How To Check Air Con In Car

So, you're ready to dive into your car's air conditioning system? Excellent! Maintaining a cool cabin is crucial, not just for comfort, but also for safety on long drives. This guide is designed to give you a solid understanding of how to diagnose common AC issues. We'll go beyond just adding refrigerant, focusing on understanding the key components, troubleshooting techniques, and safety precautions. Consider this your deep dive into automotive AC systems, explained clearly and concisely.

Understanding Your Car's AC System

The purpose of understanding the AC system isn't just for repairs; it's about preventative maintenance and informed decision-making. Knowing the system allows you to identify potential problems early, saving you money and preventing costly breakdowns. Imagine diagnosing a faulty compressor clutch before it destroys the compressor itself – that’s the power of knowledge.

Key Specs and Main Parts

Before we jump into troubleshooting, let’s identify the core components:

- Compressor: The heart of the system. It pressurizes the refrigerant, raising its temperature. It's driven by the engine, usually via a belt and clutch.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the high-pressure, hot refrigerant, causing it to condense into a high-pressure liquid.

- Receiver-Drier (or Accumulator): Filters the refrigerant, removing moisture and debris. It also acts as a temporary storage reservoir. Receiver-driers are typically used with expansion valves, while accumulators are used with orifice tubes. The difference is their location relative to the expansion device and their ability to store liquid refrigerant.

- Expansion Valve (or Orifice Tube): Controls the flow of high-pressure liquid refrigerant into the evaporator, causing a pressure drop and allowing the refrigerant to expand and evaporate.

- Evaporator: Located inside the cabin, the evaporator absorbs heat from the cabin air, cooling it down. The cold refrigerant boils off into a low-pressure gas.

- Refrigerant: The working fluid that absorbs and releases heat as it changes state. Common refrigerants include R-134a and the newer R-1234yf. Important: Do not mix refrigerants. They are not compatible and can cause significant damage.

- Pressure Switches: Monitor the refrigerant pressure and protect the system from damage. They can shut off the compressor if the pressure is too high or too low.

- Hoses and Lines: Transport the refrigerant between components.

How It Works

The AC system works on the principle of heat transfer using a closed-loop cycle:

- The compressor compresses the low-pressure, low-temperature refrigerant gas, increasing its pressure and temperature.

- The high-pressure, high-temperature refrigerant gas flows to the condenser, where it rejects heat to the outside air, causing it to condense into a high-pressure, high-temperature liquid.

- The high-pressure liquid refrigerant flows to the receiver-drier (or accumulator), where it is filtered and has any moisture removed.

- The high-pressure liquid refrigerant then flows to the expansion valve (or orifice tube), where it undergoes a controlled pressure drop. This causes the refrigerant to expand and partially evaporate, becoming a low-pressure, low-temperature liquid-gas mixture.

- The low-pressure, low-temperature liquid-gas mixture flows to the evaporator, where it absorbs heat from the cabin air, causing the remaining liquid refrigerant to evaporate completely into a low-pressure, low-temperature gas. This cools the cabin air, which is then blown into the passenger compartment.

- The low-pressure, low-temperature refrigerant gas flows back to the compressor, completing the cycle.

Real-World Use: Basic Troubleshooting

Okay, let’s get practical. Here are some common symptoms and how to start diagnosing them:

- No Cold Air:

- Check the Compressor Clutch: Is it engaging when the AC is turned on? You should hear a click and see the clutch plate engage. If not, check the fuse and relay for the compressor. If those are good, the clutch itself may be faulty, or there might be an electrical issue in the control circuit.

