How To Drive Stick Shift Truck

So, you want to master the art of driving a stick shift truck? Excellent choice. While modern vehicles are increasingly automated, understanding and being able to operate a manual transmission truck unlocks a deeper connection with your vehicle, can be invaluable in certain situations (like driving a classic truck or off-roading), and opens doors to a greater understanding of automotive mechanics. This guide isn't just about getting from point A to point B; it's about understanding the mechanics that make it happen.

Purpose: Why Master the Manual?

Why bother learning to drive a stick shift truck in today's world? There are several compelling reasons:

- Enhanced Control: Manual transmissions give you more direct control over the engine's power output, crucial for situations like towing, off-roading, or navigating tricky terrain. You choose the gear, you control the RPMs.

- Mechanical Understanding: Learning the ins and outs of a manual transmission deepens your understanding of automotive mechanics. It's a fantastic stepping stone for DIY maintenance and repairs.

- Versatility: Knowing how to drive a stick shift can be useful if you ever need to operate older vehicles or trucks used in specific industries (construction, farming, etc.).

- Potentially Lower Cost: While not always the case, manual transmission trucks can sometimes be less expensive to purchase than their automatic counterparts (though finding them might be tricky).

Key Specs and Main Parts

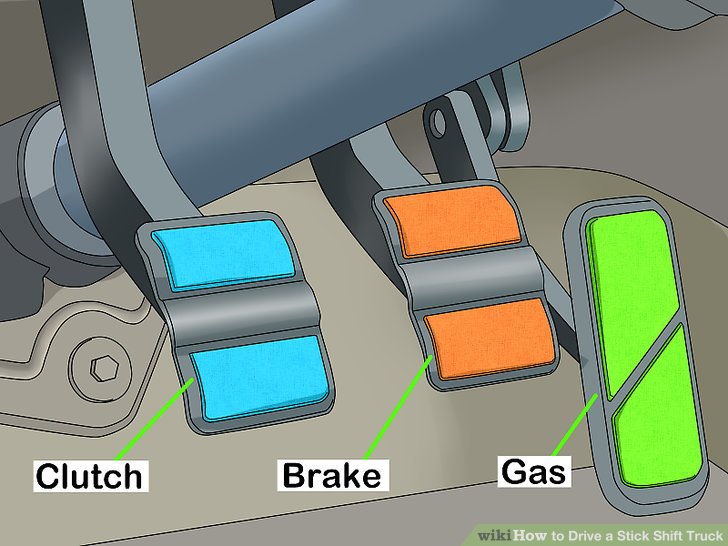

Let's break down the core components involved in driving a manual transmission truck:

- Engine: The heart of the operation. Provides the power.

- Clutch: This is your link to the engine. The clutch pedal disengages the engine from the transmission, allowing you to shift gears. It consists of the pressure plate, clutch disc, and throw-out bearing.

- Transmission: The gearbox containing gears of different ratios. Selects the appropriate gear for the desired speed and torque. Modern trucks often have 5, 6, or even more forward gears.

- Gear Shifter: The lever you use to select the desired gear. The shift pattern (H-pattern, etc.) varies depending on the truck.

- Driveshaft: Transmits power from the transmission to the differential.

- Differential: Distributes power to the wheels, allowing them to rotate at different speeds (essential for turning).

Understanding the basic relationships between these components is key. You control the engine's speed (RPM) with the gas pedal. The clutch allows you to disconnect the engine from the transmission. The gear shifter allows you to select the gear ratio to optimize for either torque or speed. This selected gear is then sent to the wheels.

How It Works: The Dance of Clutch, Gas, and Gear Shifter

Driving a stick shift truck is a coordinated dance of clutch, gas, and gear shifter. Here's a breakdown of the process:

- Starting: Ensure the truck is in neutral (the gear shifter is in the middle position where it doesn't engage any gear). Depress the clutch fully and turn the key. Once the engine starts, keep the clutch depressed.

- First Gear: Move the gear shifter into first gear. Slowly release the clutch while simultaneously applying a small amount of gas. The goal is to find the "friction point," where the engine starts to engage with the transmission. If done correctly, the truck will begin to move forward.

- Shifting Up: As the truck gains speed in first gear, release the gas pedal, depress the clutch fully, and move the gear shifter to second gear. Release the clutch while gently applying gas, similar to starting in first gear.

- Higher Gears: Repeat the process for higher gears (3rd, 4th, 5th, etc.) as your speed increases. Each shift requires a smooth and coordinated movement of the clutch, gas, and gear shifter.

- Downshifting: Downshifting is used to increase engine RPM for more power when climbing hills, passing other vehicles, or slowing down. Release the gas, depress the clutch, move the gear shifter to a lower gear, and release the clutch while "blipping" the gas pedal (briefly increasing the engine RPM) to match the engine speed to the transmission speed. This makes for smoother and less jarring downshifts.

- Stopping: To stop, gradually apply the brakes. As the truck slows down, depress the clutch fully to prevent the engine from stalling. Shift to neutral as you come to a complete stop.

Real-World Use: Basic Troubleshooting Tips

Here are a few common issues you might encounter and how to address them:

- Stalling: The most common issue for new stick shift drivers. Stalling usually happens when releasing the clutch too quickly or not giving enough gas. Practice finding the friction point and coordinating the clutch and gas.

- Jerky Shifts: This usually indicates a lack of coordination between the clutch, gas, and gear shifter. Practice smooth, deliberate movements. Blipping the throttle during downshifts can help.

- Grinding Gears: Gear grinding happens when the gears aren't fully engaged before the clutch is released. Ensure the clutch is fully depressed before shifting and that you're shifting into the correct gear. A worn clutch can also cause grinding.

- Clutch Slipping: If the engine RPMs increase but the truck doesn't accelerate accordingly, your clutch might be slipping. This could be due to a worn clutch disc or oil contamination.

If you suspect a major mechanical issue, don't hesitate to consult a qualified mechanic.

Safety: Risky Components

Working on a manual transmission can be dangerous if you don't take proper precautions. Here are some safety tips:

- Jack Stands: Always use jack stands when working under a vehicle. Never rely solely on a jack.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Gloves: Wear gloves to protect your hands from sharp edges and chemicals.

- Clutch Components: The clutch pressure plate is under significant spring tension. Improper disassembly can lead to serious injury. If you're not comfortable working with these components, seek professional help.

- Proper Tools: Use the correct tools for the job. Using the wrong tool can damage components and increase the risk of injury.

- Ventilation: Work in a well-ventilated area when using chemicals like brake cleaner or degreasers.

Important Note: The clutch system can be particularly dangerous due to the stored energy in the pressure plate. Only attempt repairs if you have the proper tools and knowledge. When in doubt, consult a professional.

Final Thoughts

Driving a stick shift truck is a rewarding skill. With practice and patience, you'll master the art of coordinating the clutch, gas, and gear shifter. And remember, always prioritize safety when working on your vehicle. This guide provides a solid foundation for understanding the fundamentals. Now, go practice and get that stick shift truck running smoothly!