How To Change Color Of Dash Lights

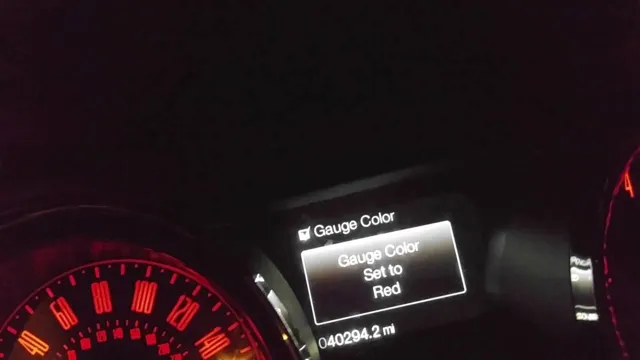

So, you're thinking about swapping out the dull glow of your dashboard lights for something a little more… *you*. Changing the color of your dash lights is a popular modification, allowing you to personalize your vehicle and improve visibility or simply create a more appealing interior ambiance. While it might seem intimidating, it's a project that's well within the reach of an experienced DIYer with the right tools, information, and a healthy dose of patience. This article will walk you through the process, covering the technical aspects, potential pitfalls, and best practices to help you achieve a professional-looking result.

Background: Illumination Architecture in Your Dashboard

Before diving into the how-to, let's understand the underlying technology. Older vehicles typically used incandescent bulbs for dash illumination. These were simple, relatively inexpensive, but inefficient and prone to burning out. Modern vehicles almost exclusively use LEDs (Light Emitting Diodes). LEDs offer several advantages: longer lifespan, lower power consumption, and the ability to produce a wider range of colors. However, they also require more sophisticated circuitry. Often, manufacturers will utilize a combination of surface mount and through-hole LEDs on a printed circuit board (PCB) to provide illumination for different gauges and displays. The way these LEDs are arranged, wired and controlled vary significantly from make to make, and even model to model within the same brand.

Understanding the existing lighting system is crucial. Some vehicles use a single LED to illuminate an entire gauge cluster via a system of light pipes (clear plastic channels that distribute light). Others might have individual LEDs for each indicator or section of a display. Some systems employ a PWM (Pulse Width Modulation) controller to adjust the brightness of the LEDs. This involves rapidly turning the LEDs on and off, varying the duty cycle (the percentage of time the LED is on) to achieve different brightness levels. This is another critical piece to understand because your replacement LEDs need to be compatible with the PWM frequency and current demands.

Technical Breakdown: The Color-Changing Process

The core of changing your dash light color involves replacing the existing LEDs with new ones of your desired color. Here’s a step-by-step breakdown:

1. Disassembly: Accessing the Dashboard

This is often the most time-consuming part. Safety first! Disconnect the negative terminal of your battery before you begin to prevent any electrical shorts or accidental airbag deployment. Consult your vehicle's service manual for the proper procedure to remove the dashboard trim and instrument cluster. Be gentle and patient. Plastic trim can be brittle, especially in older vehicles. Use trim removal tools to avoid scratching or breaking any components. Pay close attention to how everything is connected and take pictures as you go – this will be invaluable during reassembly.

2. Instrument Cluster Removal

Once the trim is out of the way, you can access the instrument cluster. Usually, this is held in place by a few screws or clips. Disconnect all electrical connectors attached to the cluster. These connectors often have locking mechanisms, so make sure you understand how to release them before pulling. Label each connector with tape to ensure you plug them back into the correct ports later. Remove the instrument cluster completely and bring it to a well-lit workspace.

3. Circuit Board Access

Now comes the delicate part. The instrument cluster housing will likely need to be disassembled to expose the PCB (Printed Circuit Board). This often involves removing screws or carefully prying open plastic tabs. Once you have access to the PCB, you'll see the LEDs that need to be replaced. Examine the LEDs carefully to determine their type. Most likely they will be SMD (Surface Mount Device) LEDs. These are tiny and require specialized soldering equipment.

4. LED Identification and Selection

Identifying the correct LED type is crucial. Common SMD LED sizes are 3528, 5050, 0805, and 1206. The numbers refer to the dimensions of the LED in millimeters (e.g., a 3528 LED is 3.5mm x 2.8mm). You can often find the LED type listed in the service manual, or you can measure them yourself with a caliper. Voltage and current requirements are also important. Choose replacement LEDs with similar voltage and current ratings to the originals. Using LEDs with significantly different ratings can damage the circuit or result in improper brightness. Note the forward voltage of the stock LED and its replacement. The forward voltage is the voltage drop across the LED when it is conducting.

