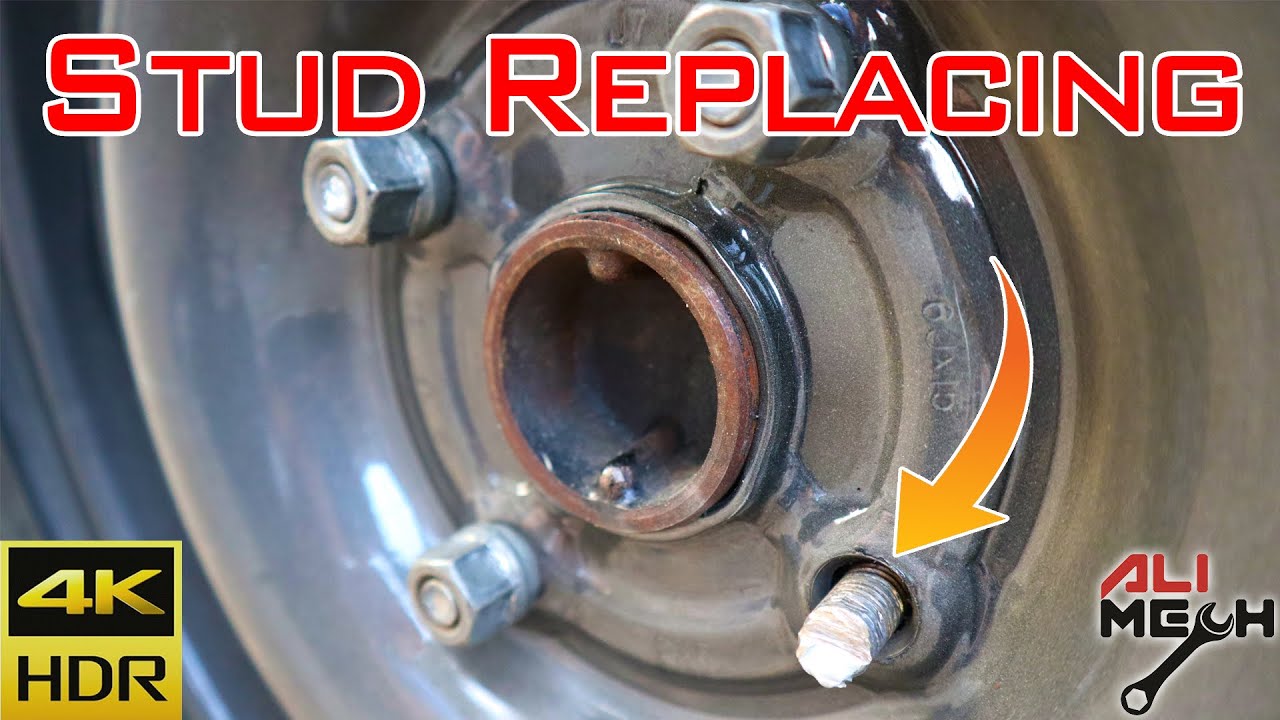

How To Replace A Broken Lug Nut Stud

A broken lug nut stud can be a frustrating and potentially dangerous problem. Your wheels are held securely to your vehicle by these vital components, and a compromised stud can lead to wheel loosening and, in the worst-case scenario, wheel detachment. Fortunately, replacing a broken lug nut stud is a repair that many confident DIYers can tackle at home with the right tools and a little patience. This article will guide you through the process.

Why Replacing a Broken Lug Nut Stud Matters

The importance of a functioning lug nut stud cannot be overstated. Each stud is designed to withstand significant force, ensuring the wheel remains firmly attached to the hub during acceleration, braking, and turning. When a stud breaks, it weakens the entire wheel mounting system. This can lead to several problems:

- Uneven Wheel Load: The remaining studs must bear a greater load than designed, increasing the risk of failure for those studs as well.

