How To Oil A Sequential Turbo Setup

Maintaining the health of a turbocharger is paramount to ensuring optimal engine performance and longevity. While a single turbo setup involves relatively straightforward lubrication, sequential turbo systems present a more complex challenge. Insufficient or improper lubrication can lead to catastrophic turbo failure, resulting in significant repair costs and downtime. Understanding the intricacies of oiling a sequential setup is therefore crucial for any enthusiast or aspiring automotive engineer.

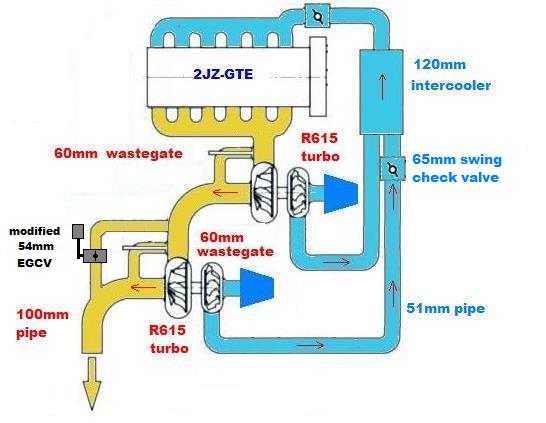

The Challenge: Delivering Oil to Two Turbos, Strategically

Imagine trying to water two separate gardens using a single hose, but one garden needs significantly more water than the other, especially at certain times. That's essentially the problem a sequential turbo oiling system faces. Unlike a single turbo, where a consistent oil supply meets the demands of a single bearing assembly, a sequential system requires careful management of oil pressure and flow to ensure both turbos receive adequate lubrication, considering their different operational phases.

In a typical sequential setup, one turbocharger (the primary) operates almost continuously, providing boost at low RPMs and continuing as the engine revs higher. The second turbocharger (the secondary) remains dormant until a certain RPM threshold is reached, at which point it kicks in to provide additional boost. This means the secondary turbo needs a minimal amount of oil during its inactive phase, and then a sudden, significant increase in oil supply when it activates.

How Sequential Turbo Oiling Works: A Detailed Look

The oiling system for a sequential turbo setup is designed to address this fluctuating demand. Here's a breakdown of the key components and their functions:

- Oil Pump: The heart of the system, providing pressurized oil throughout the engine, including the turbochargers. A robust oil pump is essential for meeting the demands of two turbos.

- Oil Filter: Removes contaminants from the oil, preventing wear and damage to the turbocharger bearings. Regular oil and filter changes are even more critical in a sequential setup due to the increased complexity and sensitivity.

- Oil Lines: These deliver oil from the engine's main oil gallery to each turbocharger. The lines are typically made of braided stainless steel to withstand high pressures and temperatures.

- Oil Restrictors (if applicable): Some systems incorporate oil restrictors in the oil feed lines to the turbochargers. These restrictors limit the amount of oil flowing to the turbos, particularly at higher engine speeds. This prevents over-oiling, which can lead to oil leaks and increased oil consumption. Restrictors are more common on ball-bearing turbos, which require less oil than journal-bearing turbos.

- Check Valves (Crucial for Secondary Turbo): These prevent oil from draining back out of the secondary turbo when it's not in use. This ensures that oil is immediately available when the secondary turbo kicks in, minimizing wear and lag.

- Oil Drain Lines: These return oil from the turbochargers to the engine's oil pan. The drain lines must be large enough and have a sufficient downward angle to allow for proper oil drainage. Poor drainage can lead to oil backing up in the turbocharger, causing smoking and ultimately, turbo failure. Gravity is your friend here – ensure the drain lines flow downwards freely.

The key difference between a single turbo oiling system and a sequential system lies in the management of oil flow to the secondary turbo. The check valve is paramount. When the secondary turbo is inactive, the check valve prevents oil from seeping out. When the secondary turbo activates and the oil pressure increases, the check valve opens, allowing oil to flow freely to the turbocharger's bearings.

The diameter and material of the oil lines are also important. Braided stainless steel lines offer superior heat resistance and durability compared to rubber lines, which can deteriorate over time and lead to oil leaks. The diameter of the lines must be sufficient to provide adequate oil flow to both turbos under all operating conditions. Insufficient flow can starve the turbochargers of oil, leading to bearing damage.

