How To Remove Broken Stud From Wheel

Dealing with a broken wheel stud can be a frustrating and potentially dangerous situation. A wheel stud, also known as a lug stud, is the threaded fastener that secures the wheel to the vehicle's hub. If one breaks, it compromises the safety and stability of your wheel, making it crucial to address the problem promptly and correctly. This article will walk you through the process of diagnosing a broken wheel stud, understanding the cause, and, most importantly, how to remove and replace it.

Understanding the Problem: Broken Wheel Studs

The problem is straightforward: a wheel stud is broken. This prevents you from properly and safely securing your wheel. Driving with a broken wheel stud is extremely dangerous and should be avoided at all costs. The remaining studs are forced to bear more load than they are designed for, potentially leading to further stud failure and, ultimately, wheel detachment. Replacing a broken stud is vital for ensuring your wheel is securely fastened and your vehicle is safe to operate. While it might seem like a minor issue, it can have serious consequences if left unaddressed.

Symptoms of a Broken Wheel Stud

Identifying a broken wheel stud early can prevent further damage. Here are some common symptoms to look out for:

- Missing Lug Nut: This is the most obvious sign. If you notice a lug nut is missing and the stud is broken off at the hub, it's a clear indicator.

- Difficulty Tightening Lug Nuts: If you find it difficult or impossible to tighten a lug nut on a particular stud, even with the correct torque, the stud may be damaged or broken. It might feel stripped or cross-threaded.

- Uneven Wheel Vibration: While vibration can be caused by many things (unbalanced tires, suspension issues), a broken stud can contribute to an uneven vibration, especially at higher speeds. This is because the wheel is not properly secured and can wobble slightly.

- Clicking or Ticking Noise: You might hear a clicking or ticking noise coming from the wheel area, particularly at low speeds. This can be caused by the wheel shifting slightly due to the broken stud.

- Visually Broken Stud: Inspect each wheel stud carefully. Look for any signs of cracks, bends, or breaks. Even a hairline crack can indicate a compromised stud.

Root Causes of Wheel Stud Failure

Understanding why wheel studs break can help prevent future occurrences. Several factors can contribute to their failure:

- Overtightening Lug Nuts: This is one of the most common causes. Over-torquing stretches and weakens the stud, making it more susceptible to breakage. Always use a torque wrench and the manufacturer's specified torque settings.

- Improper Lug Nut Torque: Conversely, under-torquing lug nuts can also cause problems. Loose lug nuts allow the wheel to move and vibrate, putting excessive stress on the studs.

- Cross-Threading Lug Nuts: Starting a lug nut at an angle can damage the threads on both the lug nut and the stud. This weakens the stud and can lead to breakage. Always start lug nuts by hand to ensure they are properly aligned.

- Corrosion and Rust: Rust and corrosion can weaken the metal of the stud over time, making it more prone to failure, especially in areas with harsh weather conditions or road salt.

- Impact Damage: Hitting a curb or pothole can subject the wheel and studs to significant impact forces, potentially causing them to break.

- Material Fatigue: Over time, the constant stress and strain on the wheel studs can lead to metal fatigue, making them weaker and more likely to break.

- Using Incorrect Lug Nuts: Using lug nuts that are not compatible with the wheel or studs can cause improper seating and uneven pressure, leading to stud failure.

Consequences of Ignoring a Broken Wheel Stud

Ignoring a broken wheel stud can have severe consequences. The remaining studs will be forced to carry a greater load, increasing their risk of failure. This can lead to:

- Wheel Detachment: The most dangerous consequence is the complete detachment of the wheel while driving. This can cause a loss of control, leading to an accident, injury, or even death.

- Damage to Brake Components: A loose or detached wheel can damage brake lines, rotors, calipers, and other brake components, resulting in costly repairs.

- Damage to Suspension Components: A wobbly or detached wheel can also damage suspension components, such as control arms, struts, and ball joints.

