How To Clean Car Electrical Connectors

Electrical connectors are the unsung heroes of your car's complex network, acting as the vital junctions that allow signals and power to flow seamlessly between components. When these connections falter, a cascade of issues can arise, ranging from intermittent sensor readings to complete system failure. Knowing how to properly clean and maintain these connectors is a valuable skill for any serious DIY mechanic or car enthusiast. This article will guide you through the process, offering expert tips and best practices to keep your car's electrical system humming smoothly.

The Importance of Clean Connections: A Deeper Dive

Before diving into the how-to, it’s crucial to understand why clean electrical connectors are so important. Modern vehicles rely on a sophisticated array of sensors, actuators, and control modules, all interconnected by a vast network of wiring harnesses. These harnesses terminate in connectors – often multi-pin connectors – that plug into various components.

Over time, these connectors are exposed to a harsh environment. Engine bay heat, moisture, road salt, dirt, and even the subtle effects of oxidation can all contribute to corrosion and the buildup of debris on the connector pins and within the connector housing. This contamination introduces resistance into the circuit. Resistance is the opposition to the flow of electrical current. Increased resistance translates to a weaker signal, voltage drops, and unreliable operation. In extreme cases, corrosion can completely sever the connection, leading to total component failure.

Think of it like a garden hose. If the hose is clear, water flows freely. But if it's clogged with debris, the water flow is reduced, or even stops entirely. Electrical connectors work on the same principle: clean contacts ensure unobstructed electron flow.

Technical Breakdown: How Connectors Function

Let's examine the inner workings of a typical automotive electrical connector. Most connectors consist of two main parts: a male connector (typically containing pins) and a female connector (containing receptacles). These connectors are designed to create a tight, secure fit, ensuring reliable electrical contact. Often, they include a locking mechanism (a clip or latch) to prevent accidental disconnection due to vibration or movement.

The pins and receptacles are typically made of a conductive metal, such as copper or brass, often plated with tin or gold to enhance conductivity and corrosion resistance. The connector housing is usually made of plastic, providing insulation and physical protection to the delicate electrical connections.

When the male and female connectors are mated, the pins slide into the receptacles, creating a physical connection that allows electrons to flow from one wire to another. The quality of this connection – the surface area of contact and the pressure between the surfaces – directly impacts the resistance of the circuit. Corrosion or dirt can significantly reduce the contact area and pressure, leading to increased resistance.

Furthermore, the integrity of the crimped connection between the wire and the connector pin is critical. A poor crimp can also introduce resistance or even cause the wire to pull out of the connector altogether. This is why proper crimping tools and techniques are essential when repairing or replacing electrical connectors.

Common Issues and Maintenance Concerns

Several common issues can plague automotive electrical connectors:

- Corrosion: The most frequent culprit. Exposure to moisture and road salt accelerates the oxidation of the metal contacts, forming a layer of non-conductive corrosion that blocks the flow of electricity. This often appears as a green or white powdery substance.

- Dirt and Debris: Dust, dirt, oil, and other contaminants can accumulate inside the connector housing, interfering with the contact between the pins and receptacles.

- Loose Connections: Vibration and repeated connection/disconnection cycles can loosen the fit between the connector halves, reducing contact pressure and increasing resistance. Broken locking tabs further exacerbate this issue.

- Damaged Connectors: Physical damage to the connector housing, pins, or receptacles can also compromise the connection. This could be due to impact, excessive force during disconnection, or heat damage.

- Wire Damage: The wires leading into the connector can become frayed, cracked, or even broken due to age, heat, or physical stress. This can lead to intermittent or complete circuit failure.

Regular maintenance is key to preventing these issues. Visual inspections of connectors, especially those located in exposed areas, should be part of your routine car care. Addressing any signs of corrosion or damage early can prevent more serious problems down the road.