5. Desoldering and Soldering

This is where the real skill comes in. You’ll need a fine-tipped soldering iron, solder, flux, and possibly desoldering braid or a desoldering pump. If you’re not comfortable with SMD soldering, consider practicing on an old circuit board first. * **Desoldering:** Apply flux to the LED leads. Heat each lead with the soldering iron until the solder melts. Use desoldering braid or a desoldering pump to remove the solder from the pads. Be careful not to overheat the PCB, as this can damage the pads. * **Soldering:** Apply a small amount of flux to the pads. Position the new LED on the pads, ensuring correct polarity (usually indicated by a small mark on the LED or PCB). Hold the LED in place with tweezers or a toothpick. Apply a small amount of solder to each lead, creating a secure connection. Make sure that the solder is making good contact with both the LED lead and the PCB pad. * IMPORTANT: Use proper ESD(Electrostatic Discharge) protection. Ground yourself to prevent damage to sensitive electronics.

6. Testing and Reassembly

Before reassembling the entire dashboard, connect the instrument cluster to the vehicle's wiring harness and turn on the ignition to test the new LEDs. If any LEDs are not working, double-check your solder joints and polarity. Once you're satisfied with the results, carefully reassemble the instrument cluster and dashboard trim, following the reverse order of disassembly. Be sure to torque any fasteners to the proper specification to avoid damaging the trim.

Common Issues and Maintenance Concerns

Even with careful execution, problems can arise. Here are some common issues and how to address them:

* **LEDs not lighting up:** Check polarity, solder joints, and voltage rating. Make sure the LEDs are compatible with the vehicle's PWM system. A resistor might be needed to manage the current draw. * **Dim or uneven lighting:** This could be due to mismatched LED brightness or damaged light pipes. * **Flickering:** Indicates PWM incompatibility, loose solder joints, or a faulty voltage regulator in the instrument cluster. * **Overheating:** Occurs from using LEDs with higher current draw than the originals. This can damage the LEDs and the surrounding circuitry. * **Damaged PCB traces:** If you overheat the PCB, you can lift or damage the copper traces. This requires careful repair using jumper wires or trace repair kits. * **Airbag light on after reassembly**: Be sure that all connectors are fully seated, and that the seat airbag sensor is properly connected. A scan tool will be needed to clear the code.Regular maintenance is generally not required after changing dash lights. However, it's a good idea to periodically inspect the LEDs for any signs of degradation or failure.

Do’s and Don’ts / Best Practices

Here's a summary of do's and don'ts to ensure a successful outcome:

* Do: Disconnect the battery before starting. * Do: Consult your vehicle's service manual for disassembly instructions. * Do: Use trim removal tools to avoid damaging plastic components. * Do: Take pictures throughout the disassembly process. * Do: Identify the correct LED type and voltage/current ratings. * Do: Use a fine-tipped soldering iron and flux. * Do: Practice soldering on an old circuit board first. * Do: Test the LEDs before reassembling everything. * Don't: Force anything. If something doesn't come apart easily, double-check the fasteners or clips. * Don't: Overheat the PCB. * Don't: Use LEDs with significantly different voltage/current ratings. * Don't: Forget to reconnect all electrical connectors. * Don’t: Reassemble anything before testing. * Don’t: Touch the LED with your bare skin before soldering. * Best Practice: If you are unsure about your soldering skills, seek professional assistance. A qualified electronics technician can perform the LED replacement for you. * Best Practice: Some shops specialize in this type of modification. While it may be more expensive than doing it yourself, it's the best solution if you lack the tools, skills, or confidence to tackle the project.Conclusion

Changing the color of your dash lights is a rewarding project that can significantly enhance the look and feel of your vehicle's interior. By understanding the underlying technology, following the steps outlined above, and adhering to best practices, you can achieve a professional-looking result. However, it's important to assess your skill level and comfort zone before tackling this project. If you're unsure about any aspect of the process, don't hesitate to seek professional assistance. A mistake can be costly and potentially damage your vehicle's electronics. If you're confident in your abilities and willing to invest the time and effort, changing your dash lights can be a fun and fulfilling DIY project.