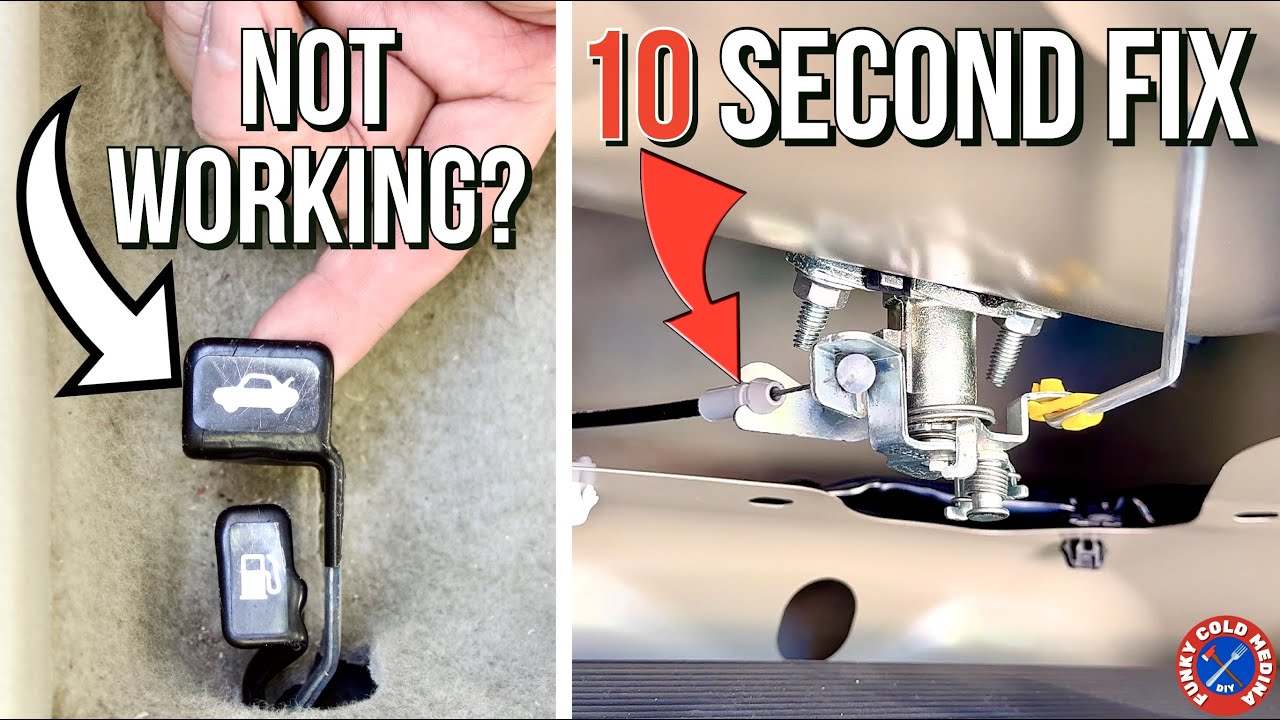

How To Fix A Trunk Latch

Let's talk about trunk latches. A malfunctioning trunk latch can be a real pain. You might find your trunk won't stay closed, or worse, it won't open! Understanding how the system works and knowing the common failure points empowers you to diagnose and often fix the problem yourself. This guide provides a technical overview of the trunk latch mechanism, troubleshooting steps, and essential safety considerations.

Understanding the Trunk Latch System

The purpose of understanding the trunk latch system is multifaceted. Primarily, it allows for efficient and cost-effective repairs. Instead of blindly replacing parts, you can pinpoint the issue, saving time and money. Secondly, it provides a deeper understanding of your vehicle's mechanics, fostering better maintenance habits. Finally, it enables you to perform modifications and upgrades with greater confidence.

Key Specs and Main Parts

A typical trunk latch system consists of several key components:

- Latch Assembly: The core mechanism that physically secures the trunk lid to the vehicle body. It usually contains a spring-loaded pawl (a pivoting arm) that engages with the striker.

- Striker (or Striker Bolt): A metal loop or bar mounted on the vehicle body that the latch mechanism engages with. Its position is crucial for proper latch operation.

- Actuator (Solenoid or Motor): Electrically operated device that releases the latch. Modern vehicles often use solenoids, while some older or high-end models might employ small electric motors.

- Release Mechanism: This can be a manual lever inside the vehicle, a button on the trunk lid, or an electronic signal from the key fob.

- Wiring Harness: Provides the electrical connection between the release mechanism, the actuator, and the vehicle's electrical system.

- Trunk Lid Sensor/Switch: Detects whether the trunk is open or closed. This information is often used to control the trunk light and trigger warning lights on the dashboard.

How It Works

The trunk latch system operates on a relatively simple principle. When the trunk lid is closed, the latch assembly engages with the striker. A spring mechanism within the latch keeps the pawl engaged, preventing the trunk from opening. To release the trunk, one of two things usually happens:

- Manual Release: Activating the manual release lever pulls a cable connected to the latch assembly, disengaging the pawl from the striker.

