How To Fix Cylinder 6 Misfire

Chasing down a cylinder misfire can feel like playing automotive detective, especially when it's cylinder number six throwing the code. It’s not always a straightforward fix, but with a systematic approach and a good understanding of how your engine operates, you can usually diagnose and resolve the issue. So, your engine’s shaking, the "check engine" light is taunting you, and the OBD-II scanner is pointing its accusing finger at cylinder six. Where do you begin?

The Misfire Mystery: A Scenario

Imagine your engine as a well-orchestrated symphony. Each cylinder, a musician, plays its part in perfect harmony. The piston moves, compressing the air-fuel mixture, the spark ignites it, the resulting explosion drives the piston down, and the exhaust valves open, clearing the stage for the next cycle. Now, imagine the sixth musician is consistently playing out of tune. The entire performance suffers. This is what a misfire feels like – an interruption in the smooth power delivery of your engine. It's a single cylinder not contributing its fair share to the overall combustion process. The Engine Control Unit (ECU) detects this irregularity through crankshaft speed variations and flags the misfire, often triggering a P0306 code.

Decoding the Mechanics: How It Works

Before diving into specific fixes, let's understand the fundamental processes occurring within cylinder six. A typical four-stroke engine cycle involves four distinct phases:

- Intake: The intake valve opens, and the piston moves down, drawing in a mixture of air and fuel.

- Compression: Both valves close, and the piston moves up, compressing the air-fuel mixture.

- Combustion: The spark plug ignites the compressed mixture, causing a controlled explosion that forces the piston down.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder.

A misfire occurs when any of these phases are disrupted. Specifically for cylinder six, potential culprits include:

- Ignition System: A faulty spark plug, ignition coil, or wiring can prevent the spark from igniting the air-fuel mixture.

- Fuel System: A clogged fuel injector can restrict fuel flow to the cylinder, resulting in a lean mixture that won't ignite properly.

- Compression Issues: Worn piston rings, damaged valves, or a blown head gasket can lead to reduced compression, making it difficult for the mixture to ignite.

- Vacuum Leaks: A vacuum leak near cylinder six can alter the air-fuel ratio, causing a misfire.

- Valve Train Problems: A bent valve, worn camshaft lobe, or stuck lifter can disrupt valve timing and cause a misfire.

- Engine Control Unit (ECU): In rare cases, the ECU itself can be the source of the problem, sending incorrect signals to the ignition or fuel systems.

Step-by-Step Troubleshooting

- Check the Spark Plug: This is often the easiest and cheapest first step. Remove the spark plug from cylinder six and inspect it. Look for signs of wear, damage, fouling (carbon buildup), or oil contamination. Compare it to a spark plug from a known good cylinder. Replace it if necessary. Even if it looks okay, consider swapping it with the spark plug from another cylinder (e.g., cylinder one) to see if the misfire moves. If the misfire code changes to P0301 (cylinder one misfire), you've confirmed the spark plug is the issue.

- Inspect the Ignition Coil: The ignition coil provides the high-voltage spark needed to ignite the air-fuel mixture. Test the coil using a multimeter to check its resistance. Compare the reading to the manufacturer's specifications. If the coil's resistance is out of range, replace it. Similar to the spark plug, you can also swap the coil with another cylinder to see if the misfire follows the coil.

- Evaluate the Fuel Injector: Fuel injectors can become clogged over time, restricting fuel flow. You can try using a fuel injector cleaner added to the fuel tank. However, for a suspected clogged injector on cylinder six, professional cleaning or replacement might be necessary. A mechanic can perform a fuel injector flow test to determine if the injector is delivering the correct amount of fuel. Listen to the injector with a stethoscope. You should hear a consistent clicking sound, indicating it's opening and closing. If the injector is silent or makes a weak sound, it may be faulty.