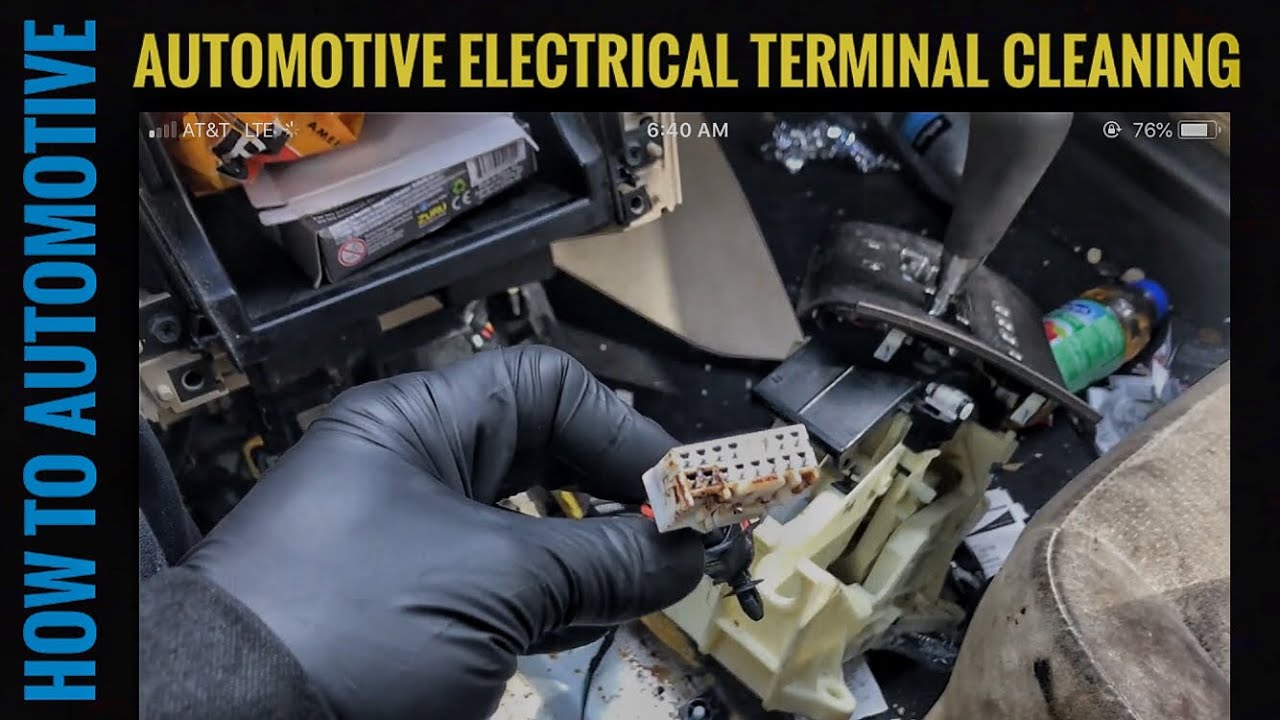

Step-by-Step Guide: Cleaning Car Electrical Connectors

Here’s a detailed, step-by-step guide to cleaning car electrical connectors:

- Safety First! Disconnect the negative battery terminal before working on any electrical components. This prevents accidental shorts and electrical shocks.

- Identify the Connector: Locate the connector you want to clean. Refer to your car's repair manual or wiring diagram if necessary. Take a picture of the connector and wiring arrangement before disconnecting it – this will help you remember how to reconnect everything properly.

- Disconnect the Connector: Carefully disconnect the connector by releasing the locking mechanism. Avoid pulling on the wires; instead, grip the connector housing firmly and gently wiggle it apart. If the connector is difficult to disconnect, try using a small screwdriver or pick to help release the locking tab. Never force the connector apart, as this can damage the pins or housing.

- Inspect the Connector: Thoroughly inspect the connector for signs of corrosion, dirt, damage, or loose wires. Pay close attention to the pins and receptacles. If you find significant damage, the connector may need to be replaced.

- Clean the Connector:

- Initial Cleaning: Use a small brush (a toothbrush or a specialized electrical contact brush) to remove loose dirt and debris from the connector housing and around the pins/receptacles.

- Contact Cleaner: Apply a liberal amount of electrical contact cleaner to both the male and female connector halves. Contact cleaner is a specialized solvent that dissolves corrosion and grease without damaging plastic or electrical components. Be sure to use a cleaner specifically designed for electrical contacts; avoid using general-purpose cleaners or solvents, as these can damage the connector.

- Scrubbing: Use the brush to scrub the pins and receptacles thoroughly. For stubborn corrosion, you can use a cotton swab or a small piece of fine-grit sandpaper (300-400 grit) to gently polish the contacts. Be very careful not to damage the pins or receptacles.

- Compressed Air: After cleaning, use compressed air to blow out any remaining debris or cleaner from the connector housing.

- Reassemble the Connector: Once the connector is clean and dry, carefully reassemble it. Ensure the locking mechanism clicks into place securely.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Test the System: Start the engine and test the system to ensure that the problem has been resolved. If the problem persists, further troubleshooting may be necessary.

Do's and Don'ts / Best Practices

- Do: Use a dedicated electrical contact cleaner.

- Do: Disconnect the battery before working on electrical components.

- Do: Inspect the connector thoroughly for damage before cleaning.

- Do: Use a small brush to scrub the pins and receptacles gently.

- Do: Use compressed air to blow out any remaining debris or cleaner.

- Do: Apply dielectric grease to the connector after cleaning to prevent future corrosion (see explanation below).

- Don't: Use excessive force when disconnecting or reconnecting connectors.

- Don't: Use general-purpose cleaners or solvents on electrical connectors.

- Don't: Use metal tools to clean connector pins, as this can damage them.

- Don't: Overlook damaged or corroded wires leading into the connector.

Dielectric Grease: A Protective Layer

Applying a thin layer of dielectric grease to the connector after cleaning is highly recommended. Dielectric grease is a non-conductive silicone-based lubricant that helps to seal out moisture and prevent corrosion. It doesn't enhance conductivity, but it prevents corrosion from forming, which ultimately ensures better conductivity over the long term. Apply a small amount of dielectric grease to the pins and receptacles before reassembling the connector.

Conclusion

Cleaning car electrical connectors is a simple yet effective way to maintain the health and reliability of your vehicle's electrical system. By following the steps outlined in this article and adhering to the best practices, you can prevent costly repairs and ensure that your car's electrical components continue to function smoothly for years to come. Regular inspection and proactive cleaning are your best defense against the hidden gremlins of corroded connections. Don't underestimate the power of a clean connection – it can make all the difference.