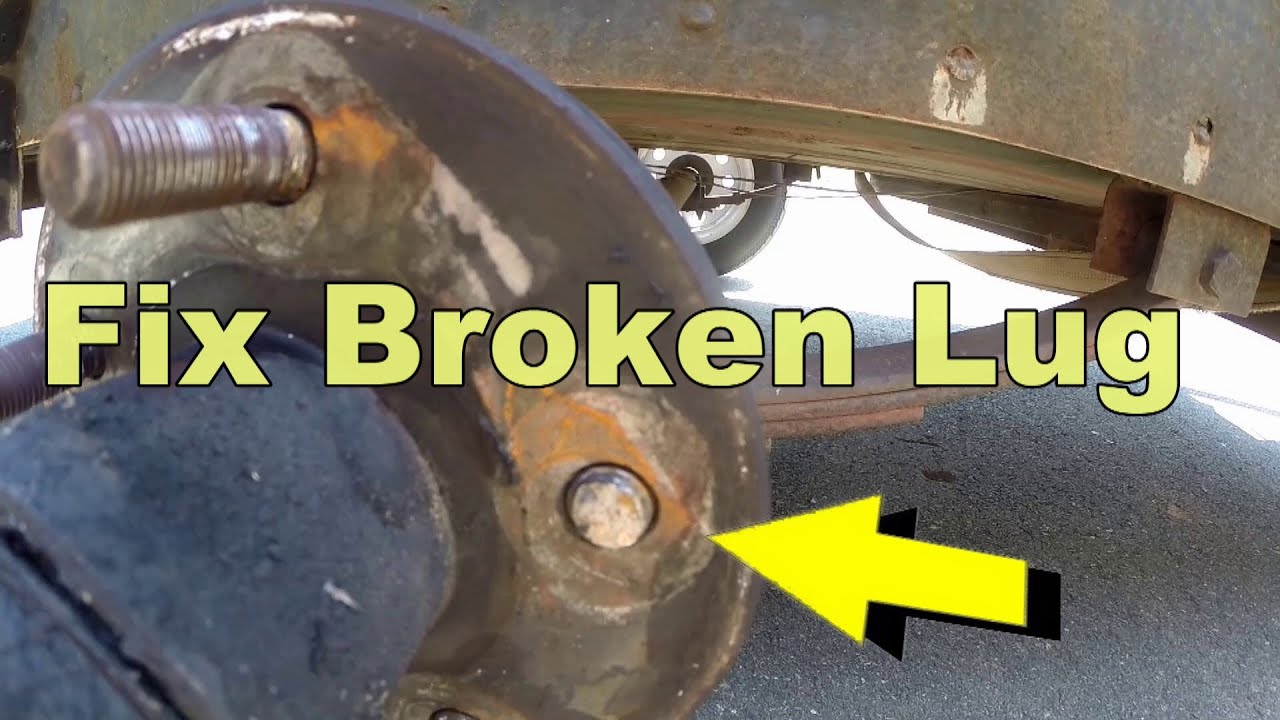

How To Replace A Lug Nut Bolt

Replacing a lug nut bolt might seem daunting, but it's a manageable DIY task that can save you money and time. This article provides a step-by-step guide to safely and effectively replace a lug nut bolt, ensuring your wheel is securely fastened and your vehicle remains safe to drive. We'll cover everything from identifying the correct replacement to executing the repair, all explained in a clear and easy-to-understand manner.

Why Replacing a Lug Nut Bolt Matters

The lug nuts and bolts are critical components that secure your vehicle's wheels to the hub. A damaged, stripped, or broken lug nut bolt can severely compromise the safety of your vehicle. Here's why replacing them is essential:

- Wheel Security: Damaged lug nut bolts can't properly grip the wheel, leading to loosening and potential wheel detachment while driving. This is an extremely dangerous scenario.

- Even Torque Distribution: Proper torque is crucial for wheel security. A damaged bolt can't maintain the correct torque, placing undue stress on other lug nuts and the wheel studs themselves.

- Vibration and Noise: Loose lug nuts, caused by damaged bolts, can cause vibrations and unusual noises from the wheel area, indicating a problem that needs immediate attention.

