How To Check Fuel Injectors For Leaks

Fuel injectors, those unsung heroes of modern internal combustion engines, are responsible for delivering precisely metered amounts of fuel directly into the cylinders. When they malfunction, the consequences can range from decreased fuel economy and rough idling to outright engine failure. One common culprit? Leaking injectors. But how can you diagnose this potentially costly problem yourself? Let's dive into the process of checking fuel injectors for leaks, exploring the methods, tools, and underlying principles involved.

The Case of the Mystery Misfire: Why Injectors Leak

Imagine you're baking a cake. Instead of carefully measuring each ingredient, you're haphazardly dumping flour, sugar, and eggs into the bowl. The result? A lumpy, unevenly baked mess. A leaking fuel injector is much like that chaotic approach to baking. Instead of delivering a precisely atomized spray of fuel at the correct moment, it drips or seeps fuel into the cylinder even when it shouldn't. This throws off the air-fuel ratio, leading to a variety of symptoms.

Common symptoms of leaking fuel injectors include:

- Poor fuel economy: The engine is consuming more fuel than necessary due to the uncontrolled fuel leak.

- Rough idling: The inconsistent fuel delivery causes uneven combustion, resulting in a shaky or unstable idle.

- Difficulty starting: Excess fuel in the cylinders can "flood" the engine, making it hard to start, especially when warm.

- Fuel smell: A strong gasoline odor, especially near the engine, can indicate a fuel leak.

- Decreased performance: The incorrect air-fuel ratio leads to less efficient combustion and reduced power.

- Check engine light (CEL): The engine control unit (ECU) may detect the imbalance and trigger a CEL, often with codes related to misfires or fuel trim issues.

But why do injectors leak in the first place? There are several potential causes:

- Contamination: Debris in the fuel system, such as rust particles or varnish, can clog or damage the injector's internal components, preventing it from sealing properly.

- Wear and tear: Over time, the injector's seals and nozzle can wear down, leading to leaks.

- Corrosion: Exposure to moisture and contaminants can corrode the injector's internal parts, affecting its performance.

- Damage: Physical damage to the injector, such as cracks or breaks, can obviously cause leaks.

- O-ring failure: The O-rings that seal the injector to the fuel rail and intake manifold can degrade and leak over time.

Under the Hood: How Fuel Injectors Work

To effectively diagnose injector leaks, it's crucial to understand how these components operate. A fuel injector is essentially a sophisticated solenoid valve. When the ECU sends a signal, the solenoid energizes, lifting a needle valve off its seat. This allows pressurized fuel to spray through a precisely engineered nozzle into the intake manifold or directly into the cylinder (in direct injection systems).

The fuel pressure is maintained by the fuel pump and regulated by the fuel pressure regulator. The duration of the solenoid activation, known as the pulse width, determines the amount of fuel injected. The nozzle design is crucial for atomizing the fuel into a fine mist, which promotes efficient combustion.

In a port fuel injection (PFI) system, injectors are located in the intake manifold, spraying fuel into the intake port just before the intake valve. In a direct injection (DI) system, injectors are mounted directly into the cylinder head, injecting fuel directly into the combustion chamber. DI systems operate at much higher pressures than PFI systems (often thousands of PSI compared to 40-60 PSI), making DI injectors more complex and generally more expensive to replace.

