How To Replace A Stabilizer Bar

Replacing a stabilizer bar, also known as a sway bar or anti-roll bar, is a repair that falls squarely within the capabilities of an experienced DIYer. While it might not be as simple as changing your oil, it's a task that can significantly improve your vehicle's handling and safety, and save you money compared to a professional mechanic's labor costs. This article will guide you through the process, providing the technical background, step-by-step instructions, and best practices to ensure a successful replacement.

Background: The Stabilizer Bar and Its Function

Before diving into the replacement process, let's understand the purpose of the stabilizer bar. Modern vehicles rely heavily on sophisticated suspension systems to provide a comfortable ride and responsive handling. A key component of this system is the stabilizer bar. It's a torsion spring, typically made of steel, that connects the left and right wheels through the vehicle's chassis. Its primary function is to reduce body roll during cornering. Without a stabilizer bar, the body of the vehicle would lean excessively in turns, negatively impacting handling and potentially leading to loss of control.

Technical Breakdown: How it Works

Imagine a car turning a corner to the left. The weight of the vehicle shifts to the right side, causing the right suspension to compress and the left suspension to extend. This difference in suspension travel is what causes body roll. The stabilizer bar resists this differential movement. As one side of the suspension compresses and the other extends, the stabilizer bar twists. This twisting action creates a restoring force that opposes the body roll, keeping the vehicle flatter and improving stability.

The effectiveness of the stabilizer bar is determined by its stiffness. A stiffer bar will provide greater resistance to body roll, resulting in flatter cornering and improved handling. However, an overly stiff bar can negatively impact ride quality, making the ride harsher and less comfortable on uneven surfaces. The stabilizer bar connects to the suspension through end links and bushings. The end links attach the bar to the suspension arms or struts, while the bushings mount the bar to the vehicle's frame or subframe. These components allow the stabilizer bar to move freely while still providing the necessary resistance to body roll.

Common Issues and Maintenance Concerns

Stabilizer bars themselves are generally robust and long-lasting. However, the components that connect them to the suspension are susceptible to wear and tear. Common issues include:

- Worn Bushings: Bushings are typically made of rubber or polyurethane and can deteriorate over time due to exposure to the elements and constant flexing. Worn bushings can cause clunking noises, especially when driving over bumps. They can also reduce the effectiveness of the stabilizer bar, leading to increased body roll.

- Damaged End Links: End links are subject to significant stress and can fail due to corrosion, impacts, or simply fatigue. Damaged end links can also cause clunking noises and negatively impact handling. Look for play in the joint of the end link.

- Bent or Broken Stabilizer Bar: While less common, stabilizer bars can be bent or broken in severe accidents or due to extreme off-road driving. A bent or broken bar will obviously require replacement.

- Corrosion: In regions with harsh winters and road salt, corrosion can weaken the stabilizer bar and its components, leading to premature failure.

Regular inspection of the stabilizer bar, bushings, and end links is crucial for maintaining optimal handling and safety. Listen for clunking noises, and visually inspect the components for signs of wear, damage, or corrosion. Replacing worn bushings and end links as needed can prevent more serious problems down the road.

Replacing the Stabilizer Bar: A Step-by-Step Guide

Here's a detailed guide to replacing a stabilizer bar. Always consult your vehicle's service manual for specific instructions and torque specifications.

Tools and Materials Required:

- New Stabilizer Bar (verify correct part number for your vehicle)

- New Stabilizer Bar Bushings (recommended)

- New Stabilizer Bar End Links (recommended)

- Jack and Jack Stands

- Wheel Chocks

- Socket Set (metric or SAE depending on your vehicle)

- Wrench Set (metric or SAE)

- Torque Wrench

- Penetrating Oil (e.g., PB Blaster)

- Hammer (for stubborn bolts)

- Pry Bar

- Safety Glasses

- Gloves

Procedure:

- Safety First: Park the vehicle on a level surface, engage the parking brake, and chock the rear wheels.

