How To Remove A Stuck Caliper Bolt

Ah, the stuck caliper bolt. The bane of many a home mechanic's existence. What starts as a simple brake job can quickly devolve into a frustrating battle against corrosion, thread damage, and sheer stubbornness. But fear not! While a stuck caliper bolt can be a challenge, understanding why it happens and employing the right techniques can significantly increase your chances of success. This article will delve into the mechanics of the caliper assembly, explore the common causes of seized bolts, and provide a step-by-step guide to freeing them, all while offering insights learned from real-world experience.

The Scenario: Brakes Gone Bad

Imagine this: You're finally tackling that overdue brake job. New rotors, new pads, a fresh bottle of brake fluid – you're ready to go. You confidently reach for your wrench to loosen the caliper bolts... and nothing. You apply more force. Still nothing. Panic starts to set in. You're stuck. This scenario is surprisingly common. It's not just about brute strength; it's about understanding the forces at play and employing the right leverage and techniques.

Think of it like trying to open a tightly sealed jar. Simply applying downward pressure often won't work. You might need to tap the lid, apply heat, or use a specialized jar opener to break the seal. A stuck caliper bolt is similar – you need to employ strategies that address the root cause of the problem.

Dissecting the Brake Caliper Assembly

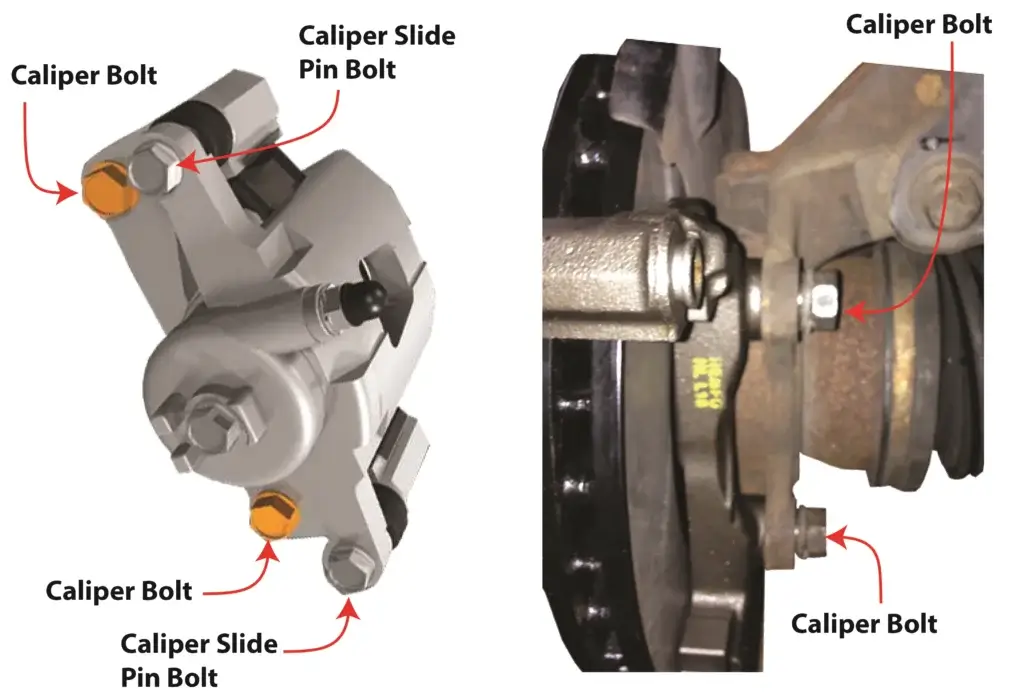

To effectively deal with a stuck bolt, we need to understand how the caliper assembly works. The brake caliper, usually made of cast iron or aluminum, houses the brake pads and pistons. When you press the brake pedal, hydraulic pressure forces the pistons to push the brake pads against the rotor, creating friction and slowing the vehicle. The caliper itself is typically attached to the steering knuckle via two bolts – the ones that are currently causing you grief.

These bolts usually thread into a bracket that is bolted to the knuckle. The caliper either slides on these bolts (in a floating caliper design) or is fixed in place (in a fixed caliper design). Floating calipers are far more common in passenger vehicles. The critical point is that these bolts are constantly exposed to harsh conditions: water, salt, road grime, and extreme temperature variations. This is a recipe for corrosion and seizing.

Here's a breakdown of the components and their roles:

- Caliper Bolts: Typically high-strength steel bolts that secure the caliper to the bracket.

- Caliper Bracket: A metal bracket bolted to the steering knuckle, providing a mounting point for the caliper.

- Slide Pins (for Floating Calipers): These pins allow the caliper to slide freely, ensuring even pad wear. These are often a source of binding themselves.

- Brake Pads: Friction material that presses against the rotor to slow the vehicle.

- Rotor: A metal disc that rotates with the wheel and provides a friction surface for the brake pads.

The Culprits: Why Caliper Bolts Get Stuck

Several factors contribute to the misery of stuck caliper bolts:

- Corrosion: This is the primary offender. The constant exposure to moisture, salt, and road chemicals creates rust and corrosion between the bolt threads and the caliper bracket. This corrosion effectively welds the bolt in place.

- Thread Damage: Over-tightening during previous brake jobs can damage the threads, making removal difficult. Cross-threading is another common culprit.

- Lack of Lubrication: Caliper bolts and slide pins (where applicable) should be lubricated with a high-temperature brake lubricant during installation. Neglecting this allows corrosion to take hold more easily.

