How To Remove Stuck Caliper Bolt

Having trouble removing a stuck caliper bolt? You're not alone. This is a common frustration for DIY mechanics and even seasoned professionals. A seized caliper bolt can turn a simple brake job into a major headache. The inability to remove the caliper can prevent you from replacing brake pads, rotors, or even performing basic wheel maintenance. This guide will walk you through the likely causes, symptoms, and proven solutions to get that stubborn bolt moving.

Recognizing the Problem: Symptoms of a Stuck Caliper Bolt

Identifying the problem early is crucial. Here's a list of symptoms that indicate you're dealing with a stuck caliper bolt:

- Rounded Bolt Head: This is often the first sign. Applying too much force with the wrong size wrench can round off the bolt head, making it impossible to grip.

- Bolt Refuses to Turn: Even with a correctly sized wrench or socket, the bolt simply won't budge. You might feel excessive resistance, or the wrench may even start to bend.

- Snapping Sounds: Hearing a snapping sound when attempting to loosen the bolt can indicate corrosion or thread damage.

- Visible Corrosion: Obvious rust or corrosion around the bolt head and threads.

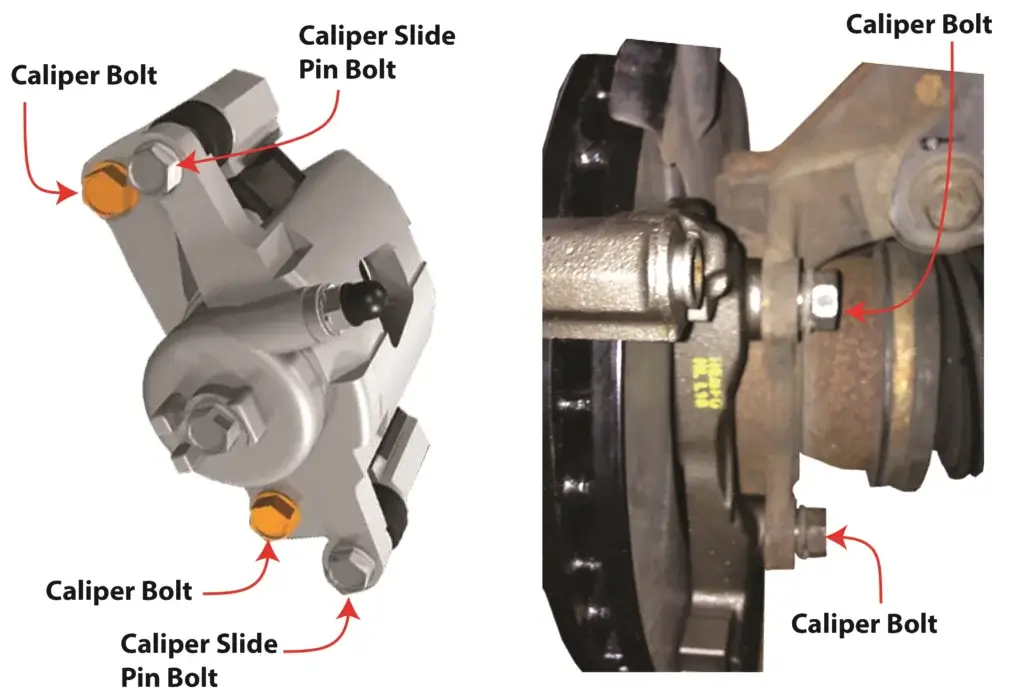

- Struggling to Remove Caliper: Even after removing what *should* be the bolts, you struggle to pull the caliper away from the rotor. This might be due to a remaining corroded bolt head or slider pins also being seized, which will exasperate your efforts.

Understanding the Root Cause: Why Caliper Bolts Get Stuck

Caliper bolts seize for several reasons, all related to the harsh environment they operate in. Here's a breakdown:

- Corrosion: This is the primary culprit. Brake systems are exposed to water, road salt (especially in winter climates), and brake dust, all of which contribute to rust and corrosion. This corrosion can fuse the bolt threads to the caliper bracket or the caliper itself.

- Lack of Lubrication: Caliper bolts are designed to be lightly lubricated to prevent seizing. Over time, this lubrication can dry out or become contaminated, increasing friction and the likelihood of the bolt getting stuck.

- Over-Tightening: Previous installations may have overtightened the bolts. This can stress the threads and make them more prone to seizing, especially when combined with corrosion. Overtightening can also damage the bolt itself, making it more susceptible to breaking.

- Thread Damage: Damaged threads on either the bolt or the caliper bracket can create friction and make removal difficult. This damage might be caused by improper installation, debris in the threads, or simply age and wear.

- Galvanic Corrosion: The bolt and caliper bracket are typically made of different metals. When these metals are in contact in the presence of an electrolyte (like water and salt), galvanic corrosion can occur, causing one metal to corrode faster than the other, essentially bonding the bolt to the bracket.

The Consequences of Ignoring a Stuck Caliper Bolt

Ignoring a stuck caliper bolt can lead to significant problems down the road. These problems include:

- Inability to Perform Brake Maintenance: As mentioned earlier, you won't be able to replace brake pads or rotors, leading to reduced braking performance and potential safety hazards. Worn brake pads can damage rotors, and worn rotors can compromise braking effectiveness.

