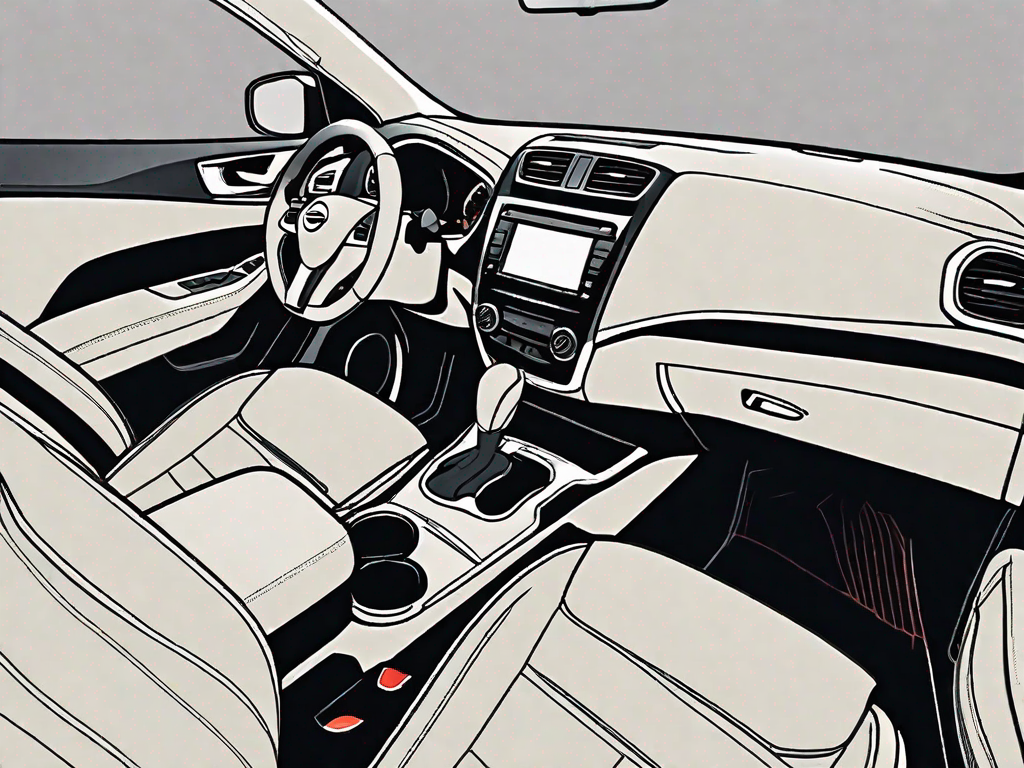

How To Put A Nissan Rogue In Reverse

Understanding how to properly engage reverse in your Nissan Rogue might seem trivial, but it's a crucial aspect of vehicle operation and preventative maintenance. Many drivers take this function for granted, but improper technique or ignoring subtle warning signs can lead to premature wear and tear on your transmission. This guide delves into the mechanics of putting your Rogue in reverse, common issues you might encounter, and best practices to ensure smooth and reliable operation.

Background: The Nissan Rogue's Transmission System

The Nissan Rogue, depending on the model year, typically utilizes a Continuously Variable Transmission (CVT). While some older Rogues might have used a traditional automatic transmission, the CVT has become the standard. Understanding this distinction is critical. A CVT doesn't have fixed gears like a traditional automatic. Instead, it uses a system of pulleys and a belt or chain to create an infinite range of gear ratios within its operating range. This allows the engine to stay in its optimal power band more consistently, resulting in improved fuel efficiency. However, the design and operation of a CVT differs significantly from a traditional automatic, and the reverse engagement process reflects these differences.

The specific CVT model used in your Rogue can vary. For instance, earlier models often featured the Jatco JF011E. More recent versions have utilized updated designs. These CVTs are electronically controlled, meaning the Transmission Control Module (TCM) is responsible for managing shifting and, importantly, the engagement of reverse. This computer-controlled operation means the TCM relies on a series of sensors (such as vehicle speed, engine speed, throttle position, and transmission fluid temperature) to determine the optimal time and method for shifting.

Technical Breakdown: How Reverse Engagement Works

Engaging reverse in a Rogue equipped with a CVT involves a specific sequence of events orchestrated by the TCM. Here's a detailed breakdown:

1. Driver Input: Shifter Position

The process begins when the driver moves the gear selector to the "R" (Reverse) position. This action signals the TCM that the driver intends to move the vehicle backward. The gear selector itself is connected to the TCM via electrical circuits. The TCM receives a signal indicating the requested gear.

2. TCM Evaluation and Pre-Conditions

Before engaging reverse, the TCM performs a series of checks. It verifies the following conditions:

- Vehicle Speed: The vehicle must be at a complete stop. Any forward motion will prevent reverse engagement to protect the transmission. The TCM relies on signals from wheel speed sensors to determine vehicle speed.

- Brake Pedal Position: In many cases, the brake pedal must be depressed. This is a safety feature to prevent accidental movement when engaging reverse. A brake pedal position sensor provides input to the TCM.