- Prevent Further Damage: Ignoring a damaged lug nut bolt can lead to damage to the wheel, hub, and potentially the brake rotor. Addressing the issue promptly can prevent more costly repairs down the line.

- Safety Inspection Failure: Many states include lug nut integrity as part of vehicle safety inspections. Damaged lug nuts can result in a failed inspection, preventing you from legally operating your vehicle.

Driving with a damaged lug nut bolt is not worth the risk. If you suspect a problem, inspect your lug nuts immediately and replace any that show signs of damage.

How to Choose the Right Replacement Lug Nut Bolt

Selecting the correct replacement lug nut bolt is crucial for a safe and effective repair. Using the wrong size or type can lead to further damage or failure. Here's a breakdown of the factors to consider:

1. Identify the Correct Size and Thread Pitch:

This is the most critical step. The size (diameter) and thread pitch of the lug nut bolt must match the original exactly. Here's how to determine this:

- Vehicle Owner's Manual: Your vehicle's owner's manual often provides the lug nut bolt specifications.

- Original Lug Nut: If you have an undamaged original lug nut, take it to an auto parts store. They can use a thread gauge to determine the size and pitch.

- Online Resources: Many online databases and parts lookup tools allow you to enter your vehicle's year, make, and model to find the correct lug nut bolt specifications.

- Visual Inspection: While less precise, you can visually compare the damaged bolt to a new one. However, this is not recommended for critical applications like lug nuts.

Common lug nut bolt sizes include: 12mm x 1.5, 12mm x 1.25, 14mm x 1.5, 14mm x 1.25. The first number represents the diameter of the bolt, and the second number represents the distance between the threads (thread pitch).

2. Material and Strength:

Lug nut bolts are typically made from steel. Ensure the replacement is made from a similar or higher-strength material. Look for bolts that meet or exceed OEM (Original Equipment Manufacturer) specifications.

3. Lug Nut Style:

There are different styles of lug nuts, including:

- Conical (Acorn): The most common type, with a tapered seat that centers the wheel on the hub.

- Mag (Flat-Faced): Often used with aftermarket wheels, featuring a flat face that presses against the wheel.

- Ball Seat (Rounded): Features a rounded seat that centers the wheel.

Ensure the replacement lug nut matches the style of the original lug nuts and the wheel design.

4. Coating and Finish:

Consider the coating or finish of the lug nut bolt. Chrome-plated bolts are aesthetically pleasing, but they can be more susceptible to corrosion. A black oxide or zinc coating offers better corrosion resistance.

5. Purchase from a Reputable Source:

Buy your replacement lug nut bolts from a reputable auto parts store or online retailer. This ensures you're getting a quality product that meets safety standards. Avoid purchasing cheap, generic lug nuts from unknown sources, as they may be made from inferior materials and could fail under stress.

Real-World Owner Experiences

Many drivers have encountered issues with lug nut bolts. Here are some common experiences and lessons learned:

- Stripped Threads: Overtightening lug nuts is a common cause of stripped threads. Always use a torque wrench and adhere to the recommended torque specifications.

- Corrosion: In regions with harsh winters and road salt, corrosion can weaken lug nut bolts over time. Regularly inspect your lug nuts for rust and corrosion.

- Incorrect Installation: Failing to properly seat the lug nuts on the wheel can lead to loosening and damage. Ensure the lug nuts are flush against the wheel before tightening.

- Impact Wrench Abuse: While convenient, impact wrenches can easily overtighten lug nuts. Use an impact wrench with caution and always double-check the torque with a torque wrench.

- Aftermarket Wheel Compatibility: Using the wrong lug nuts with aftermarket wheels is a common mistake. Ensure the lug nuts are compatible with the wheel's lug nut seat design.

These experiences highlight the importance of proper installation, maintenance, and choosing the correct replacement lug nut bolts. Taking the time to do it right can prevent potentially dangerous situations.

Step-by-Step Guide: How to Replace a Lug Nut Bolt

Here's a detailed guide to safely and effectively replace a lug nut bolt:

- Gather Your Tools and Materials:

- Replacement lug nut bolt (correct size and type)

- Lug wrench

- Torque wrench

- Jack and jack stands

- Wheel chocks

- Penetrating oil (optional, for removing stubborn nuts)

- Gloves

- Safety glasses

- Safety First:

- Park your vehicle on a level surface.

