How To Make A/c Blow Colder

Making Your A/C Blow Arctic: A DIYer's Guide to Colder Air

Summer's heat can turn your car into an oven, making a functioning air conditioning system a necessity, not a luxury. While some A/C issues require professional attention, many can be addressed by the experienced DIYer. This guide will walk you through the components of your A/C system, common problems, and practical steps you can take to improve its cooling performance. This knowledge empowers you to perform basic troubleshooting, potentially saving you money on expensive repairs and keeping you cool on the road.

Why Understand the A/C System?

Understanding the A/C system is beneficial for several reasons:

- Troubleshooting: Quickly identify potential issues before they escalate.

- Preventive Maintenance: Implement measures to maintain system efficiency and longevity.

- DIY Repairs: Perform simple tasks like refrigerant top-offs or component replacements with confidence.

- Informed Discussions: Communicate effectively with mechanics about necessary repairs.

- Performance Upgrades: Understand the limitations of your system and how to safely improve its cooling capability.

Key Specs and Main Parts of Your A/C System

The automotive A/C system is a closed-loop refrigeration cycle that uses refrigerant to absorb and release heat. Here's a breakdown of the key components:

- Compressor: The heart of the system, the compressor circulates the refrigerant and increases its pressure and temperature. It's typically driven by the engine via a belt. A key spec is its displacement (cubic centimeters), which indicates its pumping capacity.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the high-pressure, hot refrigerant, causing it to condense into a liquid. Fin density (fins per inch) is important for efficient heat exchange.

- Receiver-Drier (or Accumulator): This component filters contaminants and removes moisture from the refrigerant. It also provides a reservoir for liquid refrigerant. Replace this component whenever the system is opened to atmosphere.

- Expansion Valve (or Orifice Tube): This valve regulates the flow of refrigerant into the evaporator, causing a pressure drop and allowing the liquid refrigerant to expand and vaporize. The valve's capacity (tons of refrigeration) is a critical specification.

- Evaporator: Located inside the vehicle's HVAC (Heating, Ventilation, and Air Conditioning) unit, the evaporator absorbs heat from the cabin air as the refrigerant evaporates. Like the condenser, fin density is crucial.

- Refrigerant: The working fluid of the system, typically R-134a or R-1234yf (newer vehicles). Using the wrong refrigerant can damage the system.

- HVAC Control System: This includes the controls on your dashboard, the blend doors that control airflow, and the blower motor that moves air across the evaporator.

Understanding A/C System Symbols and Lines

A/C system diagrams use specific symbols to represent components and lines to represent refrigerant flow. Here's a general guide:

- Solid Lines: Represent refrigerant lines. Heavier lines usually indicate high-pressure lines, while thinner lines indicate low-pressure lines.

- Dotted Lines: Often represent electrical wiring or vacuum lines.

- Circles: Can represent components like the compressor, condenser, or receiver-drier. Look for labels or adjacent text to identify the specific component.

- Squares/Rectangles: Often represent electrical components like relays or switches.

- Arrows: Indicate the direction of refrigerant flow.

- Colors: Some diagrams use colors to distinguish between high-pressure (often red) and low-pressure (often blue) lines.

How the A/C System Works: A Simplified Explanation

The A/C system works on the principle of heat transfer through refrigerant phase changes. Here's the cycle:

- Compression: The compressor draws in low-pressure, low-temperature refrigerant vapor and compresses it, increasing its pressure and temperature. This hot, high-pressure vapor is then discharged.

- Condensation: The hot, high-pressure refrigerant vapor flows into the condenser. As air flows across the condenser, it dissipates heat from the refrigerant, causing it to condense into a high-pressure, warm liquid.

- Metering: The high-pressure liquid refrigerant flows through the receiver-drier (or accumulator) to remove moisture and contaminants. It then reaches the expansion valve (or orifice tube), where it experiences a dramatic pressure drop. This sudden drop causes the refrigerant to partially vaporize and become very cold.

- Evaporation: The cold, low-pressure refrigerant flows into the evaporator. As warm air from the cabin is blown across the evaporator, it absorbs heat from the air, causing the remaining liquid refrigerant to vaporize completely. This process cools the air, which is then blown into the cabin.

- Cycle Repeat: The low-pressure, low-temperature refrigerant vapor returns to the compressor, and the cycle repeats.

Real-World Use: Basic A/C Troubleshooting Tips

Here are a few troubleshooting tips you can use to diagnose common A/C problems:

- Check Refrigerant Levels: Use an A/C manifold gauge set to measure the high-side and low-side pressures. Compare these readings to the manufacturer's specifications (found in your vehicle's repair manual). Low refrigerant is a common cause of poor cooling.

- Inspect the Compressor Clutch: With the A/C turned on, verify that the compressor clutch is engaging. If it's not engaging, check the electrical connections to the compressor and the A/C relay. A blown fuse can also prevent the clutch from engaging.