- Electrical Release: Pressing the trunk release button on the key fob or dashboard sends an electrical signal to the actuator (solenoid or motor). The actuator then pulls a lever or cable that disengages the pawl from the striker.

The trunk lid sensor/switch monitors the trunk's position. When the trunk is open, the sensor completes a circuit, illuminating the trunk light. When the trunk is closed, the circuit is broken, turning off the light. This sensor can also communicate with the car's computer to trigger warning lights on the dashboard if the trunk is ajar while driving.

Troubleshooting Your Trunk Latch

Here's a breakdown of common issues and how to diagnose them:

- Trunk Won't Open:

- Check the Fuse: A blown fuse is the simplest and most common cause. Consult your owner's manual to locate the fuse for the trunk release circuit.

- Test the Actuator: Use a multimeter to check if the actuator is receiving power when the release button is pressed. If it's not, the problem lies in the wiring or the release mechanism itself. If it is receiving power, the actuator may be faulty and require replacement.

- Inspect the Linkage: Examine the cables and levers connecting the release mechanism to the latch assembly. Ensure they are not broken, disconnected, or binding.

- Lubricate the Latch: Sometimes, a sticky latch is all that's preventing the trunk from opening. Apply a liberal amount of lubricant, such as WD-40 or lithium grease, to the latch mechanism and striker.

- Trunk Won't Stay Closed:

- Adjust the Striker: The striker may be misaligned, preventing the latch from engaging properly. Loosen the striker bolts and adjust its position until the latch engages securely.

- Inspect the Latch Mechanism: Look for signs of damage or wear in the latch assembly. Check the spring mechanism for proper tension. A worn or damaged latch may need replacement.

- Check for Obstructions: Ensure there are no objects obstructing the trunk lid from closing completely.

- Trunk Light Stays On:

- Check the Trunk Lid Sensor/Switch: This sensor is often located near the latch. Make sure it is not damaged, dirty, or stuck in the "open" position. Clean the sensor or replace it if necessary.

- Wiring Issue: A short circuit in the wiring harness could cause the trunk light to stay on. Inspect the wiring for any signs of damage or corrosion.

Symbols and Conventions in Wiring Diagrams

Understanding the symbols used in wiring diagrams is crucial for diagnosing electrical problems. Here are some common symbols:

- Solid Lines: Represent wires. The thickness of the line may indicate the wire gauge (thickness).

- Dashed Lines: Often indicate shielded cables or ground connections.

- Circles: Can represent various components, such as lights, motors, or sensors. The specific component is usually indicated by a label inside the circle.

- Squares or Rectangles: Typically represent switches, relays, or integrated circuits (ICs).

- Resistor Symbol (Zig-zag line): Represents a resistor, which limits the flow of current in a circuit.

- Capacitor Symbol (Two parallel lines): Represents a capacitor, which stores electrical energy.

- Ground Symbol (Downward pointing triangle): Indicates a connection to the vehicle's chassis ground.

- Color Codes: Wires are often color-coded to aid in identification. Common color codes include BLK (Black), RED (Red), BLU (Blue), GRN (Green), YEL (Yellow), and WHT (White).

Note: Different manufacturers may use slightly different symbols, so always refer to the specific wiring diagram for your vehicle.

Safety Precautions

Working on electrical systems involves inherent risks. Here are some crucial safety precautions:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative battery terminal to prevent accidental short circuits or electric shock.

- Use Proper Tools: Use insulated tools designed for automotive electrical work.

- Be Careful with Wiring: Handle wiring harnesses carefully to avoid damaging the wires or connectors.

- Do Not Overload Circuits: When testing circuits, avoid overloading them with excessive current, as this can damage components or cause a fire.

- High Voltage: Be aware that some components, such as those related to the anti-theft system, might retain some residual charge even after the battery is disconnected. Treat these components with extreme caution.

Remember, if you are not comfortable working with electrical systems, it's always best to consult a qualified mechanic.

Real-World Use: Basic Troubleshooting Tips

Let's say your trunk stopped opening with the key fob. Here's a practical approach:

- Check the Key Fob Battery: Ensure the key fob battery is not depleted. A weak battery might not provide enough power to activate the actuator.

- Listen for the Actuator: When you press the trunk release button, listen for a clicking sound coming from the actuator. If you hear a click, the actuator is likely receiving power but may be faulty. If you don't hear anything, the problem could be a blown fuse or a wiring issue.

- Check the Fuse: Locate the fuse for the trunk release circuit in your owner's manual and inspect it for damage. Replace the fuse if necessary.

- Test the Actuator with a Multimeter: If the fuse is good, use a multimeter to check if the actuator is receiving voltage when the release button is pressed.

- Inspect the Wiring: Look for any signs of damage or corrosion in the wiring harness connecting the release button, the actuator, and the vehicle's electrical system.

By following these steps, you can systematically diagnose the problem and identify the faulty component.

We have a detailed trunk latch system diagram available for download, providing a visual reference for all the components and their connections. This diagram can be invaluable for troubleshooting and repair.