How To Find Area Of Diamond

Alright, let's talk about finding the area of a diamond, or more accurately, a rhombus. Why are we covering this? Well, whether you're calculating the amount of material needed for a custom floor panel with diamond plating, figuring out the surface area for applying a rust preventative coating to a diamond-shaped component you fabricated, or just trying to understand geometry a little better for calculating complex angles in your suspension modifications, understanding the area of a rhombus is surprisingly useful in the DIY automotive world. We're going to break down the key concepts, formulas, and real-world applications in a way that makes sense for us mechanically-inclined folks.

Key Specs and Main Parts (of a Rhombus)

First, let's define some terms. A rhombus is a four-sided figure (a quadrilateral) where all four sides are of equal length. Think of it as a square that's been pushed over – all sides remain the same length, but the angles aren't necessarily 90 degrees. The 'parts' we care about when calculating the area are:

- Sides (s): The length of any one side of the rhombus. Since all sides are equal, they're all 's'.

- Diagonals (d1 and d2): These are the lines connecting opposite corners of the rhombus. A rhombus has two diagonals, and they're not necessarily equal in length. They bisect each other at right angles (90 degrees).

- Height (h): The perpendicular distance from one side to the opposite side. Imagine dropping a straight line from the top of the rhombus down to its base, forming a right angle.

- Angles (θ): The internal angles of the rhombus. Opposite angles are equal.

Formulas and How It Works

There are a few ways to calculate the area of a rhombus, depending on what information you have available. Let's cover the most common ones:

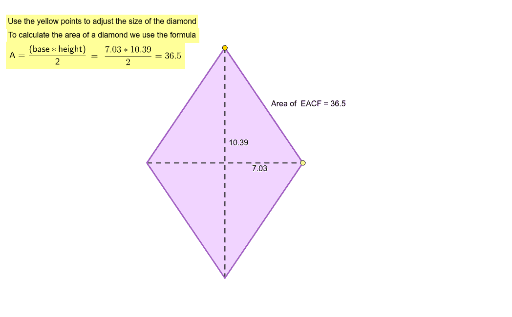

1. Using the Diagonals

This is generally the easiest and most direct method if you know the lengths of both diagonals. The formula is:

Area = (d1 * d2) / 2

Where:

- d1 = Length of the first diagonal

- d2 = Length of the second diagonal

Why this works: A rhombus can be divided into four congruent right triangles by its diagonals. Each triangle has a base of d1/2 and a height of d2/2. The area of one triangle is (1/2) * (d1/2) * (d2/2) = (d1 * d2) / 8. Since there are four triangles, the total area is 4 * (d1 * d2) / 8 = (d1 * d2) / 2.

Example: Let's say you're fabricating a diamond-shaped vent for your hood. You measure the diagonals and find they are 10 inches and 6 inches. Area = (10 * 6) / 2 = 30 square inches.

2. Using Base and Height

If you know the length of one side (which acts as the base) and the height of the rhombus, you can use this formula:

Area = base * height = s * h

Where:

- s = Length of a side (the base)

- h = Height (perpendicular distance to the opposite side)

Why this works: This is analogous to the area of a parallelogram. You can imagine cutting off a right triangle from one side of the rhombus and attaching it to the other side to form a rectangle with the same area. The area of the rectangle (and therefore the rhombus) is simply base times height.

Example: You're calculating the area of a diamond-shaped decal on your car. You measure the side (base) as 8 inches and the height as 5 inches. Area = 8 * 5 = 40 square inches.

3. Using Side and Angle

If you know the length of a side (s) and one of the angles (θ), you can use trigonometry to find the area:

Area = s2 * sin(θ)

Where:

- s = Length of a side

- θ = One of the angles (remember opposite angles are equal)

- sin(θ) = Sine of the angle θ

Why this works: The height (h) can be expressed as s * sin(θ). Substituting this into the base-height formula (Area = s * h), we get Area = s * (s * sin(θ)) = s2 * sin(θ).

Example: You're designing a custom diamond-shaped shift knob. You know the side length is 2 inches and one of the angles is 60 degrees. Area = 22 * sin(60°) = 4 * 0.866 ≈ 3.46 square inches.

Real-World Use – Basic Troubleshooting Tips

Here are some scenarios where knowing how to calculate the area of a rhombus can be handy:

- Material Calculations: When cutting diamond-shaped metal for custom body panels, floor plating, or decorative elements, knowing the area allows you to accurately estimate the amount of material needed, minimizing waste.

- Coating Application: Calculating the surface area helps determine the correct amount of paint, rust preventative, or other coatings required for optimal coverage.

- Design and Fabrication: When designing custom components, the area is a crucial factor for weight calculations, structural integrity, and overall aesthetics.

- Troubleshooting Fitment Issues: If you're installing diamond-shaped parts and experiencing fitment issues, accurately measuring and calculating the area can help identify discrepancies or design flaws.

Troubleshooting:

- Inaccurate Measurements: Double-check your measurements, especially for diagonals, as even a small error can significantly impact the calculated area.

- Units: Ensure all measurements are in the same units (e.g., inches, centimeters) before applying the formulas. The area will be in square inches, square centimeters, etc.

- Incorrect Angle: Make sure you're using the correct angle for the sin(θ) calculation. Use a protractor or angle finder for accurate measurements.

Safety

While calculating the area of a rhombus itself isn't inherently dangerous, the applications of this knowledge often involve working with tools and materials that can be. For example:

- Sharp Edges: When cutting metal for diamond-shaped parts, be mindful of sharp edges. Wear gloves and use appropriate cutting tools and techniques.

- Welding: If you're welding diamond-shaped components, use proper safety equipment, including a welding helmet, gloves, and protective clothing.

- Power Tools: When using power tools for cutting or shaping materials, always follow the manufacturer's safety instructions.

Specifically, when fabricating with metals, always ensure proper ventilation to avoid inhaling fumes. Also, remember to disconnect the battery from the vehicle before undertaking any electrical modifications or repairs. Working on your vehicle can be rewarding, but safety should always be your top priority.

And remember, precise measurements are key. A slight miscalculation can lead to wasted materials and frustration. Always double-check your work, and don't hesitate to ask for help from experienced mechanics or fabricators if you're unsure about something.

We've got a handy downloadable diagram summarizing these formulas and concepts. It's a great quick reference to keep in your garage or shop. Contact us and we will send you the file.