How To Move Electric Seat Manually

Electric seats offer convenience and adjustability, but what happens when they stop working? Whether it's a blown fuse, a faulty motor, or a more complex electrical issue, being stranded with an uncomfortably positioned seat can be a real pain. This article provides a comprehensive guide on how to manually move an electric seat when the power fails. We'll cover the mechanics, potential problems, and best practices to get you back in a comfortable driving position safely.

Understanding the Electric Seat System

Before diving into manual operation, let's establish a baseline understanding of the system itself. Electric seats rely on a network of components to achieve their movement. This system generally consists of:

- Seat Adjustment Motors: These are small, DC electric motors responsible for driving each specific movement – forward/backward, up/down, tilt, and lumbar support. Each direction usually has its own dedicated motor.

- Seat Adjustment Switch(es): These are the controls you use to command the seat's movement. They send electrical signals to the control module.

- Control Module (Seat ECU): The electronic control unit acts as the brain of the system. It receives signals from the switches and relays power to the appropriate motors. In some vehicles, this functionality is integrated into the body control module (BCM).

- Wiring Harness: This network of wires connects all the components, carrying power and signals.

- Fuses and Relays: These protect the system from overloads and control the flow of current.

- Gearboxes/Drive Cables: The motors usually don't directly move the seat. They drive a series of gears or flexible drive cables that translate the motor's rotation into linear movement of the seat frame.

The motors themselves are usually small permanent magnet DC (PMDC) motors. The control module uses relays to switch the polarity of the voltage applied to the motor, allowing it to spin in either direction. The gearbox reduces the speed and increases the torque of the motor, making it possible to move the heavy seat frame against the occupant's weight.

Technical Breakdown: How Manual Movement Works (or Doesn't)

While electric seats are designed for powered movement, there are a few approaches to manually adjust them. The feasibility and method depend heavily on the seat's design. Some seats are inherently easier to move manually than others. The primary challenge is overcoming the resistance of the gearbox and motor connected to the seat mechanism.

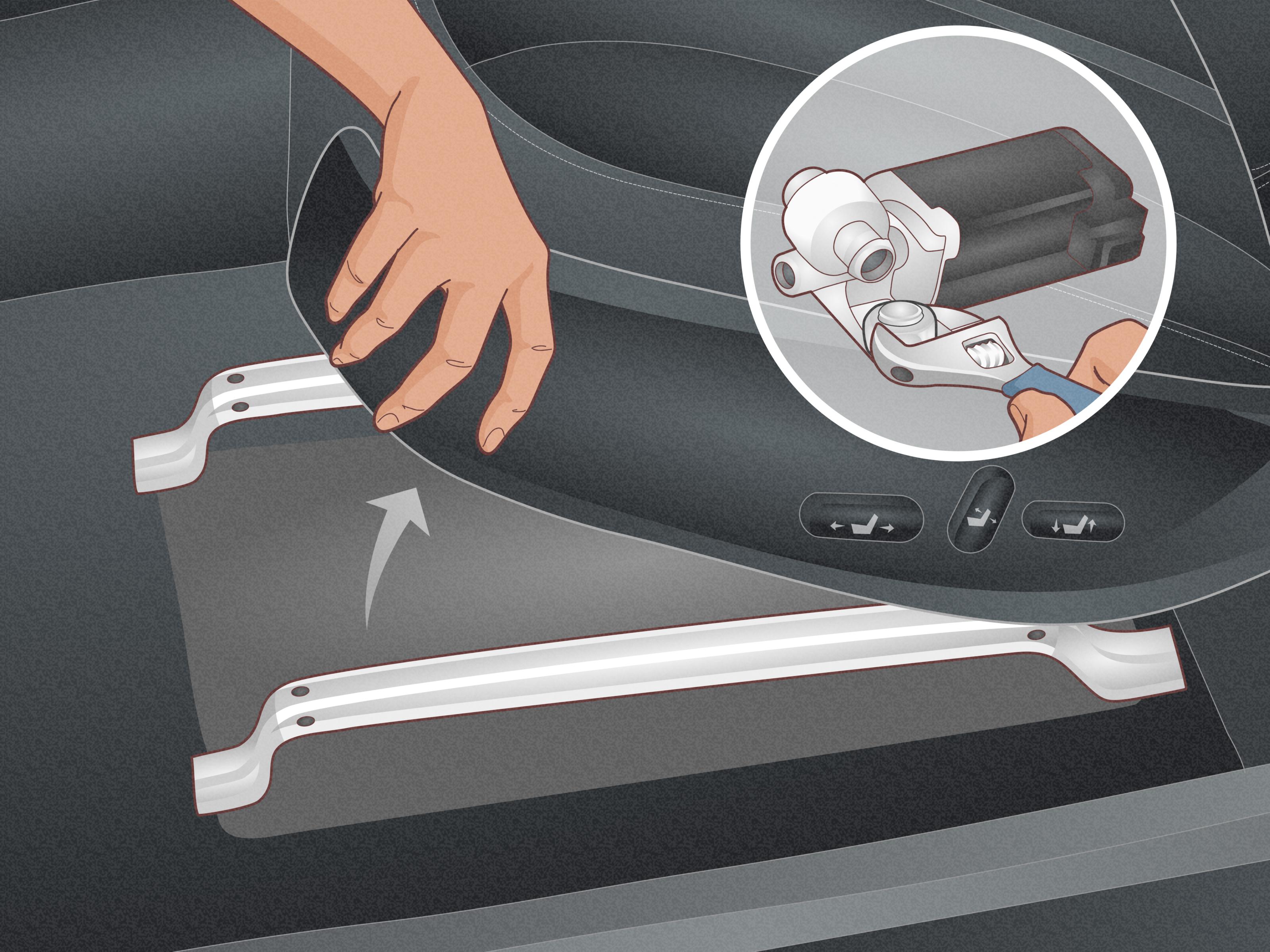

Method 1: Accessing and Turning the Motor Shaft Directly

This is the most direct, but often the most difficult, method. It involves physically accessing the motor and turning its shaft. This requires identifying the specific motor controlling the desired movement (e.g., forward/backward). Accessing the motor usually involves removing seat trim panels. Here's the process:

- Safety First: Disconnect the negative terminal of the car battery to prevent accidental activation of the seat motors or other electrical components during your work.