- Wheel Loosening: A broken stud compromises the clamping force, making it easier for lug nuts to loosen over time. This can cause vibrations and noise, serving as a warning sign.

- Wheel Detachment: If left unattended, a weakened wheel mounting system can lead to complete wheel detachment, resulting in a loss of vehicle control and a potentially serious accident.

- Damage to the Hub and Wheel: A loose wheel can vibrate against the hub and wheel, causing damage to both components. This can necessitate even more costly repairs.

Ignoring a broken lug nut stud is a gamble with your safety and the well-being of others on the road. Addressing the issue promptly is crucial.

How to Choose the Right Lug Nut Stud

Selecting the correct replacement lug nut stud is essential for a safe and effective repair. Here's what to consider:

1. Identification

Start by identifying the exact make, model, and year of your vehicle. This information is crucial for finding the right replacement part. You can usually find this information on your vehicle's registration, insurance card, or a sticker located on the driver's side doorjamb.

2. Thread Size and Pitch

The thread size and pitch are critical measurements. These measurements determine how the lug nut will thread onto the stud. Common thread sizes include 12mm x 1.5, 12mm x 1.25, 14mm x 1.5, and 1/2" x 20. You can typically find this information in your vehicle's owner's manual or by searching online parts catalogs specific to your vehicle. Alternatively, you can use a thread pitch gauge to measure the existing studs.

3. Stud Length

The stud length must be sufficient to securely hold the wheel. If the stud is too short, the lug nut won't have enough threads to grip. If it's too long, it may interfere with other components. Match the length of the new stud to the original stud. Consider the thickness of your wheels when choosing the length.

4. Knurl Diameter

The knurl is the textured portion of the stud that presses into the hub. The knurl diameter is critical for a secure fit. Using a stud with an incorrect knurl diameter can damage the hub or result in a loose stud. Use a caliper to measure the existing knurl diameter or consult your vehicle's parts catalog.

5. Material and Quality

Opt for high-quality lug nut studs made from durable materials like hardened steel. Avoid cheap, low-quality studs, as they are more prone to breakage. Consider purchasing studs from reputable brands known for their quality and reliability.

6. Where to Purchase

You can purchase replacement lug nut studs from several sources:

- Auto Parts Stores: Local auto parts stores are a convenient option, as you can often get advice from the staff and compare different brands.

- Online Retailers: Online retailers offer a wider selection and often lower prices. However, be sure to verify the part's compatibility with your vehicle before ordering.

- Dealerships: Dealerships can provide OEM (Original Equipment Manufacturer) parts, ensuring a perfect fit. However, they are often more expensive than other options.

Always double-check the part number and specifications before purchasing to ensure you're getting the right lug nut stud for your vehicle.

Replacing the Lug Nut Stud: A Step-by-Step Guide

Safety First: Before starting, ensure your vehicle is parked on a level surface, the parking brake is engaged, and the wheels are chocked to prevent rolling.

Tools You'll Need:

- New lug nut stud

- Lug wrench

- Jack and jack stands

- Hammer

- Punch or drift pin

- Wheel bearing grease (optional)

- Torque wrench

- Safety glasses

- Gloves

Step-by-Step Instructions:

- Loosen the Lug Nuts: Use the lug wrench to loosen the lug nuts on the wheel with the broken stud. Loosen them slightly, but don't remove them completely yet.

- Jack Up the Vehicle: Use the jack to lift the vehicle and securely support it with jack stands. Never work under a vehicle supported only by a jack.

- Remove the Wheel: Finish removing the lug nuts and carefully take the wheel off the vehicle.

- Access the Broken Stud: Depending on your vehicle's design, you may need to remove the brake caliper and rotor to access the back of the hub where the lug nut stud is located. Consult your vehicle's repair manual for specific instructions.

- Remove the Broken Stud:

- Method 1 (Hammer and Punch): Place the punch or drift pin against the back of the broken stud and use the hammer to carefully drive it out of the hub.

