How To Find Tdc On Compression Stroke

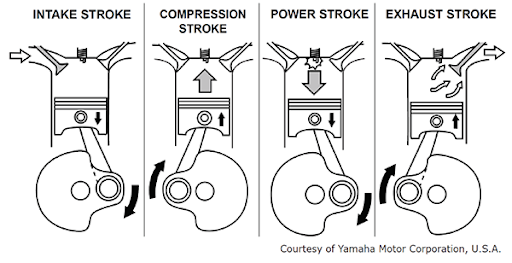

Finding Top Dead Center (TDC) on the compression stroke is a fundamental skill for anyone working on internal combustion engines. It's the process of locating the exact point where the piston in a cylinder is at the highest point of its travel *and* both valves are closed. This position is crucial for a variety of engine maintenance and repair tasks, including valve adjustments, distributor timing, and installing timing belts or chains.

Why Finding TDC on the Compression Stroke Matters

Accurately identifying TDC on the compression stroke is absolutely essential for several reasons. Incorrectly locating TDC can lead to significant engine problems, including:

- Incorrect Timing: If your timing is off, your engine will run poorly, if at all. This can lead to reduced power, poor fuel economy, and even engine damage.

- Valve Damage: Setting valve clearances at the wrong point in the engine's cycle can result in valves being held open when they should be closed, leading to valve and piston collision.

- Starting Issues: A misaligned distributor or incorrect timing can make starting the engine difficult or impossible.

- Engine Misfires: Improperly timed ignition events result in misfires, causing rough running and potential damage to catalytic converters.

- General Engine Performance: Even a slight deviation from true TDC can noticeably degrade engine performance.

Simply put, finding TDC correctly is not just a good idea, it's a requirement for proper engine function. Failing to do so can result in costly repairs and significant headaches.

How to Find TDC on the Compression Stroke: A Step-by-Step Guide

There are several methods for finding TDC on the compression stroke. Here's a breakdown of the most common and reliable techniques:

Method 1: The Finger/Compression Test

This is a simple and often effective method, especially useful for older engines or those with easily accessible spark plug holes.

- Disable the Ignition: Disconnect the ignition coil or other components to prevent the engine from starting. Safety first!

- Remove the Spark Plugs: Remove all spark plugs from the engine. This will make it easier to turn the engine over.

- Identify the Cylinder: Determine which cylinder you're working on. This is usually the cylinder where you need to set valve clearances or perform timing adjustments.

- Locate the Spark Plug Hole: Find the spark plug hole for the cylinder you've chosen.

- Place Your Finger/Thumb Over the Hole: Place your finger firmly over the spark plug hole, creating a seal.

- Crank the Engine Manually: Using a breaker bar on the crankshaft pulley (or by having someone briefly tap the starter), slowly turn the engine over *in its normal direction of rotation*.

- Feel for Compression: As the piston rises on the compression stroke, you will feel pressure building against your finger. This is the compression stroke.

- Continue Cranking: Keep cranking the engine until the pressure is at its highest. This is *close* to TDC.

- Verify TDC: Use a timing mark on the crankshaft pulley (see Method 2) to precisely align TDC.

Important Note: Be careful when cranking the engine manually. Use a proper breaker bar and apply steady pressure. Avoid sudden or jerky movements.

Method 2: Using Timing Marks

This method relies on the timing marks present on most engines. It's more precise than the finger method, but requires familiarity with your engine's specific markings.

- Disable the Ignition: Disconnect the ignition coil or other components to prevent the engine from starting. Safety is paramount!

- Locate the Timing Marks: Find the timing marks on your engine. These are typically located on the crankshaft pulley and a corresponding marker on the engine block or timing cover. Consult your engine's service manual for the exact location.

- Remove the Spark Plug: Remove the spark plug from the cylinder you are working on.

- Insert a TDC Finding Tool (Optional): A TDC finding tool, which is a long, slender rod, can be inserted into the spark plug hole to directly contact the piston. This tool allows you to visually see the piston's movement.

- Crank the Engine Manually: Using a breaker bar on the crankshaft pulley, slowly turn the engine over *in its normal direction of rotation*.

- Observe the Timing Marks: Watch the timing marks as you turn the engine. You're looking for the mark that indicates TDC (usually labeled as "0" or "TDC").