- Loosen Lug Nuts: Loosen the lug nuts on the front wheels (or rear wheels if replacing the rear stabilizer bar). Don't remove them completely yet.

- Raise and Secure Vehicle: Use a jack to lift the front of the vehicle and securely support it with jack stands placed under the frame rails. Never work under a vehicle supported only by a jack.

- Remove Wheels: Remove the front wheels.

- Spray Penetrating Oil: Apply penetrating oil to the stabilizer bar end link bolts and bushing bracket bolts. Let it soak for at least 15 minutes. This will make removing the bolts much easier.

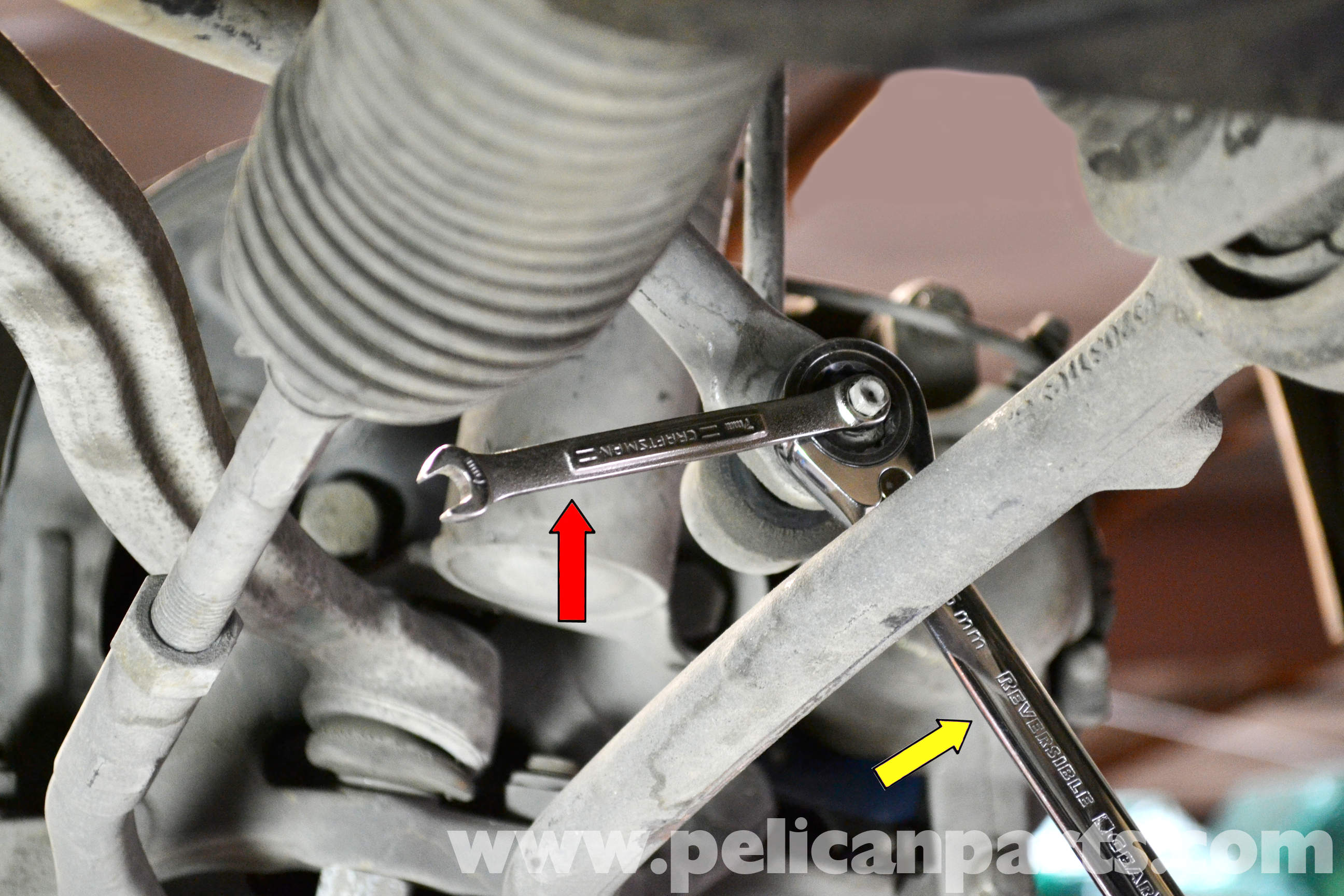

- Remove End Links: Using a socket and wrench, remove the bolts connecting the end links to the stabilizer bar and the suspension arms (or struts). You may need to use a vise grips to hold the ball joint in place while loosening the nut. If the bolts are seized, you may need to use a hammer to tap them loose. Discard the old end links.

- Remove Bushing Brackets: Remove the bolts holding the bushing brackets to the frame or subframe. The brackets hold the stabilizer bar bushings in place. Carefully remove the brackets and set them aside.

- Remove Old Stabilizer Bar: With the end links and bushing brackets removed, the stabilizer bar should now be free to be removed. You may need to maneuver it carefully to clear other suspension components. Note the orientation of the bar for proper installation of the new bar.

- Install New Bushings: Install the new bushings onto the new stabilizer bar. Ensure they are properly positioned and oriented. Lightly grease the inside of the bushings to ease installation.

- Install New Stabilizer Bar: Carefully position the new stabilizer bar in place, making sure it's oriented correctly.

- Install Bushing Brackets: Install the bushing brackets over the bushings and secure them to the frame or subframe with the bolts. Torque the bolts to the manufacturer's specified torque.

- Install New End Links: Install the new end links, connecting the stabilizer bar to the suspension arms (or struts). Torque the bolts to the manufacturer's specified torque.

- Reinstall Wheels: Reinstall the front wheels and tighten the lug nuts by hand.