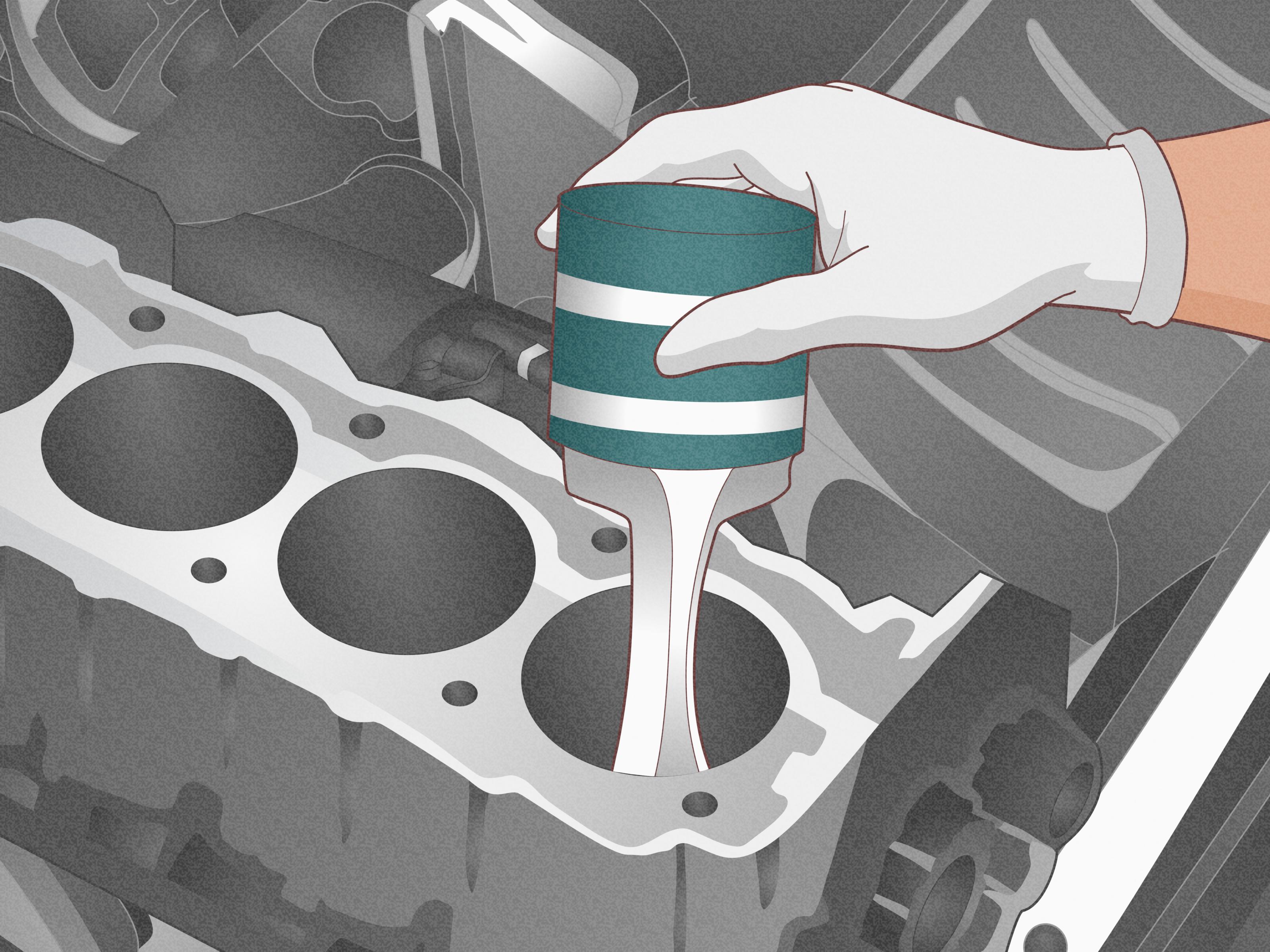

- Conduct a Compression Test: A compression test measures the pressure within each cylinder. Low compression in cylinder six indicates a problem with the piston rings, valves, or head gasket. Perform a dry compression test first. Then, if the compression is low, perform a wet compression test (add a small amount of oil to the cylinder). If the compression improves significantly with oil, it suggests worn piston rings. If the compression remains low, the problem is likely with the valves or head gasket.

- Check for Vacuum Leaks: Use a vacuum gauge or a can of carburetor cleaner to check for vacuum leaks around the intake manifold and vacuum hoses near cylinder six. Spray small amounts of carburetor cleaner around these areas. If the engine RPM increases, it indicates a vacuum leak in that area.

- Inspect Wiring and Connectors: Check the wiring and connectors leading to the spark plug, ignition coil, and fuel injector. Look for signs of damage, corrosion, or loose connections. Use dielectric grease to protect the connections from corrosion.

Pros/Cons of DIY vs. Professional Repair

DIY Advantages: Cost savings, increased understanding of your engine, sense of accomplishment. DIY Disadvantages: Requires specialized tools and knowledge, can be time-consuming, risk of further damage if done incorrectly.

Professional Advantages: Expertise and experience, access to advanced diagnostic equipment, warranty on repairs. Professional Disadvantages: Higher cost, dependence on the mechanic's skill and honesty.

Real-World Examples and Manufacturer Considerations

Misfires are common across various manufacturers, but some engines are more prone to specific issues. For example:

- BMW N54/N55 Engines: These engines are known for fuel injector issues, leading to misfires.

- Ford 4.6L/5.4L Engines: Spark plug issues and broken spark plug electrodes are common problems.

- GM LS Engines: Valve spring failures can cause misfires, especially in high-performance applications.

Understanding the common failure points for your specific engine can significantly streamline the diagnostic process. Consulting online forums and technical service bulletins (TSBs) can provide valuable insights.

Final Thoughts and Recommendations

Diagnosing a cylinder six misfire requires a systematic approach. Start with the simplest and most common causes, such as the spark plug and ignition coil, and then progress to more complex issues like compression problems or fuel injector failures. Remember to document your findings and take pictures along the way. If you're not comfortable performing these repairs yourself, consult a qualified mechanic. A proper diagnosis and repair will not only resolve the misfire but also prevent potential damage to other engine components. Regular maintenance, including spark plug replacement and fuel system cleaning, can help prevent future misfires.

Before committing to any repairs, consider using an OBD-II scanner that can display live engine data. Monitoring parameters like fuel trims, oxygen sensor readings, and misfire counts can provide valuable clues about the underlying cause of the misfire. Also, consider the age and mileage of your vehicle. If you're nearing the recommended service interval for certain components (e.g., spark plugs, fuel injectors), it might be prudent to replace them as part of the repair process. By taking a methodical approach and considering all the factors involved, you can successfully diagnose and fix a cylinder six misfire and get your engine running smoothly again.