- Engine Speed (RPM): The engine speed must be within an acceptable range, usually near idle. Excessive RPM can damage the transmission during engagement.

- Transmission Fluid Temperature: The TCM monitors the transmission fluid temperature. Extremely high or low temperatures can affect the fluid's viscosity and lubrication properties, potentially damaging internal components during reverse engagement. If the temperature is outside the acceptable range, the TCM might delay or prevent reverse engagement.

3. Actuation of the Reverse Mechanism

Once the TCM has verified all pre-conditions, it initiates the engagement of the reverse mechanism. In a CVT, the process is slightly different compared to a traditional automatic transmission. Since CVTs do not have fixed gears, reverse is typically achieved through a planetary gear set, a one-way clutch, or a similar arrangement within the transmission housing. This mechanism effectively reverses the direction of the output shaft. The TCM actuates this mechanism through a series of solenoids and hydraulic valves within the transmission. These solenoids control the flow of transmission fluid to specific actuators, which in turn engage the reverse mechanism.

4. Confirmation and Engagement

After the reverse mechanism is engaged, the TCM monitors sensors to confirm successful operation. This includes monitoring the output shaft speed and verifying that it is rotating in the reverse direction. If the TCM detects any anomalies, such as slippage or excessive vibration, it might disengage reverse and display a warning light on the instrument panel. The "R" indicator light on the gear selector will also illuminate to confirm that reverse is engaged.

Common Issues and Maintenance Concerns

Several issues can arise that affect the ability to smoothly and reliably engage reverse in your Rogue:

- Low Transmission Fluid: Insufficient transmission fluid can cause slippage and difficulty engaging gears, including reverse. This is because the hydraulic pressure required to actuate the reverse mechanism is reduced.

- Dirty or Degraded Transmission Fluid: Old or contaminated transmission fluid loses its lubricating properties and can clog hydraulic passages, hindering the proper operation of the transmission. Always use the correct Nissan CVT fluid.

- Faulty Solenoids: The solenoids that control the hydraulic valves can fail, preventing the reverse mechanism from engaging. This can be diagnosed with a scan tool that can read transmission diagnostic trouble codes (DTCs).

- Sensor Issues: Malfunctioning sensors, such as the vehicle speed sensor, brake pedal position sensor, or transmission fluid temperature sensor, can send incorrect information to the TCM, preventing reverse engagement.

- TCM Malfunction: In rare cases, the TCM itself can fail, leading to various transmission problems, including difficulty engaging reverse.

- Worn CVT Belt/Chain or Pulleys: Over time, the CVT belt or chain and the pulleys can wear. While this more often affects forward gear operation, extreme wear can impact the overall performance of the transmission, potentially including reverse engagement.

- Shift Linkage Issues: Although less common on modern vehicles with electronic shifters, mechanical shift linkage can become loose or misadjusted, preventing the gear selector from properly signaling the TCM to engage reverse.

Regular transmission fluid changes, using the specific Nissan CVT fluid recommended for your vehicle, are crucial for maintaining the health of your transmission and preventing these issues. Consult your owner's manual for the recommended service interval.

Do's and Don'ts / Best Practices

Do's:

- Come to a Complete Stop: Always ensure the vehicle is completely stationary before shifting into reverse.

- Apply the Brakes: Keep your foot firmly on the brake pedal while shifting into reverse.

- Use Genuine Nissan CVT Fluid: Use the correct Nissan CVT fluid as specified in your owner's manual when performing a transmission fluid change. Different fluids can damage the transmission.

- Monitor for Warning Signs: Pay attention to any unusual noises, vibrations, or delays when shifting into reverse. These could be early indicators of a problem.

- Get Regular Transmission Service: Follow the manufacturer's recommended maintenance schedule for transmission fluid changes.

- Check Fluid Level Regularly: While many modern vehicles do not have a dipstick for checking transmission fluid level, it's still good practice to have the fluid level checked periodically by a qualified mechanic.

Don'ts:

- "Rock" the Vehicle: Avoid rapidly shifting between drive and reverse to "rock" the vehicle if it's stuck. This puts excessive strain on the transmission and can cause damage.

- Shift into Reverse While Moving Forward: Never attempt to shift into reverse while the vehicle is still moving forward. This can cause severe damage to the transmission.

- Ignore Warning Lights: If the "Check Engine" light or a transmission warning light illuminates, have the vehicle inspected by a qualified mechanic as soon as possible.

- Use Additives: Avoid using aftermarket transmission additives unless specifically recommended by Nissan. Some additives can interfere with the CVT's operation and cause damage.

Conclusion

Properly engaging reverse in your Nissan Rogue involves more than just moving the gear selector. Understanding the underlying mechanics, especially the role of the TCM and the specific requirements of a CVT, is essential for maintaining the long-term health of your transmission. By following the do's and don'ts outlined above, and by paying close attention to any warning signs, you can help ensure smooth and reliable reverse operation for years to come. If you experience any persistent difficulties or suspect a transmission problem, it is always best to consult a qualified mechanic for diagnosis and repair. Ignoring seemingly minor issues can lead to much more costly repairs down the road. Regular preventative maintenance is always the best approach. Remember, prevention is cheaper than cure!