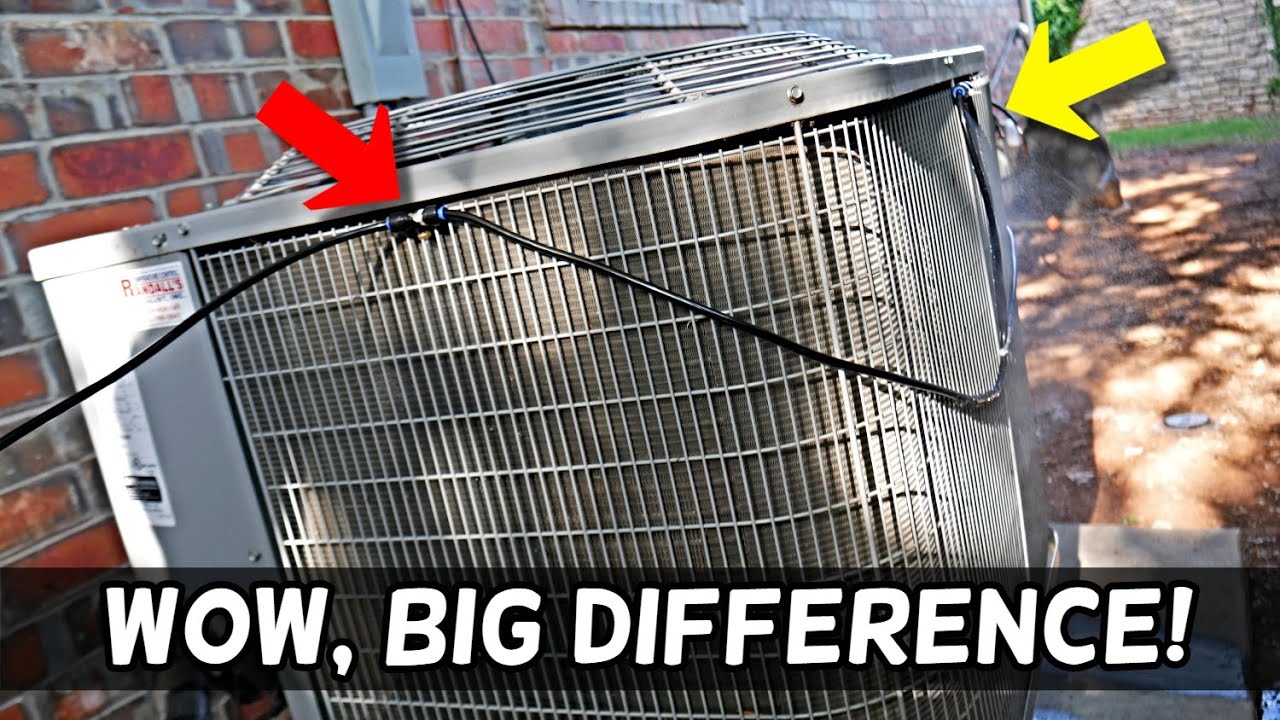

- Check the Condenser Fan: The condenser fan helps to dissipate heat from the condenser. Make sure the fan is running when the A/C is on. If not, check the fan motor and its electrical connections.

- Feel the Refrigerant Lines: With the A/C running, carefully feel the refrigerant lines. The high-pressure line (between the compressor and condenser) should be hot, and the low-pressure line (between the evaporator and compressor) should be cool. If these lines aren't at the expected temperatures, it could indicate a problem with the compressor, expansion valve, or refrigerant flow. Be cautious – these lines can get very hot.

- Inspect the Cabin Air Filter: A clogged cabin air filter can restrict airflow to the evaporator, reducing cooling performance. Replace the filter regularly.

Safety Precautions: Working with Refrigerant and High Pressures

Working with A/C systems can be dangerous. Here are some important safety precautions:

- Refrigerant is harmful: Avoid direct contact with refrigerant. It can cause frostbite and is harmful if inhaled. Wear safety glasses and gloves when working with refrigerant.

- High pressures are dangerous: A/C systems operate at high pressures. Never disconnect refrigerant lines without first properly recovering the refrigerant using a recovery machine.

- Electrical Hazards: Be aware of electrical components in the A/C system, such as the compressor clutch and condenser fan. Disconnect the battery before working on electrical components.

- Professional Recovery: It is illegal and environmentally irresponsible to vent refrigerant into the atmosphere. Always use a certified recovery machine to recover refrigerant. Consider having a professional handle refrigerant-related tasks.

- Proper Ventilation: Work in a well-ventilated area when handling refrigerants.

Refrigerant is extremely cold and can cause severe frostbite upon contact. Always wear appropriate personal protective equipment (PPE) when handling refrigerant.

Remember, this guide provides a basic overview of A/C system maintenance and troubleshooting. Complex repairs should always be performed by a qualified technician.

We have a detailed A/C system diagram available for download. It provides a visual representation of the system's components and refrigerant flow, making it easier to understand and troubleshoot problems.