- Method 2 (Ball Joint Press): If the stud is particularly stubborn, a ball joint press can be used for controlled removal. This method is generally preferred, as it minimizes the risk of damaging the hub.

Be careful not to damage the wheel bearing or other components while removing the stud.

- Install the New Stud:

- Method 1 (Using Lug Nut and Impact Gun/Wrench): Place the new stud through the back of the hub. Place a few washers (about the thickness of the hub flange) over the stud. Then, using an old lug nut (one you don't care about damaging), thread it onto the new stud and use a impact gun or wrench to draw the new stud through the hub. The washers prevent the lug nut from bottoming out on the hub flange. It is important to add grease to the lug nut and stud to ensure it doesn't bind. Stop when the stud is fully seated and the stud head is flush with the hub flange.

- Method 2 (Ball Joint Press): If you have a ball joint press, it's the preferred method. Place the new stud through the back of the hub. Use the ball joint press, with the appropriate adapters, to press the new stud into place until it is fully seated.

Ensure the stud is fully seated and flush against the hub flange.

- Reinstall the Caliper and Rotor (if removed): Reinstall the brake caliper and rotor, following the instructions in your vehicle's repair manual.

- Reinstall the Wheel: Carefully mount the wheel back onto the hub.

- Install the Lug Nuts: Hand-tighten the lug nuts in a star pattern.

- Lower the Vehicle: Lower the vehicle until the wheel is just touching the ground.

- Torque the Lug Nuts: Use a torque wrench to tighten the lug nuts to the manufacturer's specified torque. Again, use a star pattern to ensure even pressure. You can find the proper torque specification in your vehicle's owner's manual or repair manual.

- Final Lowering: Fully lower the vehicle and remove the jack stands.

- Re-Torque: After driving a short distance (e.g., 50-100 miles), re-torque the lug nuts to ensure they remain properly tightened.

Real-World Owner Experiences

Many vehicle owners have successfully replaced broken lug nut studs themselves, saving money and gaining valuable experience. Common challenges include:

- Stubborn Studs: Removing a corroded or tightly seized stud can be difficult. Using penetrating oil and patience is key.

- Hub Damage: Carelessness during removal can damage the hub. Using the correct tools and techniques is essential.

- Incorrect Parts: Ordering the wrong lug nut stud is a common mistake. Double-checking the specifications before ordering is crucial.

Reading online forums and watching instructional videos can provide valuable insights and tips from other DIYers who have tackled this repair. Don't hesitate to ask questions and seek advice from experienced mechanics or online communities.

Frequently Asked Questions (FAQs)

Q: Can I drive with a broken lug nut stud?

A: It is strongly advised against driving with a broken lug nut stud. It compromises the safety of your wheel and can lead to further damage or a dangerous accident.

Q: How much does it cost to have a mechanic replace a lug nut stud?

A: The cost can vary depending on the vehicle and labor rates, but typically ranges from $50 to $150 per stud. This cost is generally lower than other auto repair jobs.

Q: Can I use an impact wrench to tighten lug nuts?

A: While an impact wrench can be used to tighten lug nuts, it's crucial to finish the job with a torque wrench to ensure they are tightened to the proper specification. Over-tightening can damage the studs or wheels, while under-tightening can lead to loosening.

Q: How often should I check my lug nuts?

A: It's recommended to check your lug nuts periodically, especially after tire rotations or any wheel service. A good practice is to check them every 5,000 to 10,000 miles or before long trips.

Q: What causes lug nut studs to break?

A: Common causes include over-tightening lug nuts, using the wrong lug nuts, corrosion, and fatigue over time.

Q: Is it safe to weld a lug nut stud?

A: No. Welding is not a safe or recommended method for repairing a broken lug nut stud. Welding can weaken the metal and create a brittle joint, which is likely to fail under stress. Always replace the stud with a new one.

Replacing a broken lug nut stud is a manageable task for many DIYers. By following these steps and taking the necessary precautions, you can restore the safety and integrity of your vehicle's wheel mounting system.