in turn pushes the pushrod against the clutch fork. The clutch fork then disengages the clutch. The most common causes of slave cylinder failure are:

- Worn Seals: Over time, the seals inside the slave cylinder can degrade and leak, leading to a loss of hydraulic pressure. These seals are constantly exposed to heat, friction, and brake fluid, causing them to wear down.

- Contaminated Brake Fluid: Old or contaminated brake fluid can damage the seals and internal components of the slave cylinder. Moisture absorbed by the brake fluid can lead to corrosion and premature wear. Always use the correct type of brake fluid as specified in your vehicle's owner's manual.

- Corrosion: Moisture and contaminants can cause corrosion inside the cylinder, leading to piston sticking and seal damage. This is especially common in vehicles that operate in humid environments or are stored for extended periods.

- Physical Damage: Impacts or debris can damage the cylinder housing or pushrod, leading to leaks or malfunctions.

- Age: Like any mechanical component, slave cylinders have a lifespan. They simply wear out over time due to constant use and exposure to harsh conditions.

What Happens If Ignored?

Ignoring a failing slave cylinder can lead to several complications:

- Complete Clutch Failure: Eventually, the slave cylinder will fail completely, leaving you stranded with a vehicle that cannot be shifted.

- Damage to the Clutch: Insufficient pressure from the slave cylinder can cause the clutch to slip, leading to premature wear and damage to the clutch disc, pressure plate, and flywheel.

- Damage to the Transmission: Forcing shifts with a failing slave cylinder can damage the synchronizers and other internal components of the transmission, leading to costly repairs.

- Safety Hazard: Difficulty shifting can create dangerous driving situations, especially in heavy traffic or emergency situations.

- Master Cylinder Damage: A failing slave cylinder can put extra strain on the master cylinder, potentially causing it to fail as well.

Recommended Fixes

The most common and recommended fix is to replace the slave cylinder. While rebuilding the slave cylinder is possible in some cases, it's often more cost-effective and reliable to replace the entire unit. Here's a step-by-step overview of the replacement process:

- Gather Your Tools and Materials: You'll need a new slave cylinder, brake fluid (the correct type for your vehicle), wrenches, sockets, a brake bleeder kit (or a helper), safety glasses, and gloves.

- Locate the Slave Cylinder: The slave cylinder is typically located on the transmission housing, near the clutch fork. Consult your vehicle's repair manual for the exact location.

- Disconnect the Hydraulic Line: Carefully disconnect the hydraulic line from the slave cylinder. Be prepared for brake fluid to leak out, and have a rag handy to catch it. Use the correct size wrench to avoid damaging the fitting.

- Remove the Old Slave Cylinder: Unbolt the slave cylinder from the transmission housing. Note the orientation of the cylinder and any shims that may be present.

- Install the New Slave Cylinder: Install the new slave cylinder in the same orientation as the old one. Use any shims that were present. Tighten the mounting bolts to the specified torque.

- Connect the Hydraulic Line: Carefully reconnect the hydraulic line to the slave cylinder. Tighten the fitting securely.

- Bleed the Clutch System: Bleeding the clutch system is crucial to remove any air from the hydraulic lines. Use a brake bleeder kit or have a helper pump the clutch pedal while you open and close the bleeder valve on the slave cylinder. Continue bleeding until no air bubbles are present in the fluid.

- Test the Clutch: Start the engine and test the clutch. Ensure that you can shift smoothly into all gears. Check for leaks around the slave cylinder and hydraulic line.

Important Considerations:

- Safety First: Always wear safety glasses and gloves when working with brake fluid. Brake fluid is corrosive and can damage your skin and eyes.

- Cleanliness: Keep all parts and surfaces clean to prevent contamination of the hydraulic system.

- Torque Specifications: Use a torque wrench to tighten all bolts and fittings to the specified torque. Over-tightening can damage the components.

- Bench Bleeding: Some slave cylinders are easier to bleed if you "bench bleed" them before installation. This involves manually pushing the piston in and out while submerged in brake fluid to remove air.

- Master Cylinder Inspection: Consider inspecting the master cylinder as well. If the slave cylinder failed due to contaminated fluid, the master cylinder may also be affected.

Cost Estimates and Shop Advice

The cost of replacing a slave cylinder can vary depending on the vehicle make and model, the price of the replacement part, and labor costs. The slave cylinder itself typically costs between $50 and $200. Labor costs can range from $100 to $300, depending on the complexity of the job and the hourly rate of the mechanic. The total cost, therefore, can range from $150 to $500.

DIY vs. Professional Repair: If you're comfortable working on cars and have the necessary tools and skills, you can save money by replacing the slave cylinder yourself. However, if you're not experienced with automotive repairs, it's best to take your vehicle to a qualified mechanic. Improper installation or bleeding can lead to further damage and safety hazards.

When choosing a mechanic:

- Read reviews: Look for shops with positive reviews and a good reputation.

- Get a quote: Obtain a written estimate before authorizing any repairs.

- Ask questions: Don't hesitate to ask the mechanic about their experience with slave cylinder replacements and the quality of the parts they use.

Credibility and Common Failure Points

While there isn't a single, universally applicable TSB (Technical Service Bulletin) covering all slave cylinder failures, manufacturers often release TSBs addressing specific issues related to clutch hydraulics in certain models. Searching online forums dedicated to your specific vehicle make and model can provide valuable insights into common failure points and potential solutions. Many owners report slave cylinder failures between 80,000 and 150,000 miles, but this can vary depending on driving conditions and maintenance practices. The community data often proves to be a valuable resource for owners facing similar problems.

By understanding the symptoms, causes, and solutions for a failing slave cylinder, you can take proactive steps to keep your vehicle running smoothly and avoid costly repairs. Whether you choose to tackle the repair yourself or seek professional help, being informed will ensure a positive outcome.