- Lower Vehicle: Carefully lower the vehicle to the ground and remove the jack stands.

- Torque Lug Nuts: Torque the lug nuts to the manufacturer's specified torque using a torque wrench.

- Test Drive: Take the vehicle for a test drive and listen for any unusual noises. Check the handling and ensure that the body roll is reduced.

Do's and Don'ts / Best Practices

Do's:

- Do use penetrating oil liberally on all bolts before attempting to remove them.

- Do use new bushings and end links when replacing the stabilizer bar. This is a relatively inexpensive way to ensure that the new bar performs optimally.

- Do use a torque wrench to tighten all bolts to the manufacturer's specified torque. Overtightening can damage the bolts or the components they are securing.

- Do consult your vehicle's service manual for specific instructions and torque specifications.

- Do wear safety glasses and gloves to protect your eyes and hands.

Don'ts:

- Don't work under a vehicle supported only by a jack. Always use jack stands.

- Don't use excessive force when removing bolts. If a bolt is seized, try applying more penetrating oil and tapping it with a hammer. If it still won't budge, you may need to use a bolt extractor.

- Don't reuse old bushings or end links. They are likely worn and will not provide optimal performance.

- Don't overtighten bolts. This can damage the bolts or the components they are securing.

- Don't forget to torque the lug nuts after lowering the vehicle.

Conclusion and Recommendations

Replacing a stabilizer bar is a manageable project for a DIYer with some experience. By following these steps and adhering to best practices, you can restore your vehicle's handling and improve its safety. Replacing the bushings and end links along with the bar ensures a complete and long-lasting repair. If you are not comfortable performing this repair yourself, it is always best to consult a qualified mechanic.

Recommendation: If you notice excessive body roll, clunking noises from the suspension, or visible wear and tear on your stabilizer bar components, consider replacing the stabilizer bar and its related hardware. A properly functioning stabilizer bar is essential for safe and predictable handling.