How To Remove Rounded Brake Line Nut

Let's face it, rounding off a brake line nut is a rite of passage for almost every DIY mechanic. You're wrenching away, expecting a smooth loosening process, and then SNAP! The corners of the nut are gone, leaving you with a frustratingly circular piece of metal and a potentially dangerous situation. This article is dedicated to helping you navigate this problem, offering a range of techniques and advice to get that stubborn rounded brake line nut off without further damaging your brake lines.

Understanding the Brake System and Why You Need to Care

Before we dive into the how-to, let's quickly recap the importance of the brake system. This is arguably the most critical safety system in your vehicle. Its primary function is to decelerate or stop the vehicle by converting kinetic energy (motion) into thermal energy (heat) through friction. This friction is created between the brake pads and rotors (or brake shoes and drums in older systems) when you press the brake pedal.

Key Components and Their Roles:

- Master Cylinder: The heart of the hydraulic brake system. It converts the mechanical force from your foot on the brake pedal into hydraulic pressure.

- Brake Lines: These are the conduits through which brake fluid travels from the master cylinder to the brake calipers (or wheel cylinders). They are typically made of steel for strength and durability.

- Brake Calipers (or Wheel Cylinders): Calipers house the brake pads and use hydraulic pressure to clamp the pads against the rotors. Wheel cylinders perform a similar function for drum brakes, pushing the brake shoes outward against the drums.

- Brake Pads (or Shoes): The friction material that contacts the rotors or drums to slow the vehicle.

- Rotors (or Drums): The rotating surfaces that the brake pads or shoes press against.

- Brake Fluid: A specialized hydraulic fluid that transmits pressure throughout the system. It's *hygroscopic*, meaning it absorbs moisture from the air, which can lower its boiling point and reduce braking effectiveness.

- Brake Line Nuts (Fittings): These connect the various brake lines and components, ensuring a leak-proof seal. They're often referred to as *flare nuts* because they tighten against a flared end of the brake line.

Because the brake system relies on hydraulic pressure, any leaks are a serious problem. Brake line nuts must be properly tightened to prevent leaks, but they can also corrode and become incredibly difficult to loosen over time, making them prone to rounding.

Why Brake Line Nuts Round and What to Do About It

Brake line nuts are typically made of softer metals than the steel brake lines themselves. This makes them more susceptible to corrosion and damage. Several factors contribute to rounding:

- Corrosion: Rust and corrosion can weaken the nut and make it harder to grip.

- Over-Tightening: Previous attempts to tighten the nut too much can damage the corners.

- Using the Wrong Tools: Standard open-end wrenches are the worst offenders. They only grip the nut on two sides, concentrating force and increasing the risk of rounding.

- Age: Over time, the metal can simply weaken, making it more prone to damage.

Techniques for Removing Rounded Brake Line Nuts:

