How To Fix A Bad Alternator

So, your alternator’s acting up? Don't worry, even though it's a vital component, fixing a bad alternator is a task many experienced DIYers can tackle. This guide will walk you through understanding your alternator, diagnosing common issues, and, if you're up to it, even replacing it yourself. Think of this as your comprehensive field manual for all things alternator-related.

Understanding Your Alternator: The Heart of Your Car's Electrical System

The alternator isn't just some spinning doohickey under the hood; it's the cornerstone of your car's electrical charging system. Without it, your battery would quickly drain, leaving you stranded. This guide, and the accompanying diagram (which you can download at the end), is essential for understanding how your alternator works, diagnosing its problems, and performing necessary repairs or replacements. Knowing the parts and their functions allows you to troubleshoot electrical issues and potentially save a significant amount of money on garage bills.

Key Specs and Main Parts

Before we dive deep, let's establish the basic specifications and components:

- Voltage: Most automotive alternators operate at 12-14.8 volts DC. This range is crucial for charging the battery and powering all electrical components.

- Amperage: The amperage rating indicates the alternator's output capacity, usually ranging from 60 to 150 amps or more, depending on the vehicle's electrical load. Higher loads (like aftermarket audio systems or heavy-duty accessories) require alternators with higher amperage ratings.

The main parts you'll encounter are:

- Rotor (Armature): The rotating part with a coil of wire that generates the magnetic field. This is driven by the engine through a belt.

- Stator: The stationary part with windings where the electricity is induced. It surrounds the rotor.

- Rectifier (Diode Bridge): Converts the AC voltage generated by the stator into DC voltage suitable for the vehicle's electrical system. Diodes are one-way electrical valves.

- Voltage Regulator: Controls the alternator's output voltage to prevent overcharging the battery and damaging electrical components. Newer alternators often have the regulator built in.

- Brushes: Conduct electricity to the rotor's field windings. These wear down over time.

- Slip Rings: Smooth metal rings on the rotor that the brushes contact.

- Pulley: Connected to the engine via a belt, driving the rotor.

Decoding the Diagram: Lines, Colors, and Icons

The diagram we provide is a schematic representation of a typical alternator circuit. Here's a breakdown of what the various elements mean:

- Solid Lines: Represent wires carrying electrical current.

- Dashed Lines: Typically indicate mechanical connections, such as the belt driving the pulley.

- Colors: Wires are often color-coded (e.g., red for positive, black for ground). These color codes can vary by manufacturer, so always double-check your vehicle's wiring diagram.

- Icons: Standard electrical symbols are used to represent components. For example:

- Diode: A triangle pointing towards a line.

- Resistor: A zig-zag line.

- Capacitor: Two parallel lines.

- Ground: A downward pointing triangle or a series of lines decreasing in length.

Understanding these symbols is essential for tracing the circuit and identifying potential points of failure. The diagram also shows how the alternator connects to the battery, voltage regulator, and other components in the electrical system.

How It Works: From Mechanical Energy to Electrical Power

The alternator's job is to convert mechanical energy (from the engine) into electrical energy. Here's the process:

- The engine turns the alternator's pulley, which rotates the rotor.

- The rotor, powered by current fed through the brushes to the slip rings, creates a magnetic field.

- As the rotor spins, its magnetic field cuts across the stator windings. This induces an alternating current (AC) in the stator windings.

- The AC voltage from the stator is fed into the rectifier, which is essentially a bridge of diodes. These diodes only allow current to flow in one direction, converting the AC voltage to a direct current (DC) voltage.

- The DC voltage is then regulated by the voltage regulator, which ensures a constant output voltage (typically around 13.5-14.5 volts) to charge the battery and power the car's electrical system. The voltage regulator dynamically adjusts the current flowing through the rotor windings to maintain the correct output voltage.

Real-World Use: Troubleshooting Tips

Here are some common symptoms of a failing alternator and how to troubleshoot them:

- Dimming Headlights or Interior Lights: Indicates insufficient voltage. Check the battery voltage with a multimeter while the engine is running. It should be between 13.5 and 14.5 volts. If it's lower, the alternator might be failing.

- Battery Light On: This is a warning sign that the charging system is not functioning correctly. Don't ignore it!

- Dead Battery: A failing alternator might not be charging the battery properly, leading to a dead battery. However, a dead battery can also be caused by other issues, so rule those out first (e.g., leaving lights on).

- Strange Noises: Whining, grinding, or squealing noises coming from the alternator area can indicate worn bearings, a damaged pulley, or a loose belt.