- Verify Compression: To confirm you are on the *compression stroke*, use the finger/compression test described above *simultaneously* while watching the timing marks. If you feel compression building as the timing marks align, you've found TDC on the compression stroke.

- Fine-Tune (if necessary): If you have a TDC finding tool, carefully rock the crankshaft back and forth around the TDC mark. Note the highest point the tool reaches. Split the difference between the points where the tool starts to descend. This is the most accurate TDC point.

Important Note: Timing marks can be difficult to see, especially on older engines. Clean the area thoroughly and use a timing light or bright flashlight to illuminate the marks.

Method 3: Using a Dial Indicator (For Maximum Accuracy)

This is the most accurate method, but requires a dial indicator and some mechanical skill. It's typically used for high-performance engines or when precise TDC location is critical.

- Disable the Ignition: Disconnect the ignition coil or other components to prevent the engine from starting. Safety is key!

- Remove the Spark Plug: Remove the spark plug from the cylinder you are working on.

- Install a Piston Stop: A piston stop prevents the piston from reaching the very top of its travel. This is necessary to find the exact center point. Screw the piston stop into the spark plug hole.

- Attach the Dial Indicator: Mount a dial indicator to the engine block so the indicator's probe contacts the piston (directly or via the spark plug hole).

- Find the Travel Limits: Rotate the engine clockwise until the piston contacts the piston stop. Record the dial indicator reading. Then, rotate the engine counter-clockwise until the piston contacts the stop on the other side. Record this reading.

- Calculate the Midpoint: The exact TDC point is halfway between the two dial indicator readings you recorded. Rotate the crankshaft until the dial indicator reads the calculated midpoint. This is true TDC.

- Verify Compression: As with the other methods, verify compression on the cylinder being measured to ensure you are on the compression stroke.

Important Note: Using a dial indicator requires precision and attention to detail. Ensure the indicator is properly mounted and calibrated. Consult a qualified mechanic if you're unsure about any step.

Choosing the Right Method

The best method for finding TDC depends on your skill level, the tools you have available, and the engine you're working on.

- Beginner: The finger/compression test is a good starting point for simple engine work.

- Intermediate: Using timing marks is a reliable method for most common engine tasks.

- Advanced: A dial indicator provides the highest level of accuracy and is recommended for performance applications.

Real-World Owner Experiences

Many car owners have shared their experiences finding TDC. Some common challenges include:

- Difficulty Seeing Timing Marks: "I struggled to see the timing marks on my old Ford pickup. I ended up cleaning them with a wire brush and using a bright light to make them visible." - John, Ford Truck Owner

- Confusing TDC with Exhaust Stroke: "I initially mistook the exhaust stroke for the compression stroke. I realized my mistake when I didn't feel any pressure building when I covered the spark plug hole." - Sarah, Honda Civic Owner

- Stripped Spark Plug Threads: "I was too aggressive when tightening the TDC finding tool, and I stripped the spark plug threads. I had to helicoil them, which was a major pain." - Michael, Motorcycle Enthusiast

These experiences highlight the importance of carefulness, patience, and having the right tools for the job.

Frequently Asked Questions (FAQs)

Q: What happens if I get TDC wrong?

A: Incorrect TDC can lead to poor engine performance, starting problems, valve damage, and other serious issues. It's crucial to get it right.

Q: Can I find TDC with the engine running?

A: No. You must disable the ignition and crank the engine manually.

Q: Do I need to remove all the spark plugs?

A: Removing all spark plugs makes it easier to turn the engine over, but you technically only *need* to remove the spark plug from the cylinder you're working on.

Q: What is a piston stop and why is it used?

A: A piston stop is a tool that prevents the piston from reaching the very top of its travel. It's used with a dial indicator to accurately find TDC by measuring the distance between two points where the piston contacts the stop.

Q: Where can I find my engine's timing marks?

A: Consult your engine's service manual for the exact location of the timing marks. They're typically located on the crankshaft pulley and a corresponding marker on the engine block or timing cover.

Q: What tools do I need to find TDC?

A: Depending on the method you choose, you may need a breaker bar, socket set, spark plug socket, TDC finding tool, dial indicator, piston stop, and your engine's service manual.

Finding TDC on the compression stroke is a vital skill for any engine enthusiast. By understanding the process and choosing the right method, you can ensure accurate timing and optimal engine performance. Remember to always prioritize safety and consult your engine's service manual for specific instructions.