How To Install A Clutch Slave Cylinder

Replacing a clutch slave cylinder can seem daunting, but with the right tools and a little patience, it's a task many DIY mechanics can tackle. This article provides a comprehensive guide on how to install a clutch slave cylinder, offering insights into why this component is crucial, how to select the correct replacement, and what to expect from the process. We'll also share real-world owner experiences and address frequently asked questions to ensure a smooth and successful installation.

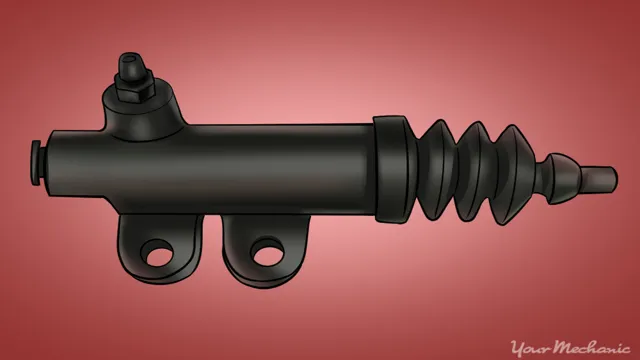

What is a Clutch Slave Cylinder and How Does it Work?

The clutch slave cylinder is a vital hydraulic component in your vehicle's clutch system. Its primary function is to engage and disengage the clutch, allowing you to smoothly shift gears. Think of it as a hydraulic actuator. When you press the clutch pedal, hydraulic pressure is generated in the master cylinder (located near the pedal). This pressure is then transmitted through a hydraulic line to the slave cylinder, which is typically mounted on the transmission housing near the clutch fork. The pressure forces the slave cylinder's pushrod to move, which, in turn, pushes on the clutch fork. The clutch fork pivots, disengaging the clutch disc from the flywheel and allowing you to change gears. Releasing the pedal reverses the process, re-engaging the clutch.

Why Clutch Slave Cylinder Replacement Matters

A malfunctioning or failing clutch slave cylinder can lead to a variety of problems that significantly impact your vehicle's performance and drivability. Here's why addressing issues with this component is crucial:

- Difficulty Shifting Gears: One of the most common symptoms of a failing slave cylinder is difficulty shifting gears. You may experience grinding, sticking, or an inability to get the car into gear, especially first gear or reverse.

- Clutch Pedal Issues: You might notice a spongy or soft clutch pedal feel. In severe cases, the pedal may even go all the way to the floor and stay there. This indicates a loss of hydraulic pressure within the system.

- Fluid Leaks: A leaking slave cylinder will result in a loss of brake fluid. This can lead to low hydraulic pressure and the symptoms mentioned above. You may notice brake fluid pooling near the slave cylinder or dripping from the transmission housing.

- Complete Clutch Failure: If the slave cylinder fails completely, you won't be able to disengage the clutch at all, rendering your vehicle undrivable. This can leave you stranded and require a tow.

- Damage to Other Components: Attempting to drive with a failing slave cylinder can put undue stress on other parts of the clutch system, such as the clutch disc, pressure plate, and even the transmission itself, leading to more costly repairs down the line.

Choosing the Right Replacement Clutch Slave Cylinder

Selecting the correct replacement clutch slave cylinder is paramount to ensure proper fitment and performance. Here's what to consider:

- Vehicle Make, Model, and Year: This is the most crucial information. Always refer to your vehicle's owner's manual or a reliable parts catalog to identify the correct part number. Different vehicles use different slave cylinder designs and sizes.

- OEM vs. Aftermarket: You have the option of choosing an Original Equipment Manufacturer (OEM) part or an aftermarket replacement. OEM parts are manufactured by the same company that made the original part for your vehicle, ensuring quality and compatibility. Aftermarket parts can be more affordable, but quality can vary. Choose reputable brands with positive reviews.

- Material: Slave cylinders are typically made from cast iron or aluminum. Aluminum is lighter and resists corrosion better, but cast iron can be more durable in some applications. Consider the environment your vehicle operates in (e.g., areas with road salt) when making your decision.

- Pre-Bleed vs. Non-Bleed: Some slave cylinders come pre-bled, meaning they are already filled with hydraulic fluid and don't require bleeding after installation. This can simplify the installation process. However, non-bled cylinders are generally less expensive. You'll need to bleed the system after installation using a bleed valve or manually.

- Warranty: Check the warranty offered by the manufacturer. A longer warranty typically indicates greater confidence in the product's quality and durability.

How to Install a Clutch Slave Cylinder: A Step-by-Step Guide

Important Safety Note: Always disconnect the negative battery cable before working on any electrical components of your vehicle. Wear safety glasses to protect your eyes from brake fluid. Work in a well-ventilated area. If you are not comfortable performing this repair, consult a qualified mechanic.

