How To Rebuild A Cvt Transmission

So, you're thinking about rebuilding your CVT (Continuously Variable Transmission). That's a significant undertaking, but if you're comfortable with complex mechanical systems and have the right tools, it's definitely achievable. This article will walk you through the process, covering the essential steps, common pitfalls, and best practices. We'll assume you have a decent level of mechanical knowledge and have tackled similar automotive repairs before. Let's dive in!

Understanding the CVT

Before we get our hands dirty, let's review what a CVT is and how it works. Unlike traditional automatic transmissions with fixed gear ratios, a CVT uses a belt or chain running between two variable-diameter pulleys to provide a virtually infinite number of gear ratios. This allows the engine to stay in its optimal powerband, resulting in improved fuel economy and smoother acceleration.

How it Works: The Technical Breakdown

The core components of a CVT are:

- Primary Pulley (Input Pulley/Drive Pulley): Connected to the engine, it transmits power to the belt/chain.

- Secondary Pulley (Output Pulley/Driven Pulley): Connected to the differential and ultimately the wheels, it receives power from the belt/chain.

- Belt/Chain: The crucial link between the two pulleys, transferring torque. Usually made of high-strength steel links or a specialized rubber compound reinforced with steel.

- Hydraulic Control System: This system is the "brain" of the CVT. It uses hydraulic pressure, regulated by solenoids and controlled by the Transmission Control Module (TCM), to adjust the diameter of the pulleys.

- Solenoids: Electrically operated valves that control hydraulic fluid flow.

- Valve Body: Contains the solenoids and channels that direct hydraulic fluid.

- Hydraulic Pump: Provides the necessary hydraulic pressure.

- Transmission Control Module (TCM): Receives inputs from various sensors (engine speed, throttle position, vehicle speed) and uses this information to determine the optimal pulley ratios.

- Planetary Gearset (Forward/Reverse): Allows the vehicle to move in both forward and reverse directions. Typically used as a starting device and to change direction.

Here's the magic: The effective gear ratio is determined by the relative diameters of the two pulleys. When the primary pulley is small and the secondary pulley is large, you have a low gear ratio (high torque, low speed). As the primary pulley grows larger and the secondary pulley shrinks, you get a higher gear ratio (low torque, high speed). The TCM constantly adjusts these pulley diameters based on driving conditions, creating a seamless transition between ratios.

The Rebuild Process: Step-by-Step

Rebuilding a CVT is a meticulous process. Proper cleanliness and organization are paramount. It is highly recommended to acquire a factory service manual specific to your CVT model before starting.

- Removal: Disconnect the battery. Drain the transmission fluid. Disconnect all wiring harnesses, shift linkage, and cooler lines connected to the transmission. Support the engine properly before removing the transmission mounts and carefully lowering the transmission.

- External Cleaning: Thoroughly clean the outside of the transmission casing. This prevents dirt from entering the transmission during disassembly.

- Disassembly: Place the transmission on a clean workbench. Take pictures or videos during disassembly! These will be invaluable references during reassembly.

- Valve Body Removal: Carefully remove the valve body. Inspect the solenoids for damage or wear. Label and organize the solenoids as they are often matched to specific positions within the valve body.

