How To Remove The Fan Clutch

Let's talk about removing a fan clutch. If you're experiencing engine overheating, poor air conditioning performance at idle, or a loud, roaring noise from your engine bay, chances are your fan clutch is to blame. Replacing it is a pretty straightforward job that most intermediate DIYers can tackle with the right tools and a little patience. Saving money on labor costs is a big win, but understanding the system is key for a successful repair.

Background: The Engine Cooling System and Fan Clutch Function

Before we dive into the removal process, it's important to understand the role the fan clutch plays in your vehicle's cooling system. Internal combustion engines generate a lot of heat. To prevent catastrophic damage, this heat must be dissipated. The cooling system circulates coolant (a mixture of water and antifreeze) through the engine block and cylinder head(s), absorbing heat along the way. This heated coolant then flows to the radiator, where the heat is transferred to the air passing through the radiator fins.

The radiator relies on airflow to dissipate heat effectively. At higher speeds, the vehicle's forward motion forces enough air through the radiator. However, at low speeds or when idling, this natural airflow is insufficient. That's where the fan comes in. Most older and some newer vehicles use an engine-driven fan, connected to the engine via a fan clutch. Think of it as a variable speed drive mechanism for your cooling fan.

Technical Breakdown: How a Fan Clutch Works

A fan clutch is a thermostatic device designed to engage the fan more fully when the engine temperature rises and to disengage it (or allow it to slip) when the engine is cool. There are primarily two types of fan clutches:

- Thermal Fan Clutch: These are the most common type. They use a bimetallic spring located on the front of the clutch. This spring senses the air temperature coming off the radiator. When the air is hot (indicating a hot engine), the spring expands and allows a valve inside the clutch to open. This valve allows a viscous silicone fluid to flow from a reservoir into the working chamber. As the working chamber fills, the fan becomes more engaged, spinning closer to the speed of the engine and pulling more air through the radiator. When the air temperature drops, the bimetallic spring contracts, closing the valve and allowing the fluid to flow back into the reservoir. This reduces the fan speed and saves engine power.

- Non-Thermal Fan Clutch: These clutches don't have the bimetallic spring. They provide a more consistent amount of fan engagement, regardless of engine temperature. While simpler, they're less efficient because the fan is always pulling a significant amount of power from the engine.

The viscous fluid inside the thermal fan clutch is critical for its operation. Over time, this fluid can leak out or degrade, leading to reduced fan engagement and overheating issues. A slipping fan clutch will be evident by the fan rotating freely (without the engine turning) when the engine is off or spinning at significantly slower speeds than the engine RPM when the engine is running.

Common Issues and Maintenance Concerns

The fan clutch, being a mechanical device exposed to heat and vibration, is prone to failure. Common issues include:

- Fluid Leakage: This is the most common failure mode. The viscous fluid leaks out, reducing the clutch's ability to engage the fan. Look for oily residue or stains around the fan clutch and surrounding components.

- Bimetallic Spring Failure: The spring can become weakened or damaged, causing the clutch to either over-engage or under-engage the fan.

- Bearing Failure: The fan clutch has internal bearings that allow it to rotate smoothly. These bearings can wear out over time, causing noise, vibration, and eventual failure.

- Internal Valve Failure: The internal valve that regulates the flow of viscous fluid can become clogged or damaged, preventing the clutch from functioning properly.

Regular inspection of the fan clutch is recommended. Check for leaks, excessive play in the fan, and unusual noises. When replacing a fan clutch, always use a high-quality replacement part. Cheaper aftermarket clutches may not have the same performance or longevity as OEM or reputable brand alternatives.