- Engage the parking brake.

- Place wheel chocks behind the wheels opposite the one you're working on.

- Wear safety glasses and gloves.

- Loosen the Lug Nuts:

Before lifting the vehicle, use the lug wrench to loosen the lug nuts on the affected wheel. Do not remove them completely. Loosen them only about 1/4 to 1/2 turn.

- Lift the Vehicle:

- Consult your vehicle's owner's manual for the correct jacking points.

- Place the jack under the designated jacking point and lift the vehicle until the wheel is off the ground.

- Secure the vehicle with jack stands placed under the frame near the jacking point. Never work under a vehicle supported only by a jack.

- Remove the Wheel:

Completely remove the loosened lug nuts and carefully pull the wheel off the hub. Set the wheel aside.

- Remove the Damaged Lug Nut Bolt:

This is the trickiest part. You might need specific tools, depending on whether the bolt is stripped, broken, or simply loose.

- If the bolt is stripped but still has some head left: Use a lug nut extractor socket. These sockets have a reverse spiral design that grips the stripped bolt head.

- If the bolt head is completely rounded: You might need to weld a new nut onto the rounded bolt head to get a grip, or consider professional help.

- If the bolt is broken: This is often the most difficult. If enough of the stud is protruding, you can try using a stud extractor. If not, you may need to remove the entire hub assembly and have a professional press out the broken stud.

- Replacing the entire hub assembly: In some cases, if the lug stud is severely damaged or corroded, it might be easier and safer to replace the entire hub assembly. This is a more involved repair but ensures all components are in good working order.

Important Safety Note: Removing a severely damaged or broken lug stud can be dangerous. If you're not comfortable with this process, it's best to seek professional assistance from a qualified mechanic.

- Install the New Lug Nut Bolt:

- Clean the area around the lug nut bolt hole on the hub.

- Apply a small amount of anti-seize compound to the threads of the new lug nut bolt (optional, but recommended).

- Carefully thread the new lug nut bolt into the hub. Ensure it's properly aligned and doesn't cross-thread.

- Reinstall the Wheel:

- Carefully align the wheel with the lug nut bolts on the hub.

- Push the wheel onto the hub until it's flush.

- Hand-tighten the lug nuts in a star pattern (opposite nuts) to ensure even pressure.

- Lower the Vehicle:

- Remove the jack stands.

- Slowly lower the vehicle until the wheel is on the ground.

- Torque the Lug Nuts:

- Using a torque wrench, tighten the lug nuts to the manufacturer's recommended torque specification (refer to your owner's manual).

- Tighten the lug nuts in a star pattern, in stages, to ensure even pressure.

- Double-Check:

- After driving a short distance (e.g., 50-100 miles), re-torque the lug nuts to ensure they haven't loosened.

- Regularly inspect your lug nuts for tightness and any signs of damage.

FAQs

Q: How much does it cost to replace a lug nut bolt?

A: The cost can vary depending on the vehicle and whether you do it yourself or hire a mechanic. The lug nut itself is inexpensive (a few dollars). If you replace it yourself, the cost is minimal. If you have a mechanic do it, labor charges will apply, potentially costing between $50 and $150 or more, especially if the stud is broken and requires hub removal.

Q: Can I drive with a missing lug nut?

A: No. Driving with a missing lug nut is extremely dangerous and not recommended. It can cause uneven stress on the remaining lug nuts, leading to their failure and potential wheel detachment. Get it fixed immediately.

Q: How often should I check my lug nuts?

A: It's a good practice to check your lug nuts after any wheel service, like tire rotations or brake repairs. Otherwise, checking them every 6 months or during regular vehicle maintenance is recommended.

Q: What happens if I overtighten my lug nuts?

A: Overtightening lug nuts can stretch or damage the threads on the bolt or stud, making them more likely to fail. It can also warp the brake rotor or damage the wheel. Always use a torque wrench and adhere to the recommended torque specifications.

Q: What if I can't remove the damaged lug nut bolt?

A: If you're struggling to remove the damaged lug nut bolt, don't force it. Seek professional help from a qualified mechanic. They have the tools and expertise to safely remove stubborn or broken lug nuts without damaging the vehicle.