- Gather Your Tools and Materials: You will need:

- New clutch slave cylinder

- Wrench set

- Socket set

- Brake fluid (check your owner's manual for the correct type)

- Catch pan

- Jack and jack stands

- Wheel chocks

- Penetrating oil (optional, for rusty bolts)

- Rags or shop towels

- Prepare the Vehicle:

- Park the vehicle on a level surface.

- Engage the parking brake and chock the rear wheels.

- Loosen the lug nuts on the front wheels.

- Jack up the front of the vehicle and securely support it with jack stands.

- Remove the front wheels for easier access (optional).

- Locate the Clutch Slave Cylinder: The slave cylinder is typically mounted on the transmission housing, near the clutch fork. It will be connected to the hydraulic line.

- Disconnect the Hydraulic Line:

- Place a catch pan underneath the slave cylinder to collect any spilled brake fluid.

- Carefully disconnect the hydraulic line from the slave cylinder. You may need to use a line wrench to avoid damaging the fittings.

- If the fitting is corroded, apply penetrating oil and let it soak for a few minutes before attempting to loosen it.

- Plug the end of the hydraulic line to prevent fluid from continuing to drain. A small rubber cap or even a clean bolt can be used.

- Remove the Old Slave Cylinder:

- Remove the bolts securing the slave cylinder to the transmission housing.

- Carefully remove the old slave cylinder. You may need to wiggle it slightly to free it from the mounting bracket.

- Install the New Slave Cylinder:

- Inspect the mounting surface on the transmission housing and clean it if necessary.

- Apply a small amount of grease to the pushrod of the new slave cylinder.

- Position the new slave cylinder in place and secure it with the mounting bolts. Tighten the bolts to the manufacturer's specified torque (if available; otherwise, snug but not overtightened).

- Connect the Hydraulic Line:

- Remove the plug from the hydraulic line.

- Carefully connect the hydraulic line to the new slave cylinder. Tighten the fitting securely, but do not overtighten.

- Bleed the Clutch System: This is a critical step.

- Locate the bleed screw on the slave cylinder.

- Attach a clear hose to the bleed screw and submerge the other end in a container partially filled with brake fluid.

- Have an assistant slowly depress and release the clutch pedal several times.

- Open the bleed screw while the assistant is depressing the clutch pedal. Air and fluid will be expelled into the container.

- Close the bleed screw before the assistant releases the clutch pedal.

- Repeat this process until no more air bubbles are visible in the fluid flowing through the hose.

- Check the brake fluid level in the master cylinder reservoir and top it off as needed.

- Test the Clutch:

- Start the engine and test the clutch pedal. It should feel firm and responsive.

- Shift through all the gears to ensure the clutch is engaging and disengaging properly.

- If you still experience difficulty shifting, repeat the bleeding process.

- Reassemble and Final Checks:

- Reinstall the front wheels (if removed) and tighten the lug nuts to the manufacturer's specified torque.

- Lower the vehicle from the jack stands.

- Double-check the brake fluid level in the master cylinder reservoir.

- Dispose of the old slave cylinder and any spilled brake fluid properly.

Real-World Owner Experiences

Many car owners have successfully replaced their clutch slave cylinders. Here are a few common themes from their experiences:

- Bleeding is Key: The most common challenge is properly bleeding the clutch system. Air trapped in the lines can cause a spongy pedal and difficulty shifting. Some owners have found that using a vacuum bleeder can make the process easier.

- Tight Spaces: Access to the slave cylinder can be tight in some vehicles. Using the correct tools and a flexible extension can help.

- Corrosion: Rust and corrosion can make it difficult to remove the old slave cylinder and disconnect the hydraulic line. Penetrating oil is your friend!

- Quality Parts: Investing in a high-quality replacement slave cylinder is worth the extra cost. Cheaper parts may fail prematurely.

Frequently Asked Questions (FAQs)

Q: How much does it cost to have a mechanic replace a clutch slave cylinder?

A: The cost can vary depending on the vehicle and the mechanic's labor rate, but you can typically expect to pay between $150 and $400 for parts and labor.

Q: How long does it take to replace a clutch slave cylinder?

A: For a DIYer with some experience, the job can usually be completed in 1-3 hours.

Q: Can I drive my car with a bad clutch slave cylinder?

A: It is not recommended to drive your car with a bad clutch slave cylinder. It can cause further damage to your clutch system and potentially leave you stranded.

Q: How do I know if my clutch master cylinder or slave cylinder is bad?

A: The symptoms can be similar, but a failing master cylinder often presents with a consistently low or sinking clutch pedal, while a slave cylinder is more likely to leak fluid. A proper diagnosis is recommended.

Q: What happens if I don't bleed the clutch system properly?

A: If you don't bleed the clutch system properly, air will remain in the hydraulic lines, causing a spongy pedal and difficulty shifting gears. You may not be able to fully disengage the clutch.

Q: Can I reuse the brake fluid from the old slave cylinder?

A: No! Never reuse old brake fluid. It can be contaminated with moisture and debris, which can damage your clutch system.