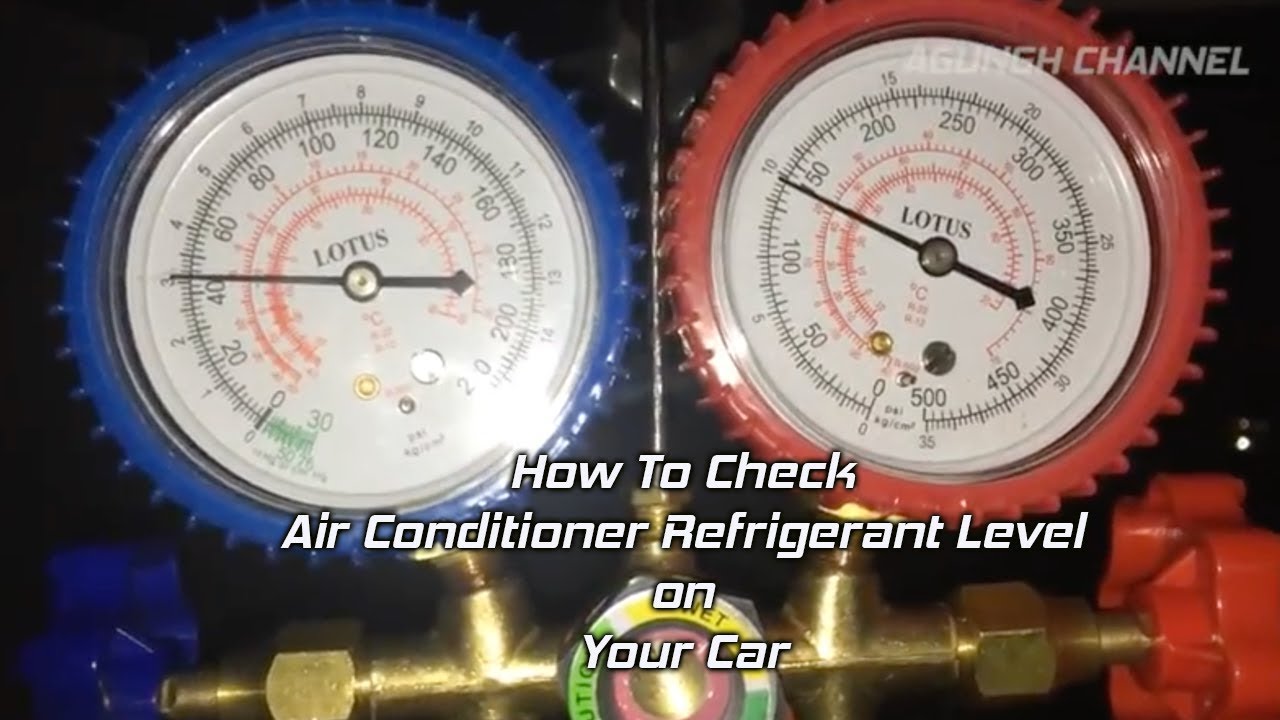

- Check Refrigerant Level: Use an AC manifold gauge set to check the high and low side pressures. Low refrigerant is a common cause. However, simply adding refrigerant without addressing the underlying leak is only a temporary fix.

- Check the Condenser Fan: Ensure the fan is running when the AC is on. A malfunctioning condenser fan reduces the condenser's ability to dissipate heat, leading to poor cooling performance.

- Check the Expansion Valve/Orifice Tube: A clogged or malfunctioning expansion valve or orifice tube can restrict refrigerant flow. This is often indicated by abnormal pressure readings on the gauge set.

- Weak Airflow:

- Check the Blower Motor: Verify that the blower motor is functioning at all speeds. A failing blower motor resistor can cause the blower to only work on high speed or not at all.

- Check the Cabin Air Filter: A clogged cabin air filter can significantly reduce airflow. Replace it regularly.

- Check for Blockages: Inspect the air ducts for any obstructions, such as debris or rodents.

- Unusual Noises:

- Squealing: Could be a slipping belt. Check the belt tension and condition.

- Rattling: Could indicate a failing compressor or loose components.

- Hissing: Might indicate a refrigerant leak. Use an electronic leak detector or soapy water to locate the source of the leak.

Using a Manifold Gauge Set: This is crucial for diagnosing AC problems. The gauge set allows you to measure the high and low side pressures, which can provide valuable information about the system's performance. Learn to interpret the readings and compare them to the manufacturer's specifications for your vehicle and refrigerant type. Remember, each refrigerant type has its own pressure/temperature characteristics.

Safety First!

Working with AC systems can be dangerous. Here are some crucial safety precautions:

- Refrigerant Burns: Refrigerant can cause severe frostbite. Always wear gloves and eye protection. If refrigerant comes into contact with your skin or eyes, flush immediately with plenty of water and seek medical attention.

- High Pressure: AC systems operate at high pressures. Never disconnect lines or components without properly discharging the system first. Use a refrigerant recovery machine to safely remove the refrigerant. It is illegal to vent refrigerant into the atmosphere.

- Electrical Hazards: Be aware of electrical components, especially around the compressor clutch. Disconnect the battery before working on any electrical components.

- Refrigerant Compatibility: Do not mix refrigerants. Using the wrong refrigerant can damage the system and potentially create a dangerous situation. Always verify the correct refrigerant type for your vehicle before adding any refrigerant.

Component-Specific Hazards:

- Compressor: The compressor clutch can engage unexpectedly, causing injury. Disconnect the power supply before working near it.

- Condenser Fan: The fan blades can cause injury if they are spinning. Ensure the fan is turned off and cannot be activated accidentally.

Proper Ventilation: Always work in a well-ventilated area to avoid inhaling refrigerant fumes.

Seek Professional Help: If you're not comfortable working on AC systems, or if you encounter a complex problem, it's best to seek professional help from a qualified AC technician.

By understanding the fundamentals, practicing safe procedures, and using the right tools, you can confidently tackle many common AC problems. Remember that preventative maintenance is key. Regularly inspect your system for leaks, check the belt tension, and replace the cabin air filter to keep your AC running smoothly for years to come.

We have a detailed AC system diagram available for download. This diagram will help you visualize the system and identify the location of each component. It also includes information on the wiring diagrams related to the system, which is vital for troubleshooting electrical issues. Contact us to request the download link.