How To Make Ac Blow Cold

Let's dive into the fascinating world of automotive air conditioning and how to coax that refreshingly cold air out of your vents. This article isn't about simply topping off refrigerant; it's about understanding the system, its components, and how to troubleshoot common issues. Whether you're looking to diagnose a failing AC system, planning a modification, or simply want to gain a deeper understanding of your car's inner workings, this knowledge is invaluable.

Understanding the AC System: A Deep Dive

The purpose of understanding the AC system is multifaceted. Primarily, it empowers you to diagnose problems effectively, saving time and money on potentially unnecessary repairs. Secondly, a solid grasp of the system allows for informed decisions when choosing replacement parts or considering performance upgrades. Finally, it promotes safer and more confident DIY work.

Key Specs and Main Parts

The automotive AC system is a closed-loop refrigeration cycle. The main components are interconnected and rely on the properties of a refrigerant (usually R-134a or the newer R-1234yf, but we will refer to the general term of refrigerant for this document) to transfer heat from inside the cabin to the outside atmosphere. Key specifications to understand are pressures (high and low side), refrigerant type and quantity, and operating temperatures.

- Compressor: The heart of the system. It compresses the low-pressure, low-temperature refrigerant vapor into a high-pressure, high-temperature vapor. This compression is crucial for the refrigeration cycle.

- Condenser: Located typically in front of the radiator, the condenser receives the high-pressure, high-temperature refrigerant vapor from the compressor. Here, the refrigerant releases heat to the outside air and condenses into a high-pressure, high-temperature liquid.

- Receiver/Drier (or Accumulator): This component performs two crucial functions. It filters out contaminants (like moisture and debris) from the refrigerant and acts as a reservoir for liquid refrigerant. The drier contains a desiccant that absorbs moisture. Some systems use an accumulator instead of a receiver/drier; the accumulator is typically found on the low-pressure side of the system and contains an orifice tube.

- Expansion Valve (or Orifice Tube): This metering device controls the flow of high-pressure liquid refrigerant into the evaporator. As the refrigerant passes through the valve or orifice, it experiences a significant pressure drop, causing it to rapidly expand and cool.

- Evaporator: Located inside the cabin, the evaporator is where the magic happens. The low-pressure, low-temperature refrigerant liquid absorbs heat from the air passing over it (air drawn from the cabin), causing the refrigerant to vaporize. This process chills the air that is then blown into the cabin.

- Refrigerant Lines: These hoses and pipes transport the refrigerant throughout the system. They are designed to withstand the high pressures and temperatures involved.

- Pressure Switches: These switches monitor the refrigerant pressure and provide signals to the vehicle's computer to control the compressor and cooling fans. Low-pressure and high-pressure switches protect the system from damage in case of refrigerant leaks or over-pressurization.

Deciphering AC System Diagrams: Understanding Symbols

AC system diagrams utilize standard symbols to represent different components and connections. Understanding these symbols is essential for interpreting the diagram and troubleshooting the system. For example, a circle with an "X" through it might represent a compressor, while a zig-zag line represents a condenser or evaporator. A diamond-shaped symbol often indicates a receiver/drier.

- Lines: Solid lines typically represent refrigerant lines, while dashed lines may indicate electrical wiring. The thickness of the line can sometimes indicate the size or type of the connection.

- Colors: Color-coding can be used to differentiate between high-pressure and low-pressure lines. For example, red might represent high-pressure lines, while blue represents low-pressure lines. However, color coding varies between manufacturers, so always refer to the diagram's legend.

- Icons: Specific icons are used to represent individual components, such as the compressor, condenser, expansion valve, and evaporator. These icons are usually standardized but may vary slightly between diagrams.

How It Works: The Refrigeration Cycle Explained

The AC system operates based on the principles of thermodynamics and phase changes. Here's a breakdown of the cycle:

- Compression: The compressor compresses the low-pressure, low-temperature refrigerant vapor, increasing both its pressure and temperature.

- Condensation: The high-pressure, high-temperature refrigerant vapor flows to the condenser, where it releases heat to the outside air and condenses into a high-pressure, high-temperature liquid.

- Metering: The high-pressure liquid refrigerant passes through the expansion valve (or orifice tube), where it experiences a sudden pressure drop. This causes the refrigerant to rapidly expand and cool into a low-pressure, low-temperature liquid.

- Evaporation: The low-pressure, low-temperature refrigerant liquid enters the evaporator, where it absorbs heat from the air blowing across it. This causes the refrigerant to vaporize into a low-pressure, low-temperature vapor, chilling the air that is blown into the cabin.

- Return: The low-pressure, low-temperature refrigerant vapor returns to the compressor, completing the cycle.

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips you can use to diagnose common AC problems:

- Check the Compressor Clutch: Verify that the compressor clutch is engaging when the AC is turned on. If the clutch is not engaging, the compressor is not operating, and the system will not cool. Listen for a distinct clicking sound when the AC is switched on. A faulty pressure switch or a blown fuse could prevent the clutch from engaging.

