How To Drive A Stick Shift Truck

So, you're ready to tackle mastering the stick shift in a truck? Good on you. While automatics dominate the roadways, knowing how to properly operate a manual transmission truck unlocks a new level of control, efficiency, and, frankly, driving satisfaction. This guide isn't just about the basics; we'll dive into the mechanics, techniques, and troubleshooting tips that even seasoned DIYers will find valuable. Consider this your detailed owner's manual for the art of driving a manual transmission truck.

Why Master the Manual Transmission Truck?

Understanding the intricacies of a manual transmission – often called a standard transmission – goes far beyond simply knowing how to get from point A to point B. Whether you're planning on overhauling your truck's transmission, diagnosing unusual noises, or simply wanting to become a more skilled driver, knowing how each component interacts is crucial. This knowledge will also be invaluable if you ever find yourself in a situation requiring you to drive a vehicle with a manual transmission.

Key Specs and Main Parts of a Manual Transmission

Before we get into the nitty-gritty, let's identify the major players involved in the manual transmission system. These components work in harmony to transfer power from the engine to the wheels. Here's a breakdown:

- Engine: The source of the power, measured in horsepower (hp) and torque (lb-ft).

- Clutch: This is what disengages the engine from the transmission, allowing you to shift gears. Key components are the clutch disc, pressure plate, and throw-out bearing.

- Flywheel: A heavy disc attached to the engine crankshaft, providing inertia and a surface for the clutch disc to engage.

- Transmission: The heart of the system, containing gears that multiply engine torque and provide different speed ratios. A typical truck might have 5 or 6 forward gears, plus reverse.

- Shift Linkage: The mechanical connection between the gear shift lever in the cabin and the transmission. Can be mechanical rods, cables, or a combination of both.

- Driveshaft: Connects the transmission to the rear axle (in rear-wheel-drive trucks) or transfer case (in four-wheel-drive trucks).

- Differential: Allows the wheels to rotate at different speeds when cornering.

- Axles: Transfer power from the differential to the wheels.

Truck-specific considerations often involve heavier-duty components throughout the drivetrain to handle increased loads and tougher driving conditions. This might mean a beefier clutch, a more robust transmission with wider gears, and a sturdier driveshaft.

Understanding the Symbols and Notations

While we don't have a physical diagram here, let's discuss how to interpret a typical transmission schematic if you were looking at one. Understanding these conventions makes interpreting the schematic much easier.

- Solid Lines: Generally represent mechanical connections, like shafts, rods, or cables.

- Dashed Lines: Often indicate fluid lines, like those for lubrication.

- Colors: Color coding is often specific to the diagram. A legend is crucial! Common examples:

- Red: High-pressure lines or power feeds.

- Blue: Lubrication or coolant lines.

- Black: Ground or return paths.

- Gear Symbols: Gears are usually represented by circles with teeth, with the number of teeth sometimes indicated to represent gear ratios.

- Clutch Symbol: Depicted with interlocking plates, indicating the engagement and disengagement mechanism.

- Bearing Symbols: Bearings are typically represented with circles.

How It Works: The Dance of Clutch and Gear

The magic of a manual transmission lies in its ability to vary the engine's torque output to the wheels, allowing for optimal performance in different driving conditions. Here's a simplified breakdown:

