How To Replace A Throwout Bearing

Is your clutch pedal making strange noises? Are you having trouble shifting gears smoothly? You might be dealing with a failing throwout bearing, also known as a clutch release bearing. Replacing it is a necessary repair to prevent more significant, and more expensive, problems down the road. This article will guide you through recognizing the symptoms, understanding the causes, and exploring your repair options.

Identifying a Failing Throwout Bearing

The throwout bearing is a critical component in your vehicle's clutch system, responsible for engaging and disengaging the clutch. When it fails, the symptoms are usually quite noticeable.

Common Symptoms of a Bad Throwout Bearing:

- Noise When Clutch Pedal is Pressed: This is the most common symptom. You'll likely hear a squealing, grinding, chirping, or whirring sound when you depress the clutch pedal. The noise may change in pitch or intensity as you press further down.

- Noise When Clutch Pedal is Released: In some cases, the noise might be present only when the clutch pedal is released. This can indicate that the bearing is worn and not retracting properly.

- Difficulty Shifting Gears: A failing throwout bearing can cause the clutch to not fully disengage, making it difficult to shift gears, particularly into first or reverse. You might experience grinding or clashing sounds as you try to shift.

- Clutch Pedal Vibration: You might feel a vibration in the clutch pedal, especially when the bearing is under load (when the pedal is depressed).

- Clutch Chatter: This feels like a shuddering or shaking sensation when you release the clutch pedal to start moving. While other issues can cause clutch chatter, a failing throwout bearing can contribute.

- Uneven Clutch Engagement: The clutch might not engage smoothly, causing jerky starts or a "grabbing" sensation.

Understanding the Root Cause

The throwout bearing is designed to smoothly transfer force from the clutch fork to the clutch pressure plate. It's a sealed bearing that rides on the transmission input shaft support. The main reasons for throwout bearing failure include:

- Normal Wear and Tear: Over time, the grease inside the bearing can dry out and the bearing surfaces can wear down due to friction and constant use. The bearing experiences immense stress every time you shift gears.

- Lack of Lubrication: Although sealed, the initial lubrication can degrade over time. Some mechanics recommend applying a small amount of high-temperature grease to the input shaft sleeve during installation to ensure smooth operation.

- Contamination: Dirt, debris, and moisture can enter the bearing, even though it's sealed, accelerating wear and causing premature failure.

- Improper Clutch Adjustment: If the clutch cable or linkage is improperly adjusted, the throwout bearing might be constantly under pressure, leading to premature wear.

- Aggressive Driving Habits: Frequent hard shifting, clutch slipping, and "riding the clutch" (resting your foot on the clutch pedal) put excessive stress on the throwout bearing.

- Quality of the Bearing: Using a low-quality replacement throwout bearing can significantly shorten its lifespan.

The Consequences of Ignoring a Failing Throwout Bearing

Ignoring a failing throwout bearing can lead to much bigger problems. Here's what could happen if you delay the repair:

- Complete Clutch Failure: A severely damaged throwout bearing can prevent the clutch from disengaging completely, rendering your vehicle undriveable.

- Damage to the Clutch Pressure Plate: A worn or seized bearing can damage the fingers of the pressure plate, requiring its replacement.

- Damage to the Transmission Input Shaft: The failing bearing can damage the surface where it rides on the transmission input shaft, necessitating costly transmission repairs.

- Increased Repair Costs: The longer you wait, the more components are likely to be damaged, increasing the overall repair bill. Replacing only the throwout bearing initially is significantly cheaper than replacing the clutch, pressure plate, and potentially the transmission.

- Safety Hazard: Difficulty shifting gears can be a safety hazard, especially in situations where you need to react quickly.

Recommended Fixes: Replacing the Throwout Bearing

The only reliable fix for a failing throwout bearing is to replace it. While it's possible to attempt a temporary fix like lubricating the bearing (if accessible), this is unlikely to provide a long-term solution. Because of the labor involved in accessing the throwout bearing, it's almost always recommended to replace the entire clutch kit at the same time. This includes the clutch disc, pressure plate, and pilot bearing (or bushing). This approach saves you money in the long run by avoiding having to pay for the same labor twice should another clutch component fail shortly after the throwout bearing replacement.

Steps Involved in Replacing the Throwout Bearing (and Clutch Kit):

- Vehicle Preparation: Disconnect the battery. Raise the vehicle and securely support it on jack stands.

- Transmission Removal: Disconnect all linkages, wiring, and hydraulic lines connected to the transmission. Support the engine (usually with an engine support bar). Remove the driveshaft or axles, depending on the vehicle's drivetrain. Unbolt the transmission and carefully remove it from the vehicle. This is the most labor intensive step.

