How To Fix A Leaking Rack And Pinion

The dreaded power steering whine… followed by the telltale signs of fluid loss: a puddle under your car and a disconcerting lack of assistance when wrestling the steering wheel. Chances are, your rack and pinion is leaking. While a trip to a professional is always a valid option, understanding the underlying cause and exploring potential fixes can save you money and empower you with valuable automotive knowledge. This article dives deep into the anatomy of a leaking rack and pinion, exploring the common causes, diagnostic steps, and potential repair solutions.

The Leaky Faucet Analogy: Understanding the Problem

Imagine a leaky faucet. Water (in our case, power steering fluid) is under pressure, constantly trying to escape. The faucet’s seal is designed to contain this pressure. When the seal deteriorates, the water finds a path of least resistance and leaks out. A rack and pinion system operates on the same principle. High-pressure power steering fluid circulates within the rack, assisting your steering efforts. Internal seals are crucial for maintaining this pressure. Over time, these seals can degrade due to age, heat, contamination, or simply wear and tear, leading to leaks. Diagnosing a rack and pinion leak involves pinpointing where these seals have failed.

How the Rack and Pinion System Works: A Mechanical Deep Dive

The Basic Components

At its core, the rack and pinion system transforms the rotational motion of the steering wheel into the linear motion that steers the wheels. Here’s a breakdown of the key components:

- Pinion Gear: This is a small gear connected to the steering column. When you turn the steering wheel, you rotate the pinion gear.

- Rack: This is a long, toothed bar. The pinion gear meshes with the teeth on the rack. As the pinion rotates, it forces the rack to move linearly, either left or right.

- Hydraulic Cylinder (Power Steering Systems): This cylinder contains a piston connected to the rack. Power steering fluid, under pressure, acts on this piston to assist the rack's movement, reducing the effort required to steer the car.

- Rotary Valve: This valve, located near the pinion gear, directs the high-pressure fluid to either side of the hydraulic cylinder based on the steering wheel's direction.

- Seals and O-rings: Numerous seals are present throughout the system to prevent fluid leaks, especially at the rack ends, pinion shaft, and hydraulic cylinder.

- Tie Rods: These connect the rack to the steering knuckles, which in turn control the movement of the wheels.

The Mechanics in Action

When you turn the steering wheel, the pinion gear rotates. This rotation forces the rack to move linearly. In a power steering system, the rotary valve senses the direction of the steering input and directs high-pressure fluid to one side of the hydraulic cylinder. This fluid pressure assists the rack's movement, making steering easier. The tie rods then transmit this linear motion to the steering knuckles, turning the wheels. When a seal fails, the high-pressure fluid escapes, reducing the steering assist and causing the leak. The location of the leak often indicates the failed seal. Leaks near the tie rods usually point to worn rack end seals, while leaks near the pinion shaft suggest a problem with the pinion seal.

Diagnosing the Leak: A Step-by-Step Approach

- Identify the Fluid: Power steering fluid is typically red or amber in color and has a distinct odor. Differentiate it from engine oil or coolant.

- Locate the Leak: Carefully inspect the rack and pinion assembly. Look for signs of wetness, dripping fluid, or residue. Pay close attention to the rack ends (near the tie rods), the pinion shaft, and any hoses connected to the system.

- Check the Hoses and Connections: Sometimes, the leak isn't from the rack itself but from a loose hose or a damaged hose connection. Tighten clamps and inspect hoses for cracks or wear.