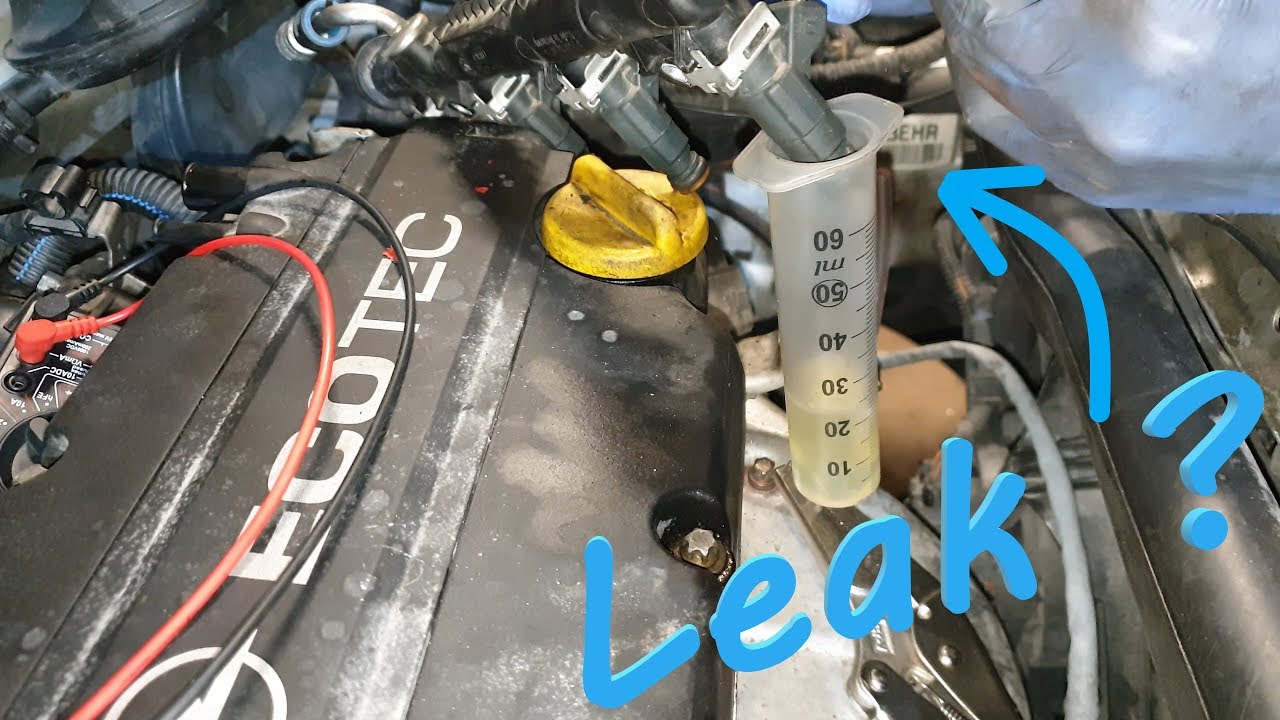

Methods for Checking Injector Leaks: From Simple to Sophisticated

There are several methods you can use to check for leaking fuel injectors, ranging from visual inspection to more advanced diagnostic techniques. Let's explore each approach:

1. The Visual Inspection: A First Line of Defense

This is the simplest and often the first step. Look for any signs of fuel leakage around the injectors, fuel rail, and intake manifold. Pay close attention to the injector O-rings. Wet spots, fuel stains, or a strong fuel odor are red flags.

Pros: Easy, requires no special tools, can quickly identify obvious leaks.

Cons: Can only detect significant leaks, difficult to access injectors in some engines, doesn't identify internal leaks.

2. The "Sniff Test": Using Your Nose

After the engine has been running and then shut off, carefully smell around each injector. A strong gasoline odor emanating from a particular injector suggests a leak.

Pros: Simple, requires only your sense of smell.

Cons: Subjective, can be difficult to pinpoint the exact source of the leak, not reliable in windy conditions.

3. The Fuel Pressure Test: Monitoring System Integrity

This test involves connecting a fuel pressure gauge to the fuel rail and monitoring the pressure after the engine is shut off. A significant drop in pressure indicates a leak somewhere in the fuel system, which could be a leaking injector, a faulty fuel pressure regulator, or a leaking fuel pump check valve.

Pros: Can identify leaks in the entire fuel system, provides quantitative data.

Cons: Requires a fuel pressure gauge, doesn't pinpoint the exact location of the leak, requires knowledge of fuel system specifications.

Example: Many older vehicles have a Schrader valve on the fuel rail for easy pressure testing. Newer vehicles might require a special adapter.

4. The Stethoscope Method: Listening for Leaks

Using a mechanic's stethoscope, listen to each injector with the engine running. A healthy injector will produce a consistent clicking sound as it opens and closes. A leaking injector may sound erratic or "wet."

Pros: Relatively simple, can help isolate the source of the leak.

Cons: Requires a mechanic's stethoscope, subjective, can be difficult to hear the injector over engine noise.

5. The Injector Balance Test: Pinpointing the Culprit

This test involves temporarily disabling each injector one at a time while the engine is running. If disabling a particular injector improves the engine's performance (e.g., smoother idling), it suggests that injector was leaking and contributing to the imbalance.

Pros: Can identify which injector is leaking, relatively straightforward.

Cons: Requires a way to safely disable each injector (e.g., disconnecting the electrical connector), can be risky if not done carefully, may trigger a CEL.

6. The Compression Test: Indirect Indication

While not a direct test for injector leaks, a compression test can sometimes reveal clues. A cylinder with abnormally low compression, especially when accompanied by other symptoms of injector leakage, may indicate that excess fuel is washing down the cylinder walls, reducing lubrication and causing increased wear.

Pros: Provides information about the overall health of the engine.

Cons: Doesn't directly test injectors, requires a compression tester, can be time-consuming.

7. Professional Injector Cleaning and Flow Testing: The Gold Standard

For a comprehensive assessment, you can remove the injectors and send them to a professional fuel injector cleaning and flow testing service. These services use specialized equipment to clean the injectors, test their flow rate, and check for leaks. They can often diagnose and repair injector problems that are difficult to detect with other methods.

Pros: Provides a thorough assessment of injector performance, can identify and correct a wide range of injector problems.

Cons: Requires removing the injectors, can be expensive, requires specialized equipment.

Manufacturer Example: Companies like Injector Dynamics and RC Engineering offer professional fuel injector services.

Real-World Considerations and Recommendations

Diagnosing fuel injector leaks can be challenging, and it's important to proceed systematically. Start with the simple visual inspection and "sniff test" before moving on to more complex procedures. If you're not comfortable working on your fuel system, it's best to consult a qualified mechanic. Remember that fuel systems operate under pressure, and improper handling can be dangerous. Always relieve fuel pressure before disconnecting any fuel lines or injectors.

When replacing fuel injectors, it's generally recommended to replace all injectors at the same time, especially if they are original to the vehicle. This ensures consistent performance and prevents future problems. Also, be sure to use high-quality replacement injectors from a reputable manufacturer. Using cheap or counterfeit injectors can lead to poor performance and even engine damage.

Regular fuel system maintenance, such as using fuel injector cleaner additives, can help prevent injector problems. These additives can help dissolve varnish and other deposits that can clog injectors. However, use these additives sparingly and follow the manufacturer's instructions carefully. In some cases, harsh fuel injector cleaners can actually damage injectors, especially on older vehicles.

Ultimately, understanding how fuel injectors work and the methods for checking them can empower you to diagnose and address fuel system problems effectively, saving you time and money in the long run.