- Clutch Assembly Removal: With the transmission removed, you'll have access to the clutch assembly. Mark the orientation of the pressure plate to the flywheel. Loosen the pressure plate bolts gradually in a star pattern to prevent warping. Remove the pressure plate and clutch disc.

- Pilot Bearing/Bushing Removal (if applicable): Remove the pilot bearing or bushing from the end of the crankshaft. Special tools are often required for this step.

- Flywheel Inspection and Machining: Inspect the flywheel for wear, cracks, or heat damage. If necessary, have the flywheel resurfaced by a qualified machine shop. This ensures a smooth, flat surface for the new clutch disc to mate with.

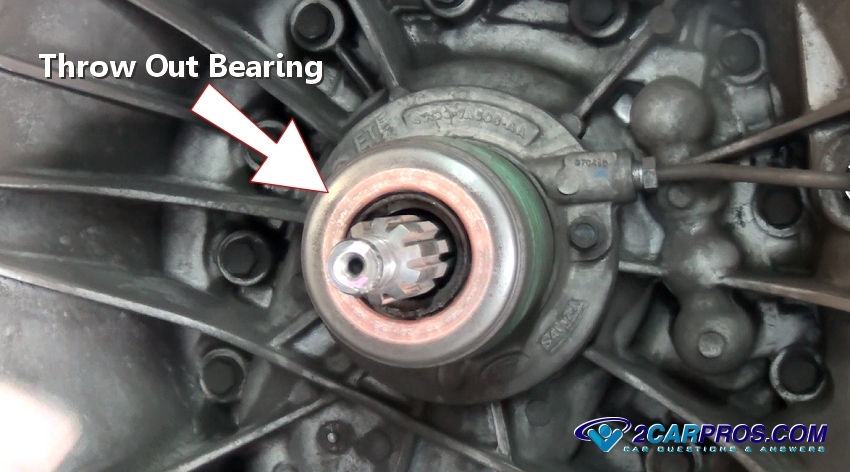

- Throwout Bearing Replacement: Remove the old throwout bearing from the clutch fork. Install the new throwout bearing, ensuring it's properly lubricated and moves freely.

- Component Installation: Install the new pilot bearing/bushing (if applicable). Install the resurfaced (or new) flywheel. Install the new clutch disc and pressure plate, aligning the clutch disc with a clutch alignment tool. Tighten the pressure plate bolts to the manufacturer's specifications in a star pattern.

- Transmission Installation: Carefully reinstall the transmission, aligning it with the engine. Bolt the transmission back into place and reconnect all linkages, wiring, and hydraulic lines.

- Final Steps: Reinstall the driveshaft or axles. Lower the vehicle. Reconnect the battery. Bleed the clutch hydraulic system (if applicable). Adjust the clutch linkage or cable as needed.

- Testing: Start the vehicle and test the clutch engagement and shifting. Check for any unusual noises or vibrations.

Important Considerations:

- This is a complex repair that requires specialized tools and knowledge. If you're not comfortable working on your vehicle's drivetrain, it's best to leave this job to a qualified mechanic.

- Always consult your vehicle's repair manual for specific instructions and torque specifications.

- Use high-quality replacement parts. Saving money on cheap parts can lead to premature failure and more costly repairs in the future.

Cost Estimates and Shop Advice

The cost of replacing a throwout bearing (along with the clutch kit) can vary depending on the vehicle make and model, the quality of the replacement parts, and the labor rates in your area. Generally, you can expect to pay between $800 and $2000 for this repair at a professional shop. The parts themselves (clutch kit) typically cost between $200 and $600, while the remaining cost is labor.

If you're considering having a shop perform the repair, here are some tips:

- Get multiple quotes: Contact several reputable shops in your area and compare their prices.

- Ask about the parts: Find out what brand of clutch kit they use and research its quality.

- Check their reputation: Read online reviews and ask for referrals from friends or family.

- Inquire about warranty: Make sure the shop offers a warranty on their work and the parts they use.

- Ask for a detailed estimate: The estimate should include a breakdown of the parts and labor costs.

Credibility and Supporting Information

While there isn't typically a specific TSB (Technical Service Bulletin) solely for a throwout bearing failure (as it's generally considered a wear item), the symptoms described above are commonly reported by vehicle owners. Online forums and community data often show throwout bearing failures occurring between 80,000 and 150,000 miles, depending on driving habits and the quality of the original bearing. Some manufacturers may have TSBs related to clutch noise or shifting issues that could be indirectly related to a failing throwout bearing. Always consult a reliable repair database or a qualified mechanic for the most up-to-date information specific to your vehicle.

Replacing a failing throwout bearing, ideally with a complete clutch kit, is a crucial repair that can prevent more serious and expensive problems. By recognizing the symptoms early and addressing the issue promptly, you can keep your vehicle running smoothly and safely for years to come.