- Further Stud Failure: As mentioned, the remaining studs will be under increased stress, making them more likely to break.

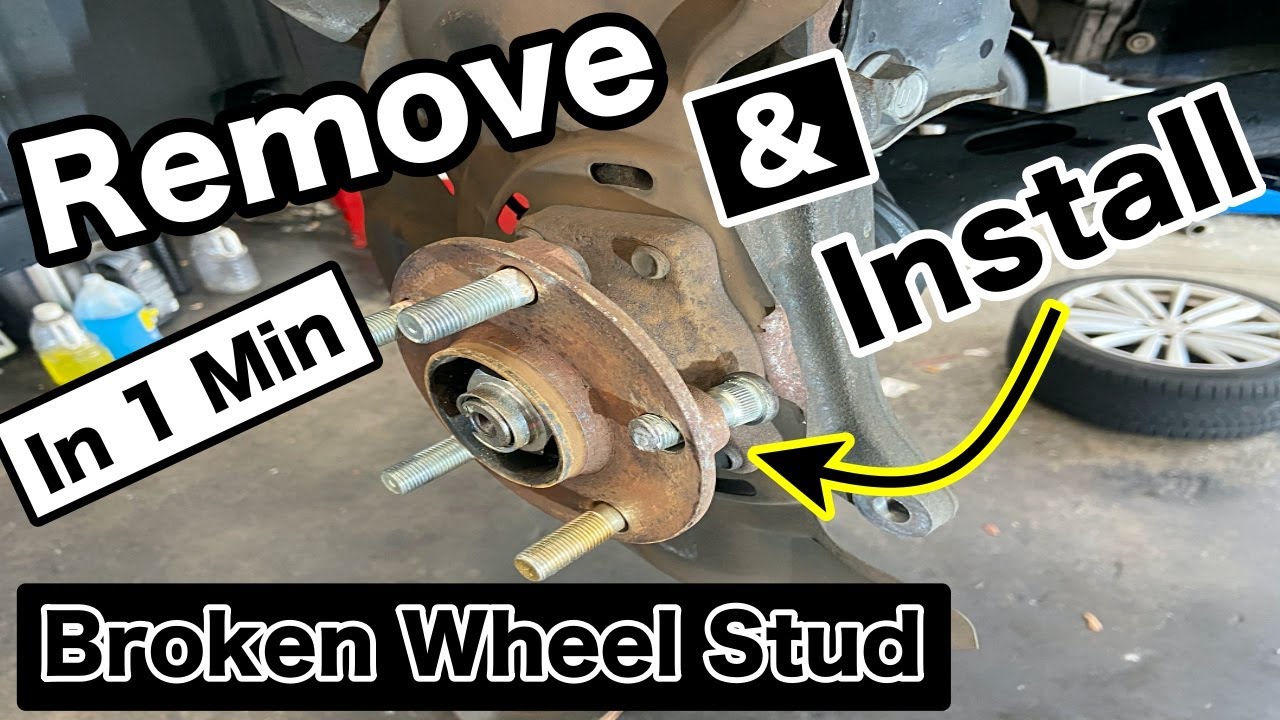

Recommended Fixes: Replacing the Broken Wheel Stud

The only effective solution is to replace the broken wheel stud. This is a relatively straightforward repair that can often be done at home with the right tools and knowledge. However, if you're not comfortable working on your vehicle, it's best to take it to a qualified mechanic.

Here's a general overview of the replacement process:

- Gather Your Tools and Materials:

- New wheel stud (make sure it's the correct size and thread pitch for your vehicle)

- Lug wrench

- Jack and jack stands

- Wheel chocks

- Hammer

- Punch or drift pin

- Torque wrench

- Penetrating oil (optional, but helpful for stubborn studs)

- Gloves and safety glasses

- Safety First: Park the vehicle on a level surface, engage the parking brake, and chock the wheels opposite the one you're working on.

- Loosen Lug Nuts: Loosen the lug nuts on the affected wheel. Do not remove them completely at this stage.