- Inspect Refrigerant Lines: Look for signs of leaks, such as oily residue or dirt accumulation, on the refrigerant lines and fittings. Leaks can cause a loss of refrigerant, which reduces the system's cooling capacity.

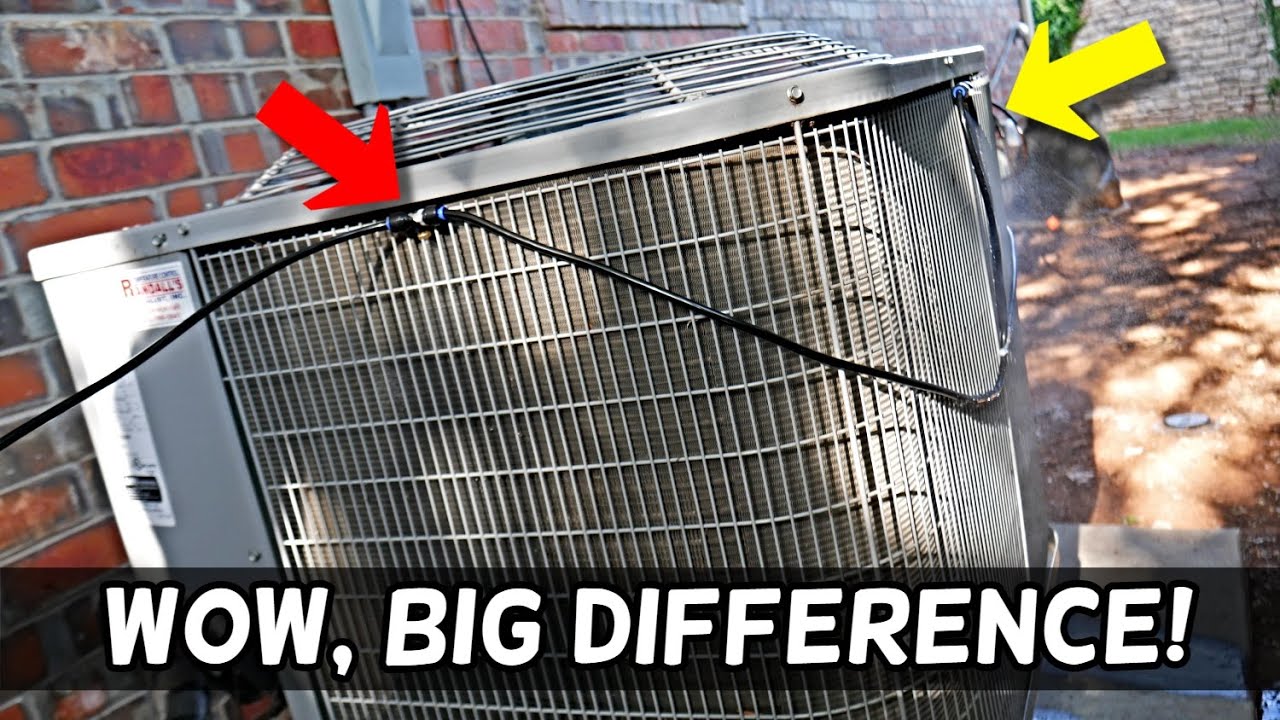

- Check for Obstructions: Ensure that the condenser and radiator are free of debris, such as leaves and insects. Obstructions can restrict airflow and reduce the efficiency of the system.

- Gauge Readings: Using a manifold gauge set, check the high-side and low-side pressures. Abnormal pressures can indicate various problems, such as a low refrigerant charge, a clogged expansion valve, or a faulty compressor. Note that diagnosing pressure readings requires training and experience, a reference guide is invaluable.

- Temperature Differential: Use a thermometer to measure the temperature of the air coming out of the vents. A significant temperature differential between the ambient air and the vent air indicates that the AC system is working properly.

Safety First: Risky Components and Procedures

Working on an AC system involves handling high-pressure refrigerants and potentially dangerous electrical components. Always wear safety glasses and gloves when working on the system.

- Refrigerant: Refrigerant can cause frostbite if it comes into contact with skin. Never release refrigerant into the atmosphere. Recover refrigerant using a proper recovery machine.

- High Pressure: The system operates at high pressures. Never disconnect refrigerant lines or components without first properly evacuating the system.

- Electrical Components: Be aware of the electrical components in the system, such as the compressor clutch and pressure switches. Disconnect the battery before working on any electrical components.

- Compressor Oil: Refrigerant oil is used to lubricate the compressor. Use the correct oil for your system. Incorrect oil can damage the compressor.

Remember, AC systems can be complex, and some repairs require specialized tools and knowledge. If you're not comfortable performing a particular task, it's always best to consult a qualified mechanic.

We have a detailed AC system diagram file available for download. This diagram provides a comprehensive overview of the system and can be a valuable resource for troubleshooting and repairs. Contact us for download instructions!