- Access the Motor: Carefully remove the plastic trim panels around the seat base to expose the seat motors. You'll likely need a variety of screwdrivers (Phillips, flathead, Torx) and possibly plastic trim removal tools to avoid damaging the panels.

- Identify the Motor: Each motor is typically labeled or connected to a specific drive cable. Trace the cable to determine which motor controls which movement.

- Expose the Motor Shaft: The motor shaft is often partially obscured by the gearbox. You might need to carefully disassemble a small portion of the gearbox housing to gain access. Be extremely careful not to damage any gears or internal components. Take pictures as you disassemble to aid reassembly.

- Turn the Shaft: Using pliers or a small wrench, gently attempt to turn the motor shaft. It will likely require some force due to the gearbox. If the shaft is seized, do not force it. Spraying a small amount of penetrating oil (e.g., WD-40) into the gearbox might help loosen it.

- Repeat as Necessary: Continue turning the shaft until the seat reaches the desired position.

- Reassemble: Carefully reassemble the gearbox components and trim panels.

- Reconnect the Battery: Reconnect the negative battery terminal.

Important Considerations: This method is not recommended if you lack mechanical experience. Forcing the motor shaft can damage the gearbox or the motor itself. Also, on some newer vehicles, the motor shaft might be completely inaccessible without significant disassembly, making this method impractical.

Method 2: Manipulating the Drive Cables

Some electric seat systems use flexible drive cables (similar to those used in speedometer cables) to transmit power from the motor to the seat mechanism. If you can access these cables, you might be able to manipulate them directly.

- Access the Cables: Similar to the previous method, you'll need to remove seat trim panels to expose the drive cables.

- Identify the Target Cable: Determine which cable controls the movement you want to adjust.

- Turn the Cable: Using pliers or your fingers (if possible), attempt to turn the cable. This may require more force than turning the motor shaft directly, as you are now acting on the entire gear train.

Important Considerations: Drive cables are often fragile and can be easily damaged if bent or twisted excessively. Apply force gently and evenly. Also, accessibility can be a major limitation.

Method 3: Bypassing the Motor (Rare and Complex)

This method involves disconnecting the motor from the gearbox and manually moving the seat frame directly. This is rarely feasible and requires a deep understanding of the seat mechanism. It typically involves:

- Disassembling the Seat Frame: This involves removing bolts and fasteners that connect the motor and gearbox to the seat frame. This is often complex and requires specialized tools.

- Disconnecting the Motor: Carefully detach the motor and gearbox assembly from the seat frame.

- Manually Moving the Seat: Once the motor is disconnected, you should be able to manually slide or adjust the seat frame.

Important Considerations: This method is only recommended as a last resort for experienced mechanics. It can be extremely difficult and time-consuming and carries a high risk of damaging the seat.

Common Issues and Maintenance Concerns

Understanding common problems with electric seats can help you diagnose the issue and potentially avoid the need for manual manipulation. Here are some typical culprits:

- Blown Fuse: The most common cause is a blown fuse in the seat's power circuit. Check the fuse box diagram in your owner's manual to locate the correct fuse and replace it with one of the same amperage.

- Faulty Switch: A malfunctioning switch can prevent the signal from reaching the control module. Test the switch with a multimeter if you have experience with electrical testing.

- Wiring Problems: Damaged or corroded wiring can interrupt the flow of power or signals. Inspect the wiring harness for any visible damage.

- Faulty Motor: The motor itself can fail due to wear and tear or overheating. Testing a motor directly involves applying 12VDC and checking for functionality.

- Seized Gearbox: Lack of lubrication or debris accumulation can cause the gearbox to seize.

- Control Module Failure: Although less common, the control module can fail, preventing it from relaying power to the motors.

Preventative Maintenance: Regularly cleaning the seat tracks and lubricating the moving parts can help prevent future issues. Use a silicone-based lubricant to avoid attracting dust and dirt.

Do's and Don'ts / Best Practices

- DO: Disconnect the battery before working on any electrical components.

- DO: Use the correct tools for the job.

- DO: Take pictures as you disassemble components to aid reassembly.

- DO: Apply penetrating oil sparingly if a component is seized.

- DON'T: Force anything. If something doesn't move easily, investigate the cause.

- DON'T: Work on the system if you are not comfortable with basic mechanical tasks.

- DON'T: Ignore unusual noises or behavior from the seat. Address issues promptly to prevent further damage.

Best Practices: Start with the simplest solutions first (e.g., checking the fuse). Consult your vehicle's service manual for specific instructions and diagrams. If you're unsure about any step, seek professional assistance.

Conclusion

Manually moving an electric seat is often a challenging and potentially risky task. While direct methods involving the motor shaft or drive cables offer the most direct approach, they require careful execution and a degree of mechanical aptitude. Bypassing the motor is usually only suitable for experienced mechanics. Prioritize diagnosing the root cause of the problem and attempting simpler solutions, like checking fuses and inspecting wiring. If manual manipulation is necessary, proceed with caution and prioritize safety. When in doubt, seeking assistance from a qualified mechanic is always the best course of action to avoid further damage and ensure a safe and functional seat.