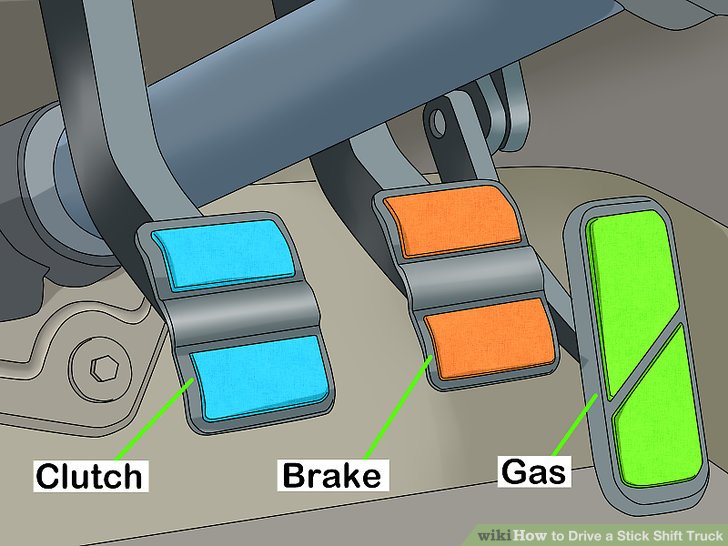

- Starting from a Stop: Press the clutch pedal to the floor. This disengages the engine from the transmission. Shift into first gear. Slowly release the clutch while gently pressing the accelerator pedal. This engages the engine, gradually transferring power to the wheels. The point where the clutch starts to engage is called the friction point. Finding this point is crucial for smooth starts.

- Shifting Up: Accelerate in the current gear. When the engine reaches the appropriate RPM (revolutions per minute), press the clutch pedal to the floor. Shift to the next higher gear. Release the clutch while simultaneously pressing the accelerator pedal. The timing and coordination of these actions are key to smooth upshifts.

- Shifting Down: When slowing down or approaching a hill, you may need to downshift to a lower gear for more torque. Press the clutch pedal to the floor. Shift to the desired lower gear. Release the clutch while blipping the throttle (briefly pressing the accelerator pedal) to match the engine speed to the transmission speed. This technique, called rev-matching, minimizes wear and tear on the clutch and transmission and results in smoother downshifts.

- Stopping: Press the clutch pedal to the floor to disengage the engine. Apply the brakes to slow down. As the truck comes to a stop, either shift into neutral or keep the clutch pedal depressed while in gear.

The gear ratio is crucial to understanding power delivery. A lower gear (e.g., first gear) provides a higher torque multiplication, allowing the truck to accelerate quickly or climb steep hills. A higher gear (e.g., fifth or sixth gear) provides a lower torque multiplication but allows for higher speeds and better fuel economy on the highway.

Real-World Use and Basic Troubleshooting

Even with a solid understanding of the mechanics, issues can arise. Here are some common problems and potential solutions:

- Difficulty Shifting: Could indicate a worn clutch, damaged synchros (components that synchronize gear speeds during shifting), or low transmission fluid. Check the clutch cable (if applicable) for proper adjustment. Consider a transmission fluid change. If it persists, you may need to rebuild the transmission.

- Clutch Slipping: The engine revs high, but the truck doesn't accelerate properly. This almost always points to a worn clutch disc. Replacement is necessary.

- Grinding Gears: Often occurs when shifting too quickly or without fully engaging the clutch. It can also indicate worn synchros. Avoid forcing the shift. Double-clutching (a more advanced technique involving engaging neutral between gears) can sometimes help mitigate the issue temporarily.

- Transmission Noise: Whining, humming, or clunking noises can indicate worn bearings, damaged gears, or low transmission fluid. A thorough inspection is required to pinpoint the source.

For complex issues, it's best to consult a qualified mechanic. A diagnostic scan can often pinpoint electrical or sensor-related problems that might be affecting transmission performance (particularly in newer trucks with electronic controls).

Safety Considerations

Working on a transmission involves inherent risks. Here are a few key safety points:

- Jacking and Supporting the Vehicle: Always use jack stands to support the vehicle before working underneath it. Never rely solely on the jack.

- Hot Components: The exhaust system and transmission can get extremely hot. Allow them to cool down completely before working on them.

- Sharp Edges: Many transmission components have sharp edges. Wear gloves to protect your hands.

- Fluid Spills: Transmission fluid can be slippery and hazardous. Clean up spills immediately.

- Proper Tools: Use the correct tools for the job. Trying to force a bolt with the wrong wrench can lead to damage and injury.

- The Clutch is a high-force spring loaded device. Use extreme caution when disassembling it. Eye protection is a must.

Remember, if you're not comfortable performing a particular task, it's always best to leave it to a professional. Your safety and the proper functioning of your truck are paramount.

Mastering the manual transmission in a truck takes practice, patience, and a good understanding of the underlying mechanics. With this knowledge, you'll be well on your way to becoming a skilled and confident driver.

Good luck, and happy shifting!