- Galvanic Corrosion: If the bolt and caliper bracket are made of dissimilar metals (e.g., steel bolt in an aluminum bracket), galvanic corrosion can occur, accelerating the corrosion process.

- Physical Damage: In rare cases, physical damage from road debris can deform the bolt or bracket, making removal difficult.

The Arsenal: Tools and Techniques

Now, let's get to the solution. Here's a breakdown of tools and techniques to combat a stuck caliper bolt:

1. Penetrating Oil: Your First Line of Defense

Apply a high-quality penetrating oil (such as PB Blaster, Liquid Wrench, or Kroil) liberally to the bolt head and the area where the bolt threads into the bracket. Let it soak for at least 15-30 minutes, or even overnight for severely stuck bolts. Reapply periodically during the soaking period. The penetrating oil works by seeping into the threads and breaking down the corrosion.

Pro: Relatively inexpensive and easy to apply.

Con: May not be effective for severely corroded bolts.

2. The Right Wrench and Leverage

Use the correct size wrench or socket for the bolt head. A properly fitting tool is essential to avoid stripping the bolt head. Use a six-point socket or wrench whenever possible, as it provides a better grip than a 12-point tool. If possible, use a breaker bar to increase leverage. A longer breaker bar allows you to apply more torque without excessive force. Avoid using excessive force initially, as this can damage the bolt head or bracket. Apply steady, controlled pressure.

Pro: Increased leverage can break the bolt free.

Con: Can be challenging in tight spaces.

3. Heat: The Corrosion Buster

Applying heat to the caliper bracket can help to expand the metal and break the corrosion bond. Use a propane torch or heat gun to heat the area around the bolt head. Be careful not to overheat the brake line or other nearby components. After heating, immediately try to loosen the bolt while the metal is still hot. This is often the most effective method, but it's crucial to exercise caution.

Pro: Highly effective for breaking corrosion bonds.

Con: Risk of damaging surrounding components, fire hazard if not careful.

4. Impact Wrench: The Vibration Solution

An impact wrench delivers short, powerful bursts of torque, which can help to break the bolt free without stripping the head. Use a socket that fits snugly on the bolt head. The vibration from the impact wrench can help to loosen the corrosion.

Pro: Can deliver high torque without excessive force.

Con: Requires an air compressor or battery-powered impact wrench.

5. Hammering Technique: Shock and Awe

Sometimes, a well-placed hammer blow can help to break the corrosion. Use a hammer and punch to strike the bolt head sharply. The impact can help to loosen the corrosion bond. Be careful not to damage the bolt head or surrounding components.

Pro: Can be effective in breaking stubborn corrosion.

Con: Risk of damaging the bolt head or surrounding components.

6. Bolt Extractor: The Last Resort

If the bolt head is stripped or severely damaged, you may need to use a bolt extractor. These tools are designed to grip damaged bolt heads and allow you to remove them. Follow the manufacturer's instructions for using the bolt extractor. There are various types, including spiral flute extractors and external extractors that grip the outside of the bolt head.

Pro: Can remove severely damaged bolts.

Con: Can be expensive and may not work in all cases.

7. Drilling and Tapping: The Nuclear Option

As a very last resort, you can drill out the bolt. This is a delicate procedure that requires precision and care. Start by center-punching the bolt head and drilling a pilot hole. Gradually increase the drill bit size until you can remove the remaining bolt material. After drilling, you may need to tap new threads into the caliper bracket. This is best left to experienced mechanics.

Pro: Can remove even the most stubborn bolts.

Con: High risk of damaging the caliper bracket, requires specialized tools and skills.

Real-World Insights and Recommendations

Based on years of experience wrenching on cars, here are some additional tips and insights:

- Prevention is Key: Always use a high-temperature brake lubricant on caliper bolts and slide pins during installation. This will significantly reduce the risk of corrosion.

- Don't Over-Tighten: Caliper bolts should be tightened to the manufacturer's specified torque. Over-tightening can damage the threads and make removal difficult.

- Inspect Regularly: During brake jobs, inspect the caliper bolts for signs of corrosion or damage. Replace them if necessary.

- Use Quality Parts: Opt for high-quality replacement bolts made from corrosion-resistant materials.

- Consider a Torch (Carefully): When using a torch, avoid direct flame on the brake line or any rubber components. Use a heat shield if necessary.

- Patience is a Virtue: Don't rush the process. Applying too much force too quickly can strip the bolt head or damage the bracket. Take your time, apply penetrating oil liberally, and use the appropriate tools and techniques.

- Safety First: Always wear safety glasses and gloves when working on brakes.

Manufacturer Examples: Some manufacturers, like Honda and Toyota, are known for using particularly corrosion-prone brake hardware. Conversely, some European manufacturers, such as BMW and Audi, often use aluminum calipers which can be more susceptible to galvanic corrosion if the incorrect hardware is used.

Pro Tip: A trick some mechanics use is to tighten the bolt slightly before attempting to loosen it. This can sometimes break the corrosion bond and make removal easier.

Wrapping Up: Victory Over the Stuck Bolt

Dealing with a stuck caliper bolt can be frustrating, but by understanding the underlying causes and employing the right tools and techniques, you can significantly increase your chances of success. Remember to start with the least invasive methods (penetrating oil, proper leverage) and gradually escalate as needed. And always prioritize safety. With patience, persistence, and a little bit of ingenuity, you can conquer even the most stubborn caliper bolt and get back to enjoying your ride.