- Burning Smell: A burning smell can indicate an overheating alternator, possibly due to a short circuit or a failing rectifier.

Here’s a basic troubleshooting procedure:

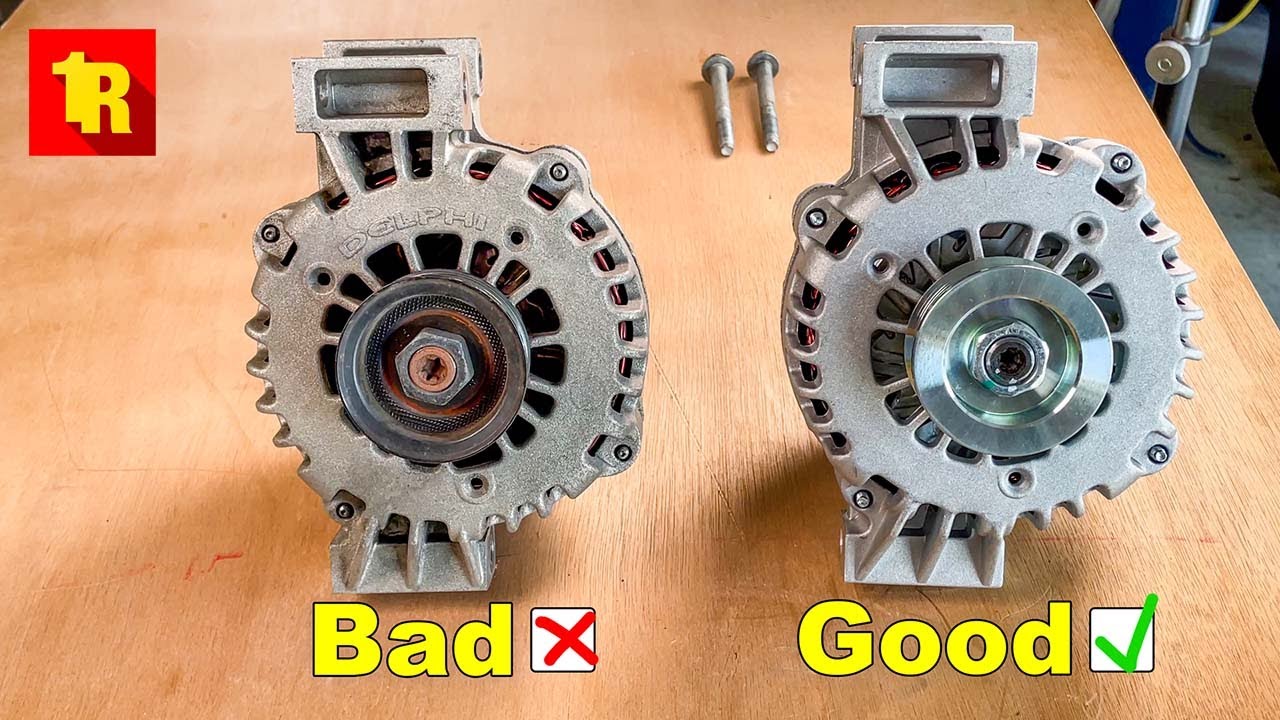

- Visual Inspection: Check the alternator belt for cracks, wear, or looseness. Ensure the connections to the alternator are clean and tight.

- Battery Voltage Test: Use a multimeter to check the battery voltage with the engine off (should be around 12.6 volts) and with the engine running (should be between 13.5 and 14.5 volts).

- Load Test: Have a professional perform a load test on the alternator to determine its output capacity under load. Most auto parts stores will do this for free.

Safety First: Handling Risky Components

Working on your car's electrical system can be dangerous if you're not careful. Here's what to watch out for:

- Battery: Always disconnect the negative battery terminal before working on any electrical component. This prevents accidental short circuits.

- High Voltage: Although the alternator operates at a relatively low voltage, it can still deliver a significant amount of current. Avoid touching any exposed wires or terminals while the engine is running.

- Moving Parts: Be extremely careful around the alternator belt and pulley while the engine is running. Keep your hands and tools clear.

The rectifier diodes are also susceptible to damage from static electricity. When handling a replacement rectifier, make sure to ground yourself to prevent static discharge.

Replacing an alternator is a task many competent DIYers can undertake. However, if you're uncomfortable working with electrical systems, it's always best to consult a qualified mechanic.

Ready to dive deeper? You can download the complete alternator circuit diagram HERE. This diagram provides a detailed schematic of the alternator's internal components and its connections to the rest of the vehicle's electrical system. Good luck, and happy wrenching!