- Raise the Vehicle: Use the jack to raise the vehicle and securely support it with jack stands. Never work under a vehicle supported only by a jack.

- Remove the Wheel: Finish removing the lug nuts and carefully remove the wheel.

- Remove Brake Caliper and Rotor (If Necessary): In some cases, you may need to remove the brake caliper and rotor to access the wheel stud. This will depend on the design of your vehicle. If removal is needed, carefully disconnect the brake caliper, being mindful not to damage the brake line. Secure the caliper out of the way. Then, remove the rotor.

- Remove the Broken Stud: This is often the trickiest part. Spray the broken stud with penetrating oil and let it soak for a few minutes. Use a hammer and punch or drift pin to drive the stud out from the back side of the hub. You may need to use some force, but be careful not to damage the hub or wheel bearing. Sometimes the stud is very stubborn and may require heat. Be careful with heat around brake lines and other components.

- Install the New Stud: Insert the new wheel stud from the back side of the hub. There are several ways to seat the new stud:

- Using a Lug Nut and Washers: Place a stack of washers over the new stud and then thread a lug nut onto it. Tighten the lug nut to pull the stud into the hub. Ensure the stud sits flush against the hub flange. Be very careful not to overtighten the lug nut, as this can damage the stud or hub.

- Using a Ball Joint Press: A ball joint press provides even pressure and is the preferred method if available. Follow the tool's instructions for pressing the stud into the hub.

- Hammering: While not ideal, you can carefully tap the stud into place with a hammer. Use a socket or metal block to protect the stud threads. This method requires patience and precision to avoid damaging the stud or hub.

- Reinstall Brake Rotor and Caliper (If Removed): If you removed the brake caliper and rotor, reinstall them in the reverse order of removal. Be sure to properly torque the caliper bolts.

- Reinstall the Wheel: Carefully reinstall the wheel, ensuring it is flush against the hub.

- Tighten Lug Nuts: Hand-tighten the lug nuts in a star pattern.

- Lower the Vehicle: Lower the vehicle back to the ground.

- Torque Lug Nuts: Use a torque wrench to tighten the lug nuts to the manufacturer's specified torque settings. Again, tighten them in a star pattern. This is a crucial step to ensure the wheel is properly secured.

- Double-Check: After driving a short distance (50-100 miles), re-torque the lug nuts to ensure they haven't loosened.

Cost Estimates and Shop Advice

The cost of replacing a broken wheel stud can vary depending on the vehicle and whether you choose to do it yourself or have a mechanic do it.

- DIY: The cost of a new wheel stud is typically between $5 and $20. If you already have the necessary tools, the total cost will be minimal. However, if you need to purchase tools, the cost will be higher.

- Mechanic: A mechanic will typically charge between $50 and $150 per wheel stud, including parts and labor. The exact cost will depend on the complexity of the job and the mechanic's hourly rate. If the hub or wheel bearing is damaged, the cost will be significantly higher.

Shop Advice: If you're not comfortable working on your vehicle or if the stud is particularly difficult to remove, it's best to take it to a qualified mechanic. They have the experience and tools to do the job safely and efficiently. When choosing a mechanic, be sure to ask for a written estimate and check their reviews. Also, inquire about the brand of wheel studs they use. Opt for quality studs from reputable manufacturers.

TSBs and Common Failure Mileage: While there isn't typically a TSB (Technical Service Bulletin) specifically for broken wheel studs, they are a common issue, especially on vehicles that are frequently exposed to harsh conditions or that have been subjected to improper wheel installation practices. The mileage at which wheel studs fail can vary widely depending on driving habits, road conditions, and maintenance practices. However, it's a good idea to inspect your wheel studs periodically, especially if you live in an area with road salt or if you frequently tow heavy loads.

By understanding the causes, symptoms, and solutions for broken wheel studs, you can keep your vehicle safe and prevent potentially dangerous situations. Remember, safety always comes first!