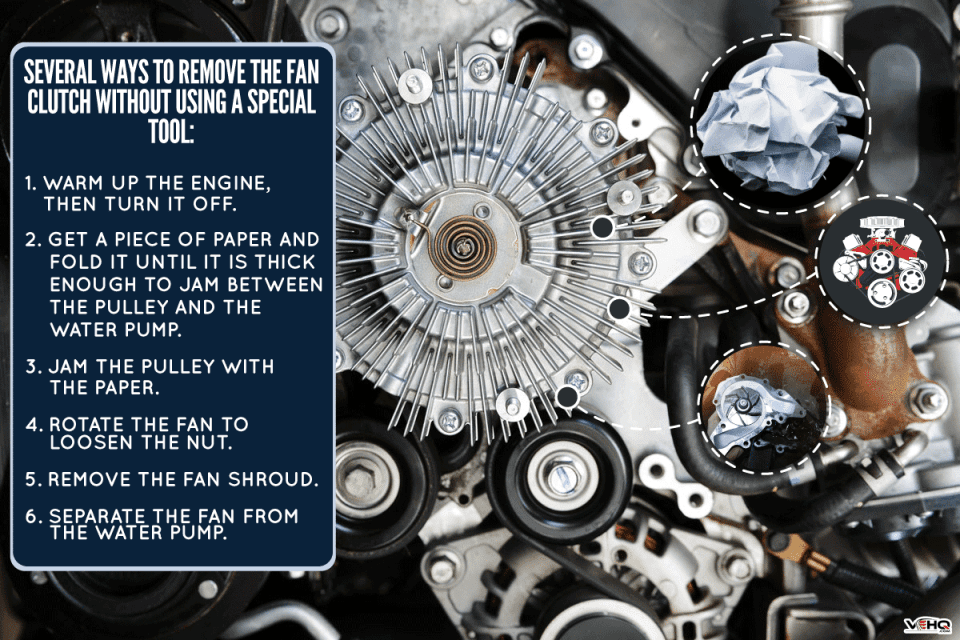

Removing the Fan Clutch: A Step-by-Step Guide

Now, let's get to the removal process. Safety first! Disconnect the negative battery terminal before starting any work on your vehicle.

Tools You'll Need:

- Fan Clutch Holding Tool: This is essential. It prevents the water pump pulley from rotating while you loosen the fan clutch nut. There are universal holding tools available, or you may need a specific tool for your vehicle.

- Fan Clutch Wrench: This is a large, thin wrench specifically designed to fit the fan clutch nut. The size varies depending on the vehicle (often 36mm, 40mm, or 48mm).

- Socket Set and Ratchet: For removing any necessary shrouds or other components.

- Screwdrivers: For removing any necessary shrouds or other components.

- Penetrating Oil: To help loosen the fan clutch nut if it's seized.

- Gloves and Safety Glasses: Protect yourself!

- Drain Pan (Optional): To catch any coolant that may spill.

Procedure:

- Preparation: Allow the engine to cool down completely before starting. Remove any engine covers or shrouds that obstruct access to the fan clutch.

- Apply Penetrating Oil: Spray penetrating oil onto the threads of the fan clutch nut. Let it soak for at least 15-20 minutes. This will make it much easier to loosen the nut.

- Secure the Water Pump Pulley: Insert the fan clutch holding tool to prevent the water pump pulley from rotating. The holding tool typically has pins or prongs that engage with the pulley bolts or holes.

- Loosen the Fan Clutch Nut: Using the fan clutch wrench, apply force to loosen the nut. Important: The fan clutch nut usually has a left-hand thread (reverse thread). This means you'll need to turn it clockwise to loosen it. Refer to your vehicle's service manual to confirm the correct direction. A sharp rap with a hammer on the end of the wrench can sometimes help break the nut free.

- Remove the Fan Clutch Assembly: Once the nut is loose, carefully remove the fan clutch assembly (fan and clutch together) from the water pump pulley. Be mindful of the fan blades, as they can be fragile.

- Inspect the Components: Once the fan clutch assembly is removed, inspect the water pump pulley for any signs of damage or wear. Also, check the condition of the fan blades for cracks or damage. Replace any damaged components as needed.

- Install the New Fan Clutch: Install the new fan clutch assembly in the reverse order of removal. Make sure the fan is oriented correctly. Tighten the fan clutch nut to the specified torque using a torque wrench. Refer to your vehicle's service manual for the correct torque specification. Over-tightening can damage the water pump bearings.

- Reinstall Components: Reinstall any engine covers or shrouds that were removed.

- Reconnect Battery: Reconnect the negative battery terminal.

- Test the System: Start the engine and let it idle for a few minutes. Monitor the engine temperature gauge to ensure that the engine is not overheating. Check for any leaks around the fan clutch area.

Do's and Don'ts / Best Practices

- DO use the correct tools. Trying to remove the fan clutch nut without the proper holding tool and wrench is likely to damage the water pump pulley or other components.

- DO apply penetrating oil to the nut. This can save you a lot of frustration.

- DO check the direction of the threads before applying force. Most are reverse-threaded.

- DO torque the fan clutch nut to the correct specification.

- DO inspect all related components, such as the water pump pulley and fan blades.

- DON'T use excessive force. If the nut is not budging, reapply penetrating oil and try again. You risk damaging components if you force it.

- DON'T use heat to loosen the nut. This can damage the fan clutch or surrounding components.

- DON'T forget to check for leaks after installation.

- DON'T reuse the old fan clutch nut if it shows signs of wear or damage.

Conclusion

Replacing a fan clutch is a manageable DIY project that can save you money and restore your vehicle's cooling system to proper working order. By understanding the function of the fan clutch, using the correct tools, and following the steps outlined above, you can successfully complete this repair. If you are unsure about any aspect of the process, consult a qualified mechanic. Always prioritize safety and refer to your vehicle's service manual for specific instructions and torque specifications.