Scenario: The Mazda RX-7 (FD3S)

The Mazda RX-7 (FD3S) is a classic example of a vehicle equipped with a sequential turbo system. Its 13B-REW rotary engine utilizes two Hitachi HT-12 turbos arranged sequentially. The system is renowned for its complexity, and proper oiling is absolutely critical for its reliable operation. In the RX-7, the primary turbo provides boost from low RPMs, while the secondary turbo engages at around 4500 RPM. The Mazda's system employs check valves to prevent oil drain-back from the secondary turbo and precisely calibrated oil restrictors to ensure proper lubrication without over-oiling.

Pros and Cons of Sequential Turbo Systems

Pros:

- Reduced Turbo Lag: Sequential systems minimize turbo lag by utilizing a smaller primary turbocharger that spools up quickly at low RPMs.

- Improved Low-End Torque: The primary turbocharger provides ample low-end torque, making the engine more responsive in everyday driving.

- Increased Top-End Power: The secondary turbocharger kicks in at higher RPMs to provide a significant boost in power.

- Wider Powerband: The combination of the primary and secondary turbos results in a wider powerband compared to a single turbo setup.

Cons:

- Increased Complexity: Sequential systems are more complex than single turbo systems, making them more difficult to diagnose and repair.

- Higher Maintenance Costs: The increased complexity of sequential systems can lead to higher maintenance costs. The oiling system requires meticulous attention.

- Potential for Turbo Failure: If the oiling system is not properly maintained, the turbochargers can fail prematurely.

- Heat Management: Sequential turbo systems generate more heat than single turbo systems, requiring efficient cooling systems.

Use Cases

Sequential turbo systems are typically found in high-performance vehicles where both low-end torque and top-end power are desired. They are commonly used in sports cars, rally cars, and other vehicles where responsiveness and a wide powerband are essential. Examples include:

- Mazda RX-7 (FD3S)

- Porsche 959

- Certain Subaru models (Legacy, Outback in some markets)

In the aftermarket, sequential turbo systems are less common than single turbo systems due to their complexity and higher cost. However, they can be a viable option for enthusiasts who are willing to invest the time and effort to properly maintain them.

Real-World Insights and Recommendations

Based on real-world experience and common failure points, here are some crucial recommendations for maintaining a sequential turbo oiling system:

- Use High-Quality Oil: Synthetic oil is highly recommended for turbocharger applications due to its superior heat resistance and lubricating properties. Choose an oil viscosity recommended by the vehicle manufacturer or a reputable tuner specializing in your specific engine.

- Change Oil Regularly: Shorten the oil change interval compared to naturally aspirated engines. Turbochargers put immense stress on the oil. A 3,000-mile (5,000 km) oil change interval is a good starting point, but consider more frequent changes if you drive aggressively or in harsh conditions.

- Inspect Oil Lines Regularly: Check the oil lines for any signs of leaks, cracks, or deterioration. Replace any damaged lines immediately.

- Ensure Proper Oil Drainage: Verify that the oil drain lines are not kinked or blocked and that they have a sufficient downward angle. Poor drainage is a major cause of turbo failure.

- Monitor Oil Pressure: Install an oil pressure gauge to monitor the oil pressure in the system. Low oil pressure can indicate a problem with the oil pump or other components.

- Pre-Lube the Turbos: After an oil change or any work that involves disconnecting the oil lines, pre-lube the turbos by disconnecting the ignition or fuel pump and cranking the engine for several seconds to allow oil to circulate through the turbochargers before starting the engine. This is crucial to prevent dry starts, which can damage the bearings.

- Consider an Oil Accumulator: For vehicles that are driven aggressively, an oil accumulator can provide a резерв of oil pressure during hard cornering or braking, preventing oil starvation to the turbochargers.

- Don't Ignore Warning Signs: Pay attention to any warning signs, such as smoking from the exhaust, a loss of power, or unusual noises from the turbochargers. These can indicate a problem with the oiling system or the turbos themselves.

- Proper Cool-Down: After spirited driving, allow the engine to idle for a few minutes before shutting it off. This allows the turbochargers to cool down and prevents oil from coking in the bearings.

Maintaining a sequential turbo oiling system requires a proactive approach and a thorough understanding of its components and their functions. By following these recommendations, you can significantly extend the life of your turbochargers and enjoy the benefits of a sequential turbo system for years to come. Always consult with a qualified mechanic or tuner if you have any questions or concerns about your turbo oiling system. Neglecting this crucial aspect of engine maintenance can lead to costly repairs and potentially irreversible damage.