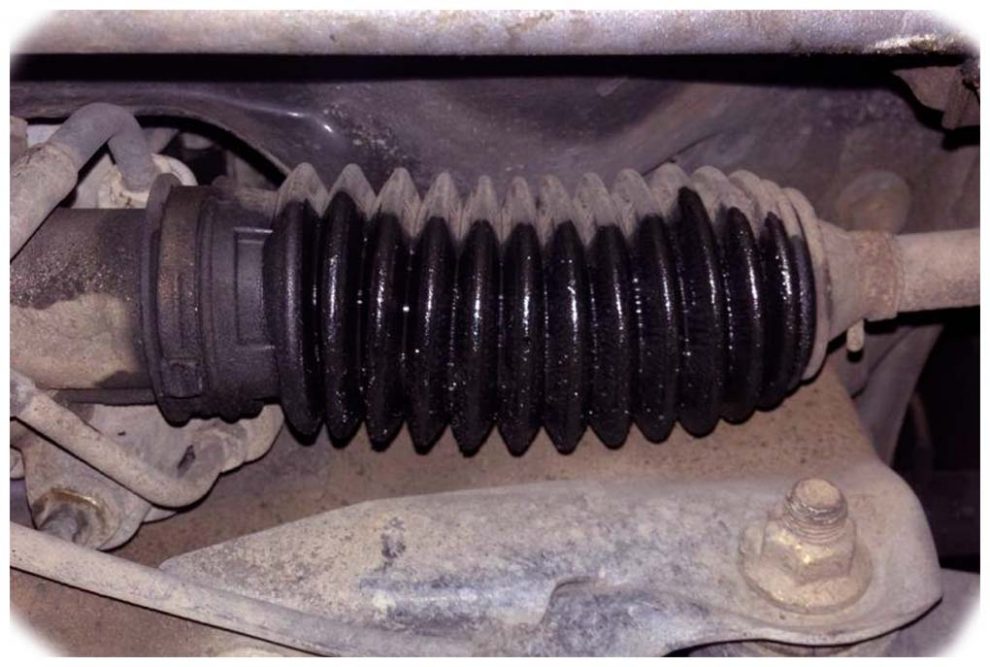

- Inspect the Dust Boots: Check the condition of the dust boots that protect the rack ends. Tears or damage to these boots can allow debris to enter the system, accelerating seal wear. If the boots are filled with fluid, it's a strong indication of a leaking rack end seal.

- Check the Power Steering Fluid Level: Low fluid levels are a telltale sign of a leak. Top up the fluid and monitor the level over time to gauge the severity of the leak.

Repair Options: Weighing the Pros and Cons

Once you've confirmed the leak, you have several repair options, each with its own advantages and disadvantages:

1. Power Steering Stop Leak Additives

- Pros: Least expensive, easiest to apply.

- Cons: Temporary fix, may not work for severe leaks, can potentially damage other components in the system, often just swells the seals temporarily.

- Use Cases: Suitable for very minor leaks as a temporary measure to buy time. Not recommended for long-term solutions.

Technical Note: These additives typically contain chemicals that swell the rubber seals, temporarily sealing the leak. However, this swelling can weaken the seals over time and potentially cause other problems in the system, such as clogged valves.

2. Replacing the Seals

- Pros: More cost-effective than replacing the entire rack, addresses the root cause of the problem.

- Cons: Requires specialized tools and expertise, can be time-consuming, not always successful if the rack itself is damaged.

- Use Cases: Ideal for experienced DIYers or mechanics who are comfortable disassembling and rebuilding the rack.

Technical Note: Replacing the seals involves disassembling the rack and pinion, carefully removing the old seals, and installing new ones. This requires precision and attention to detail to ensure proper sealing and avoid damaging other components. A seal kit is often available for specific models, providing all the necessary seals and O-rings.

3. Replacing the Entire Rack and Pinion Assembly

- Pros: Most reliable solution, ensures all components are in good working order, relatively straightforward installation (compared to seal replacement).

- Cons: Most expensive option.

- Use Cases: Recommended for severe leaks, damaged racks, or when the seals are inaccessible or difficult to replace. Also a good option for less experienced DIYers who prefer a simpler installation process.

Technical Note: Replacing the rack and pinion assembly involves disconnecting the tie rods, hoses, and steering column, removing the old rack, and installing the new one. After installation, it's essential to bleed the power steering system to remove air bubbles and ensure proper operation. An alignment is also highly recommended.

4. Rebuilt or Remanufactured Rack and Pinion

- Pros: More affordable than a new rack, environmentally friendly.

- Cons: Quality can vary depending on the rebuilder, potential for early failure if not properly rebuilt.

- Use Cases: A good compromise between cost and reliability. Choose a reputable rebuilder with a warranty.

Technical Note: Remanufactured racks are typically disassembled, cleaned, inspected, and rebuilt with new seals and worn components. They are often tested to ensure they meet OEM specifications.

Manufacturer Examples and Common Issues

Different manufacturers have different rack and pinion designs, and some are more prone to leaks than others. For example:

- Honda and Acura: Known for pinion seal leaks, especially in older models.

- Ford: Rack end seal leaks are common, particularly in trucks and SUVs.

- GM: Both pinion and rack end seals can fail, often due to corrosion or contamination.

Understanding the common issues associated with your specific vehicle can help you diagnose the problem more accurately and choose the appropriate repair solution.

Real-World Insights and Recommendations

Based on real-world experience, here are some additional insights and recommendations:

- Prevention is Key: Regularly check your power steering fluid level and condition. Replace the fluid according to the manufacturer's recommendations to prevent seal degradation.

- Don't Ignore Minor Leaks: Even small leaks can worsen over time, leading to more significant problems and costly repairs. Address them promptly.

- Choose Quality Parts: When replacing seals or the entire rack, opt for high-quality parts from reputable manufacturers. Avoid cheap, generic parts, as they may not last as long.

- Proper Bleeding is Crucial: After any repair involving the power steering system, ensure you bleed the system properly to remove air bubbles. This will prevent noise, poor steering performance, and potential damage to the pump.

- Consider Professional Assistance: If you're not comfortable working on your car's steering system, seek professional help. Steering is a critical safety system, and improper repairs can have serious consequences.

- Alignment After Replacement: Replacing the rack and pinion will affect the alignment. Have a professional alignment performed immediately after installation.

Fixing a leaking rack and pinion can seem daunting, but with a basic understanding of the system and a careful approach, it can be a manageable task. Whether you choose to replace the seals, the entire rack, or seek professional assistance, remember that addressing the problem promptly and using quality parts will ensure safe and reliable steering for years to come.