- Damaged Brake Components: Attempts to force the bolt can damage the caliper bracket, the caliper itself, or even the brake lines. Replacing these components can be expensive.

- Increased Repair Costs: What starts as a simple brake job can quickly escalate into a more complex and costly repair involving replacing calipers, rotors, and even the entire brake system.

- Safety Hazards: Compromised brakes are a serious safety risk. Reduced braking performance increases stopping distances and the risk of accidents.

- Uneven Brake Wear: If one caliper is sticking due to a seized bolt or pin, the corresponding brake pads on that side will wear unevenly, further impacting braking performance.

Recommended Fixes: How to Remove That Stubborn Bolt

Here's a step-by-step guide to removing a stuck caliper bolt. Remember to always wear safety glasses and gloves.

- Preparation is Key: Gather the necessary tools. You'll need a properly sized wrench or socket (impact sockets are preferred), a breaker bar, penetrating oil, a hammer, a heat source (propane torch or heat gun), and potentially bolt extractors.

- Penetrating Oil: Generously apply penetrating oil to the bolt head and threads. Let it soak for at least 15-30 minutes, or even longer if possible. Reapply the oil periodically. This is often the most crucial step. Choose a high-quality penetrating oil specifically designed for loosening rusted bolts.

- Apply Heat: Use a propane torch or heat gun to heat the area around the bolt head. Heat expands the metal, which can help break the corrosion bond. Be careful not to overheat the surrounding components, especially rubber brake lines or seals. Apply heat in short bursts, checking frequently to avoid damage.

- The Breaker Bar: Attach a breaker bar to your wrench or socket. A breaker bar provides extra leverage, making it easier to break the bolt free. Apply steady, consistent pressure. Avoid jerky movements, which can snap the bolt.

- Hammering Technique: If the bolt still won't budge, try tapping the bolt head with a hammer. This can help break the corrosion and loosen the threads. Use a brass or rubber hammer to avoid damaging the bolt head. You can also try tapping the caliper bracket around the bolt to create vibrations that might help loosen it.

- Impact Wrench: An impact wrench can be very effective at removing stuck bolts. The rapid impacts help break the corrosion bond. Use an impact socket to avoid damaging the bolt head. If you choose this method start on a low setting and gradually increase the torque to prevent snapping the bolt.

- Bolt Extractor: If the bolt head is rounded off, you'll need to use a bolt extractor. There are several types of bolt extractors available, including spiral extractors and socket-type extractors. Follow the manufacturer's instructions carefully. Use bolt extractors as a last resort, as they can sometimes damage the threads further.

- Left-Handed Drill Bit (for Severely Damaged Bolts): In extreme cases, you may need to drill out the bolt. Start with a small left-handed drill bit and gradually increase the size. The left-handed rotation might actually unscrew the bolt as you drill.

- Re-threading or Replacement: Once the bolt is removed, inspect the threads in the caliper bracket. If they're damaged, you may need to re-thread them using a thread repair kit (e.g., Heli-Coil) or replace the caliper bracket. Always use new caliper bolts when reinstalling. Apply a thin coat of anti-seize compound to the bolt threads to prevent future seizing.

- Slider Pins Maintenance: While you have the caliper off, make sure to lubricate your slider pins with brake grease. These can also cause a sticking caliper and uneven pad wear.

Cost Estimates and Shop Advice

The cost of dealing with a stuck caliper bolt can vary depending on the severity of the problem and whether you choose to DIY or take it to a professional mechanic.

- DIY: If you're able to remove the bolt yourself, the cost will primarily be for penetrating oil, new caliper bolts, and potentially a bolt extractor if needed. This could range from $20 to $50. However, if you damage other components in the process, the cost could increase significantly.

- Professional Mechanic: A mechanic will typically charge an hourly rate for labor, plus the cost of parts (new bolts, caliper bracket, or caliper if necessary). The total cost could range from $100 to $500 or more, depending on the extent of the damage and the complexity of the repair.

Shop Advice: If you're not comfortable working on your brakes or if the bolt is severely stuck, it's best to take your vehicle to a professional mechanic. They have the tools and experience to safely remove the bolt and repair any damage. Make sure to get a quote beforehand and ask about the potential for additional costs if the problem is more complex than initially anticipated. It is advisable to replace caliper bolts in pairs. If one is stuck, the other is likely suffering from the same conditions. Also, discuss brake line inspection and replacement. If there is significant corrosion in the system, these may need replacement.

Credibility and Common Failure Points

While there isn't a single TSB (Technical Service Bulletin) specifically addressing stuck caliper bolts across all makes and models, many manufacturers issue TSBs related to brake component corrosion, which often includes recommendations for bolt inspection and lubrication. For example, some vehicles in rust belt states may have had campaigns to apply rust inhibitors to brake components. Checking forums related to your particular vehicle can also highlight common issues and potential solutions. The mileage at which caliper bolts start to seize varies greatly depending on factors like climate, driving conditions, and maintenance history. However, vehicles operating in regions with heavy salt usage during winter months, are more likely to experience this issue sooner than those in drier climates. Expect these issues more frequently after 5-7 years or 75,000 miles.

By understanding the causes, symptoms, and solutions outlined in this guide, you'll be well-equipped to tackle that stuck caliper bolt and get your brakes back in top working order. Good luck!