How To Diagnose Bad Spark Plugs

So, you think you've got a bad spark plug situation? Let's dive into diagnosing it. A misfiring engine, poor fuel economy, and rough idling can often point to spark plug issues. Knowing how to properly diagnose them yourself can save you money and prevent more serious engine problems down the line. This guide is designed for the intermediate car owner or DIY mechanic who's comfortable getting their hands dirty and wants a more in-depth understanding of spark plug diagnostics.

Purpose: Why Spark Plug Diagnostics Matter

Understanding how to diagnose bad spark plugs is crucial for several reasons:

- Cost Savings: Identifying and replacing only the faulty spark plugs saves money compared to replacing all of them preemptively.

- Improved Performance: Diagnosing and fixing spark plug issues restores engine performance, fuel economy, and reduces emissions.

- Preventative Maintenance: Early detection of spark plug problems can prevent damage to other engine components, like the ignition coils and catalytic converter.

- Troubleshooting: It's a necessary step in diagnosing overall engine misfire issues, helping you pinpoint the root cause.

- Learning: Understanding spark plug condition can provide valuable insight into the engine's overall health and operating conditions.

Key Specs and Main Parts

Before we get started, let's review the key components and specifications related to spark plugs:

Main Parts:

- Terminal: The top of the spark plug, connecting to the spark plug wire or ignition coil.

- Insulator: Usually made of ceramic, it isolates the high voltage electricity and prevents it from grounding to the engine.

- Metal Shell: The threaded portion that screws into the cylinder head. It provides a ground path and heat dissipation.

- Center Electrode: The electrode in the center of the spark plug that receives high voltage from the ignition system.

- Ground Electrode (Side Electrode): The electrode that is bent over to create a gap with the center electrode. The spark jumps across this gap.

Key Specifications:

- Gap: The distance between the center and ground electrodes. This is crucial for proper spark formation. Correct gap is usually specified in your car's owner's manual or on a sticker under the hood.

- Heat Range: A measure of how quickly the spark plug dissipates heat. Hotter plugs retain more heat, while colder plugs dissipate heat faster. Using the correct heat range is essential for engine performance and plug longevity.

- Thread Size and Reach: The diameter and length of the threaded portion of the plug. This must match the cylinder head.

- Torque Specification: The amount of torque required to properly tighten the spark plug. Over-tightening can damage the plug or cylinder head, while under-tightening can lead to leaks and poor performance.

How It Works

The spark plug's job is simple: to ignite the air/fuel mixture in the combustion chamber. Here’s a breakdown of how it works:

- The ignition coil (or distributor in older vehicles) sends a high-voltage pulse to the spark plug.

- This voltage travels through the spark plug's terminal, insulator, and down to the center electrode.

- The high voltage creates an electrical arc (spark) across the gap between the center electrode and the ground electrode.

- This spark ignites the compressed air/fuel mixture in the combustion chamber.

- The resulting explosion pushes the piston down, driving the crankshaft and ultimately powering the wheels.

A properly functioning spark plug produces a strong, consistent spark at the precise moment required by the engine's timing. This ensures complete combustion, optimal performance, and minimal emissions.

Real-World Use: Troubleshooting Tips

Now, let's get to the practical part: diagnosing bad spark plugs. Here's a step-by-step approach:

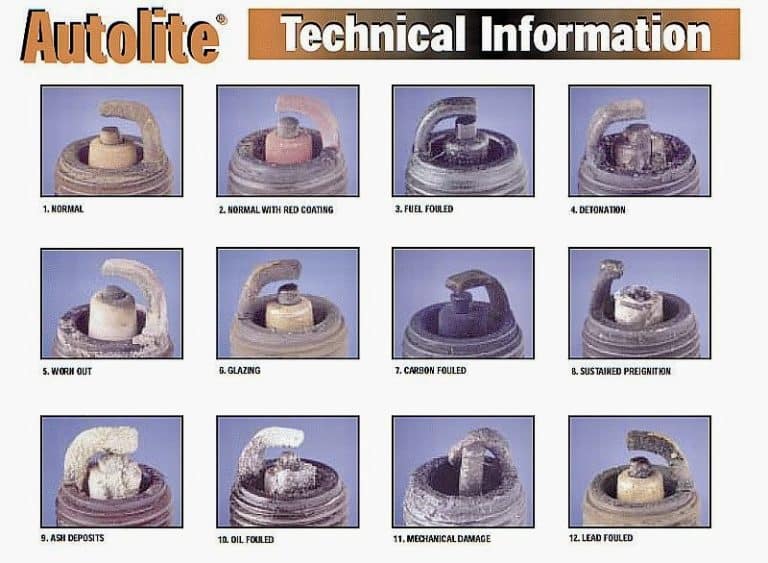

- Visual Inspection: This is the first and often most informative step. Remove the spark plugs and examine them carefully. Look for the following:

- Fouling: Deposits on the spark plug. Common types include:

- Carbon Fouling: Black, sooty deposits. Indicates a rich air/fuel mixture, weak spark, or excessive idling.

- Oil Fouling: Wet, oily deposits. Indicates oil entering the combustion chamber, often due to worn piston rings or valve stem seals.

- Fuel Fouling: Wet, fuel-smelling deposits. Indicates excessive fuel in the combustion chamber, often due to a leaky injector or faulty fuel pressure regulator.

- Lead Fouling: Reddish-brown deposits (rare now since leaded fuel is no longer widely used).

- Ash Fouling: Light-colored deposits. Indicates burning oil or coolant.

- Cracked or Broken Insulator: Indicates physical damage or excessive heat. A cracked insulator can cause misfires.

- Worn or Burned Electrodes: The electrodes should be relatively square and sharp. Rounded or excessively worn electrodes indicate age and need replacement. A burned electrode can indicate overheating or pre-ignition.

- Corrosion: Corrosion on the terminal or metal shell can impede electrical conductivity.

- Fouling: Deposits on the spark plug. Common types include:

- Spark Plug Tester: A spark plug tester allows you to visually check the spark produced by the plug outside the engine. It simulates the high-pressure environment of the combustion chamber. A weak or erratic spark indicates a faulty plug.

- Resistance Test (with a Multimeter): Using a multimeter set to measure resistance (Ohms), you can check the internal resistance of the spark plug. A significantly high or infinite resistance indicates a broken internal connection. Consult the spark plug manufacturer's specifications for acceptable resistance ranges (if available – this test is not always effective for all spark plug types).

- Compression Test: While not directly testing the spark plug, a compression test can help rule out other engine problems that can cause misfires, such as low compression in one or more cylinders. Low compression can prevent the air/fuel mixture from igniting properly, even with a good spark plug.

- Swapping Plugs: If you suspect a particular spark plug is causing a misfire, you can swap it with a plug from another cylinder. If the misfire moves to the new cylinder, it confirms that the original plug is the problem.

Pro Tip: When removing spark plugs, label them according to the cylinder they came from. This helps you track any cylinder-specific issues and correlate them with the appearance of the spark plugs.

Safety

Working with spark plugs involves handling high-voltage electricity and hot engine components. Always take the following safety precautions:

- Disconnect the Battery: Before working on the ignition system, disconnect the negative battery cable to prevent accidental shocks.

- Work on a Cool Engine: Allow the engine to cool completely before removing spark plugs to avoid burns.

- Use Proper Tools: Use a spark plug socket and torque wrench to avoid damaging the spark plugs or cylinder head.

- Wear Safety Glasses: Protect your eyes from debris.

High-voltage components of the ignition system can deliver a dangerous shock. Never touch spark plug wires or ignition coils while the engine is running.

Conclusion

Diagnosing bad spark plugs is a valuable skill for any car owner or DIY mechanic. By understanding the function of spark plugs, recognizing common failure symptoms, and following a systematic diagnostic process, you can save money, improve engine performance, and prevent more serious engine problems. Always prioritize safety and consult your vehicle's repair manual for specific instructions and torque specifications.

We have a comprehensive spark plug diagnostic diagram available for download. This diagram visually illustrates the troubleshooting steps, spark plug conditions, and potential causes, making the diagnostic process even easier.