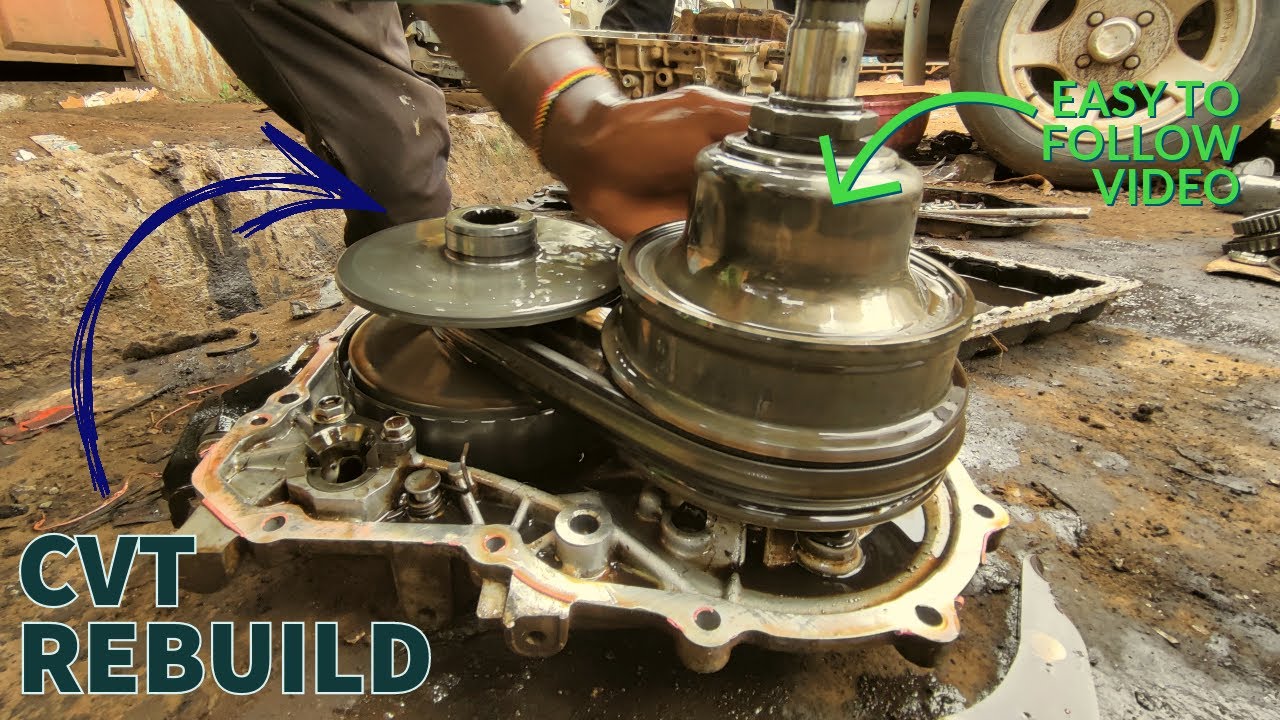

- Pulley Assembly Removal: Disassemble the pulley assemblies. This typically involves specialized tools to compress springs and retainers. Pay close attention to the order and orientation of all components.

- Belt/Chain Inspection: Inspect the belt or chain for wear, damage, or stretching. If you see any signs of damage, replace it.

- Planetary Gearset Inspection: Inspect the planetary gears for wear, pitting, or damage.

- Casing Inspection: Inspect the transmission casing for cracks or damage. Check all threaded holes for damage.

- Cleaning and Inspection: Clean all parts thoroughly with a solvent-based cleaner. Inspect all bearings, seals, bushings, and friction plates for wear or damage. Replace any worn or damaged parts. Critical parts to replace are the seals and friction materials, as they wear over time.

- Component Replacement: Replace all worn or damaged components. This typically includes seals, O-rings, friction plates, and potentially the belt/chain. Consider replacing the filter.

- Valve Body Rebuild (Optional): Rebuild the valve body. This involves cleaning and inspecting the valve body, replacing any worn solenoids, and installing a new valve body gasket kit. This step is recommended, especially if you've experienced shifting problems.

- Reassembly: Reassemble the transmission in the reverse order of disassembly. Use new gaskets and seals. Lubricate all moving parts with transmission fluid during assembly. Ensure all fasteners are tightened to the correct torque specifications. Refer to the service manual for torque values. Pay close attention to the pulley assembly preload specifications, as incorrect preload can cause premature failure.

- Installation: Reinstall the transmission in the vehicle. Connect all wiring harnesses, shift linkage, and cooler lines. Fill the transmission with the correct type and amount of transmission fluid.

- Testing: Start the engine and allow it to warm up. Check the transmission fluid level and add fluid as needed. Drive the vehicle and check for proper shifting and operation. Monitor for any leaks. Perform a TCM reset or relearn procedure as per the manufacturer's recommendations.

Common Issues and Maintenance Concerns

- Slipping: Often caused by worn friction plates or a stretched belt/chain.

- Harsh Shifting: Can be caused by faulty solenoids, a clogged valve body, or low transmission fluid.

- Overheating: Can damage the transmission and is often caused by low fluid, a clogged cooler, or excessive load.

- Fluid Leaks: Replace seals and gaskets to address fluid leaks.

- Preventative Maintenance: Regular fluid changes are crucial for CVT longevity. Use the correct type of fluid specified by the manufacturer. Avoid aggressive driving habits that can put excessive strain on the transmission.

Do's and Don'ts / Best Practices

- DO: Use a clean workspace. Cleanliness is absolutely vital.

- DO: Take pictures and videos during disassembly.

- DO: Label and organize all parts.

- DO: Use the correct tools. Specialized tools are often required for CVT repairs.

- DO: Use a factory service manual.

- DO: Replace all worn or damaged parts.

- DO: Use the correct type of transmission fluid.

- DO: Follow the manufacturer's torque specifications.

- DON'T: Use excessive force when disassembling or reassembling the transmission.

- DON'T: Reuse old seals or gaskets.

- DON'T: Ignore fluid leaks.

- DON'T: Skip the testing phase after reinstallation.

Conclusion

Rebuilding a CVT is a complex undertaking that requires significant mechanical skills and specialized tools. If you're not comfortable with the level of complexity involved, it's best to leave it to a professional. However, if you have the necessary skills, tools, and patience, rebuilding your CVT can save you a significant amount of money and provide a rewarding learning experience. The key is meticulous planning, attention to detail, and a thorough understanding of the transmission's operation. Acquire a factory service manual, take your time, and don't be afraid to ask for help from online forums or experienced mechanics if you get stuck. Remember, replacing all friction components and seals is highly recommended for a lasting rebuild. Good luck!