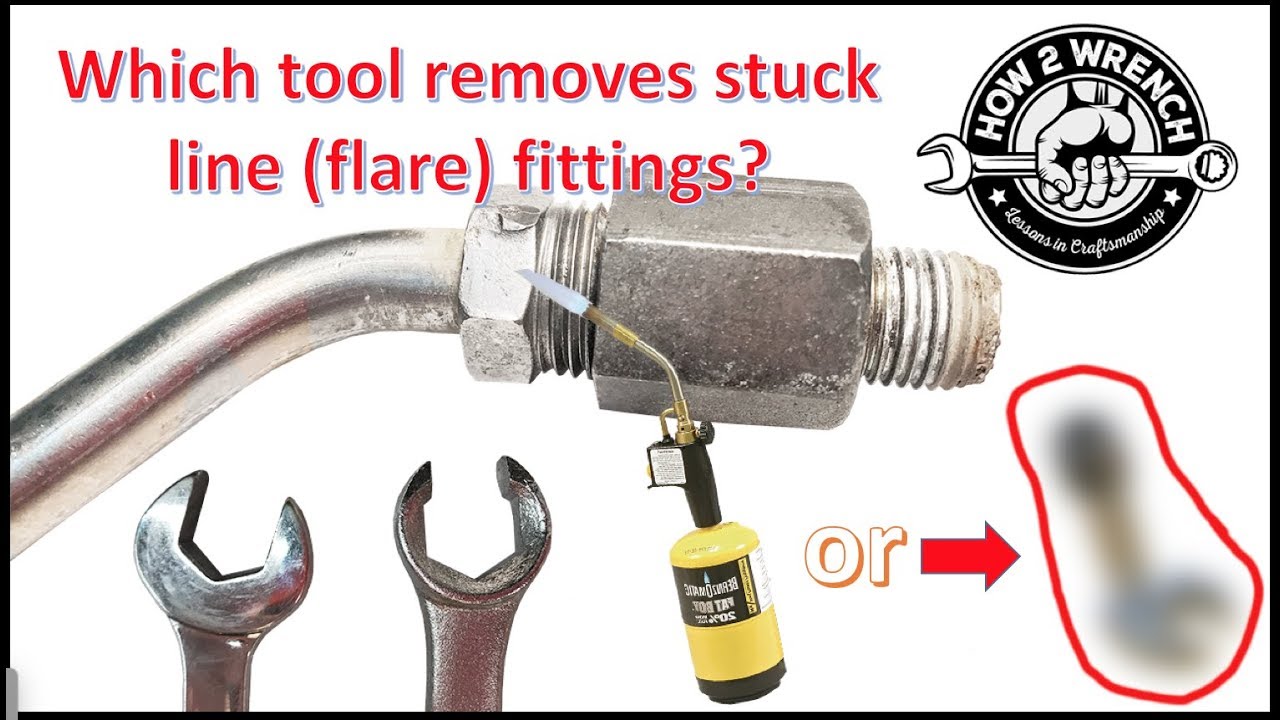

- The Flare Nut Wrench (Line Wrench): This is the first and most important tool in your arsenal. A flare nut wrench is a specialized wrench with a boxed end that has a small opening to slip over the brake line. This design provides much better contact with the nut than an open-end wrench, gripping on five or six sides instead of just two.

- Application: If the rounding is minimal, a good quality flare nut wrench might be all you need.

- Technique: Apply penetrating oil (like PB Blaster or Kroil) liberally and let it soak in for at least 15-30 minutes. Position the flare nut wrench securely on the nut, ensuring it's fully seated. Apply steady, even pressure. Avoid jerking motions, which can further damage the nut.

- Penetrating Oil and Heat:

- Application: When corrosion is a major factor.

- Technique: Apply penetrating oil repeatedly over several hours or even overnight. Heat can help the oil penetrate the corrosion. Use a propane or butane torch *cautiously*, focusing the heat on the nut itself, not the brake line. Avoid overheating, which can damage the rubber brake hoses or potentially ignite flammable fluids. After heating, try the flare nut wrench again.

- Rounded Nut Extractor Sockets: These are specialized sockets designed to grip rounded nuts and bolts. They typically have a reverse spiral or aggressive internal teeth that bite into the damaged nut.

- Application: When a flare nut wrench fails and the nut is significantly rounded.

- Technique: Choose the correct size extractor socket. Hammer it onto the rounded nut to ensure a tight grip. Use a ratchet or breaker bar to apply steady pressure to loosen the nut.

- Vise Grips (Locking Pliers): This is a last resort, as vise grips can further damage the nut and potentially the brake line.

- Application: Only use when other methods have failed and you're prepared to potentially replace the brake line.

- Technique: Adjust the vise grips to grip the nut as tightly as possible. Clamp down firmly and try to rock the nut back and forth slightly before attempting to fully loosen it. Be extremely careful not to crush the brake line.

- Nut Splitter: A nut splitter is a tool designed to crack the nut open.

- Application: When the nut is severely corroded and fused to the brake line.

- Technique: Position the nut splitter on the nut and tighten the bolt to split the nut. This requires replacing the brake line.

Common Issues and Maintenance Concerns

- Brake Fluid Leaks: After loosening or tightening brake line nuts, always check for leaks. Even a small leak can compromise your braking performance.

- Damaged Brake Lines: Be extremely careful not to bend or damage the brake lines during the removal process. Damaged lines can weaken and potentially burst under pressure.

- Bleeding the Brakes: After opening any part of the brake system, you'll need to bleed the brakes to remove air bubbles from the lines. Air in the lines can make the brake pedal feel spongy and reduce braking effectiveness.

- Brake Fluid Contamination: Always use the correct type of brake fluid for your vehicle (DOT 3, DOT 4, or DOT 5). Mixing different types of brake fluid can damage the brake system. Keep the brake fluid container sealed when not in use to prevent contamination.

Do's and Don'ts / Best Practices

Do's:

- Do use flare nut wrenches whenever possible.

- Do use penetrating oil liberally and allow it to soak in.

- Do apply heat cautiously and avoid overheating.

- Do use steady, even pressure when loosening the nut.

- Do clean and inspect the brake lines and fittings before reassembly.

- Do use new brake line nuts if the old ones are damaged or corroded.

- Do bleed the brakes after any work on the brake system.

- Do research the correct torque specifications for the brake line nuts.

- Do wear safety glasses to protect your eyes.

Don'ts:

- Don't use standard open-end wrenches on brake line nuts.

- Don't use excessive force, which can further damage the nut or brake line.

- Don't round off the nut more than it already is.

- Don't ignore signs of brake fluid leaks.

- Don't reuse old brake fluid.

- Don't let brake fluid come into contact with painted surfaces, as it can damage the paint.

- Don't work on the brake system if you are not comfortable with the procedures. Seek professional assistance if needed.

Conclusion

Removing a rounded brake line nut can be a frustrating experience, but with the right tools and techniques, it's often manageable for the experienced DIYer. Always start with a quality flare nut wrench and penetrating oil. If that fails, consider using a rounded nut extractor socket. Vise grips should be a last resort. If you're uncomfortable with any of these procedures, or if you're unsure about the safety of your brake system, it's best to seek the help of a qualified mechanic. Remember, your safety is paramount, and a properly functioning brake system is essential for safe driving.

Recommendation: Invest in a good set of flare nut wrenches. It's the single best investment you can make to prevent rounding brake line nuts in the first place.