How To Release Fuel Pressure From Fuel Rail

Releasing fuel pressure from the fuel rail is a crucial step before tackling many fuel system repairs or modifications on your vehicle. Whether you're swapping injectors, replacing a fuel filter, or even diagnosing a fuel delivery problem, failing to depressurize the system can lead to a significant and potentially dangerous fuel spray. This article will walk you through the process, explaining the underlying principles and best practices to ensure a safe and successful outcome.

Background: The Automotive Fuel System

Modern automotive fuel systems are designed to deliver fuel to the engine at a specific pressure. This pressure is maintained by the fuel pump, regulator, and injectors working in concert. Understanding the basics of this system is key to understanding why and how to safely relieve that pressure.

The fuel system typically consists of the following components:

- Fuel Tank: Stores the fuel.

- Fuel Pump: Located either in the tank or externally, it draws fuel from the tank and pushes it towards the engine.

- Fuel Filter: Removes contaminants from the fuel to protect the injectors.

- Fuel Line: Transports fuel from the tank to the engine.

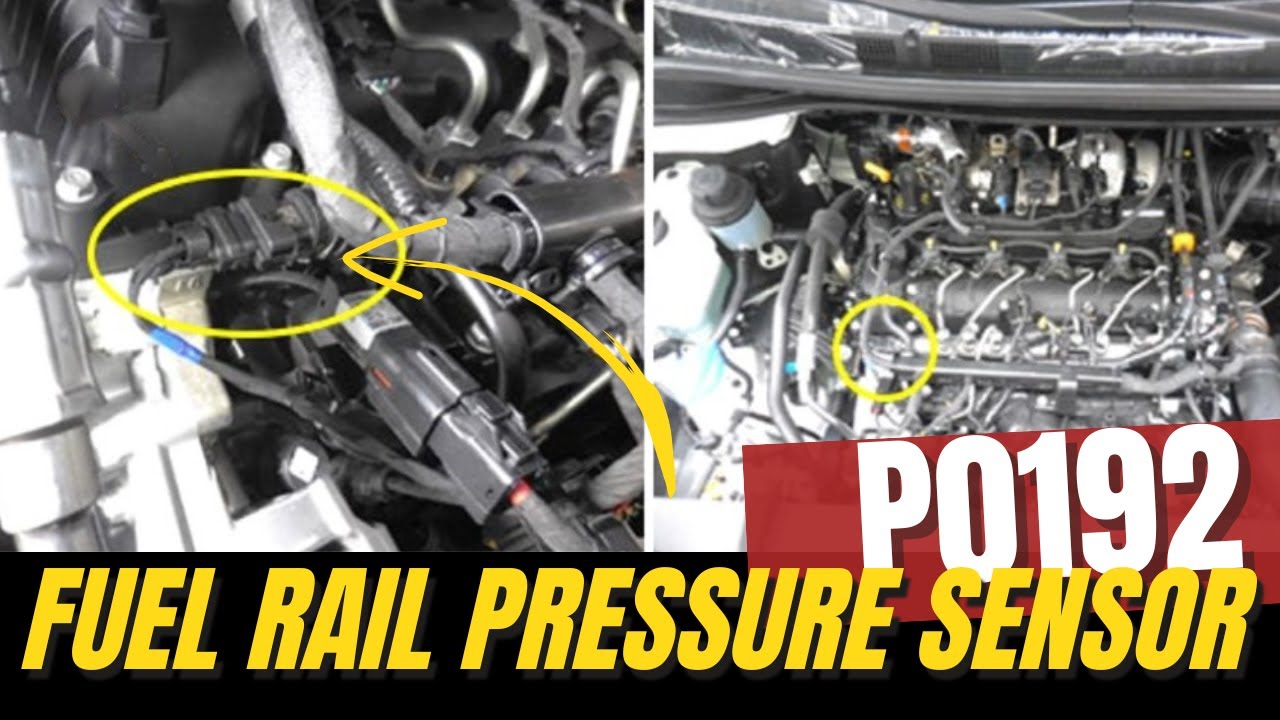

- Fuel Rail: A manifold that distributes fuel to the injectors.

- Fuel Injectors: Electrically controlled valves that spray fuel into the intake manifold or directly into the cylinder (in direct injection systems).

- Fuel Pressure Regulator: Maintains a constant fuel pressure in the fuel rail, typically by bleeding off excess fuel back to the tank through a return line. Some newer systems are "returnless" and regulate pressure at the fuel pump itself.

The pressure within the fuel rail, usually around 40-60 PSI (pounds per square inch) depending on the vehicle, ensures that the injectors can deliver a precise amount of fuel when they are activated. However, this pressure remains even when the engine is off, creating a potential hazard during maintenance.

Technical Breakdown: How to Release Fuel Pressure

There are several methods for releasing fuel pressure, each with its own advantages and disadvantages. We'll focus on the safest and most commonly used techniques:

1. The Schrader Valve Method

Many fuel rails are equipped with a Schrader valve, similar to the valve on a tire. This provides a convenient point to bleed off fuel pressure. Here’s how to use it:

- Safety First: Wear safety glasses and gloves. Work in a well-ventilated area away from any sources of ignition (open flames, sparks, etc.). Keep a fire extinguisher nearby just in case.

- Locate the Schrader Valve: It's usually found on the fuel rail, often covered by a small plastic cap. Consult your vehicle's service manual if you're unsure of its location.

- Prepare a Fuel-Safe Container: You'll need a container to catch the fuel. A small metal can or a fuel-resistant plastic container is ideal. Have some rags handy to absorb any spills.

- Attach a Bleed Hose (Recommended): Ideally, use a fuel pressure test kit with a bleed hose. Connect the hose to the Schrader valve and route the other end into your container. This provides a controlled way to release the fuel.

- Release the Pressure: If using a bleed hose, slowly open the valve on the hose. If not, carefully depress the Schrader valve's core using a small screwdriver or a valve core removal tool. Do this in short bursts, allowing the pressure to release gradually. Be prepared for a fuel spray, even if you're being careful.

- Verify Zero Pressure: Once the fuel flow stops, double-check that the pressure is indeed released. You can do this by gently tapping the Schrader valve with the screwdriver. If no fuel comes out, you're good to go.

- Clean Up: Properly dispose of the collected fuel. Wipe up any spills immediately.

2. The Fuel Pump Relay/Fuse Method

This method involves running the engine until it stalls due to lack of fuel, effectively depleting the pressure in the system. While seemingly simple, it carries some risks and requires careful execution.

- Locate the Fuel Pump Relay or Fuse: Consult your vehicle's service manual to identify the correct relay or fuse.

- Start the Engine: Let the engine run at idle.

- Remove the Relay/Fuse: Once the engine is running, carefully remove the fuel pump relay or fuse. The engine will likely sputter and eventually stall.

- Attempt to Restart: Crank the engine a few times to ensure that any remaining fuel in the rail is used up.

- Replace the Relay/Fuse: Once you are confident that the pressure is released, replace the relay or fuse.

Important Considerations for the Relay/Fuse Method:

- This method may not completely eliminate all pressure, especially in newer vehicles with sophisticated fuel systems.

- Running the fuel pump dry can potentially damage it. Avoid prolonged cranking after the engine stalls.

- This method can trigger diagnostic trouble codes (DTCs) that you'll need to clear with an OBD-II scanner.

3. The Injector Removal Method (Use with Extreme Caution)

This method involves carefully disconnecting a fuel injector and allowing the fuel to drain out. This is generally not recommended unless absolutely necessary, as it's the most prone to causing fuel spills and potential damage to the injectors.

Only attempt this method if the other two are not possible and you have extensive experience working on fuel systems.

- Safety First: Follow all the safety precautions mentioned earlier.

- Disconnect the Injector Connector: Unplug the electrical connector from one of the fuel injectors.

- Carefully Remove the Injector: Gently pry the injector out of the fuel rail and intake manifold. Be prepared for fuel to spray out. Have rags ready to absorb the fuel.

- Collect the Fuel: Direct the injector into a fuel-safe container and allow the fuel to drain.

- Reinstall the Injector: Once the fuel flow stops, carefully reinstall the injector and reconnect the electrical connector.

Common Issues and Maintenance Concerns

- Stuck Schrader Valve: The Schrader valve can sometimes become corroded or stuck, making it difficult to release pressure. Applying a small amount of penetrating oil may help. If it's severely damaged, the valve core may need to be replaced.

- Fuel Leaks: Always inspect fuel lines and connections for leaks after working on the fuel system. Replace any damaged or deteriorated components.

- Diagnostic Trouble Codes (DTCs): Removing the fuel pump relay or fuse can trigger DTCs related to fuel pressure or fuel pump performance. Use an OBD-II scanner to clear these codes after the repair.

- Fuel Contamination: When working on the fuel system, be careful not to introduce any contaminants (dirt, debris, etc.) into the fuel lines or injectors.

Do's and Don'ts / Best Practices

- DO prioritize safety. Wear safety glasses and gloves, work in a well-ventilated area, and keep a fire extinguisher handy.

- DO disconnect the negative battery cable before working on the fuel system to prevent accidental sparking.

- DO use fuel-safe containers and hoses when handling fuel.

- DO dispose of used fuel properly according to local regulations.

- DO consult your vehicle's service manual for specific instructions and safety precautions.

- DON'T work on the fuel system near open flames, sparks, or other sources of ignition.

- DON'T smoke while working on the fuel system.

- DON'T use excessive force when removing or installing fuel system components.

- DON'T reuse old fuel lines or fittings if they are cracked, damaged, or corroded.

- DON'T rely solely on the fuel pump relay/fuse method for complete pressure relief. Always double-check with the Schrader valve (if available) to ensure the system is fully depressurized.

Conclusion

Releasing fuel pressure is an essential step for safe and effective fuel system maintenance and repair. By understanding the principles involved and following the proper procedures, you can confidently depressurize the fuel rail and avoid potential hazards. The Schrader valve method is generally the safest and most recommended approach. Always prioritize safety, and if you're unsure about any aspect of the process, consult a qualified mechanic. Remember, taking your time and paying attention to detail will ensure a successful outcome and prevent costly mistakes.