How To Replace Broken Lug Nut Stud

Encountering a broken lug nut stud can be a frustrating and potentially dangerous situation. Imagine getting a flat tire on the side of the road only to discover you can't properly secure your spare because a lug nut stud is damaged. This article will guide you through identifying the problem, understanding its causes, and ultimately, how to safely resolve it. Addressing a broken lug nut stud is crucial because it directly impacts the safety and integrity of your wheel's attachment to the vehicle. A compromised wheel can lead to vibrations, uneven tire wear, and, in the worst-case scenario, complete wheel detachment, causing a serious accident.

Recognizing the Signs: Symptoms of a Broken Lug Nut Stud

Before diving into the repair process, let's identify the telltale signs of a broken or damaged lug nut stud. Early detection can prevent further complications and ensure a safer driving experience.

Key Symptoms to Watch For:

- Missing Lug Nut: This is the most obvious sign. If you notice a lug nut is missing, especially after having work done on your wheels (tire rotation, brake job, etc.), it's possible the stud broke and the nut came loose.

- Difficulty Tightening Lug Nuts: If you find it unusually difficult to tighten a lug nut, or if it spins freely without ever tightening, the stud might be stripped or broken.

- Cross-Threading: Attempting to force a lug nut onto a cross-threaded stud can damage both the nut and the stud. This can be identified by a grinding or binding sensation while tightening.

- Visible Damage to the Stud: Inspect the studs themselves. Look for signs of bending, cracking, rust, or other damage. Even a small crack can weaken the stud significantly.

- Vibrations: Excessive vibrations, particularly at higher speeds, can indicate a loose or improperly secured wheel, which could be due to a damaged lug nut stud.

- Uneven Tire Wear: While uneven tire wear can be caused by various factors, it's worth investigating if it's accompanied by any of the other symptoms listed here. A loose wheel can contribute to irregular wear patterns.

- Snapping Sound: You might hear a snapping or cracking sound while tightening or loosening lug nuts. This is a strong indication of a stud breaking or being severely damaged.

Understanding the Root Cause: Why Lug Nut Studs Break

Lug nut studs are designed to withstand significant force, but they're not indestructible. Several factors can contribute to their failure. Understanding these causes can help you prevent future problems.

Common Causes of Lug Nut Stud Failure:

- Over-Tightening: This is perhaps the most common cause. Using an impact wrench without setting the torque properly can easily over-tighten lug nuts, stretching and weakening the studs. Always use a torque wrench and adhere to the manufacturer's specified torque settings.

- Cross-Threading: As mentioned earlier, forcing a lug nut onto a stud at an angle can damage the threads, weakening the stud and making it prone to breakage.

- Corrosion: Rust and corrosion can weaken the metal of the stud over time, making it more susceptible to breaking. This is especially common in areas with harsh winters where road salt is used.

- Impact Damage: Hitting a curb or pothole can put significant stress on the wheel and, consequently, the lug nut studs.

- Manufacturing Defects: While rare, manufacturing defects in the studs themselves can also lead to premature failure.

- Improper Installation: If the lug nut studs were not properly installed initially (e.g., not fully seated in the hub), they can be more vulnerable to damage.

- Using the wrong lug nuts: Using lug nuts that aren't designed for your wheels can put undue stress on the studs. Always ensure you're using the correct type and size of lug nuts.

- Wheel spacers: Using wheel spacers without extended studs can put extra stress on the existing studs, making them more prone to failure.

The Consequences of Ignoring a Broken Lug Nut Stud

Driving with a broken lug nut stud is extremely dangerous and should be avoided. The risks are simply too high. Here's what can happen if you ignore the problem:

- Wheel Loosening: With fewer lug nuts properly secured, the wheel is more likely to come loose.

- Vibrations and Instability: A loose wheel will cause noticeable vibrations, making the vehicle unstable and difficult to control, especially at higher speeds.

- Further Damage: A loose wheel can damage other components, such as the brake rotor, wheel hub, and suspension parts, leading to costly repairs.

- Wheel Detachment: The worst-case scenario is complete wheel detachment. This can cause a loss of control and a serious accident, potentially resulting in injury or death.

- Tire Damage: A loose wheel will cause uneven tire wear, and can damage the tire leading to tire failure.

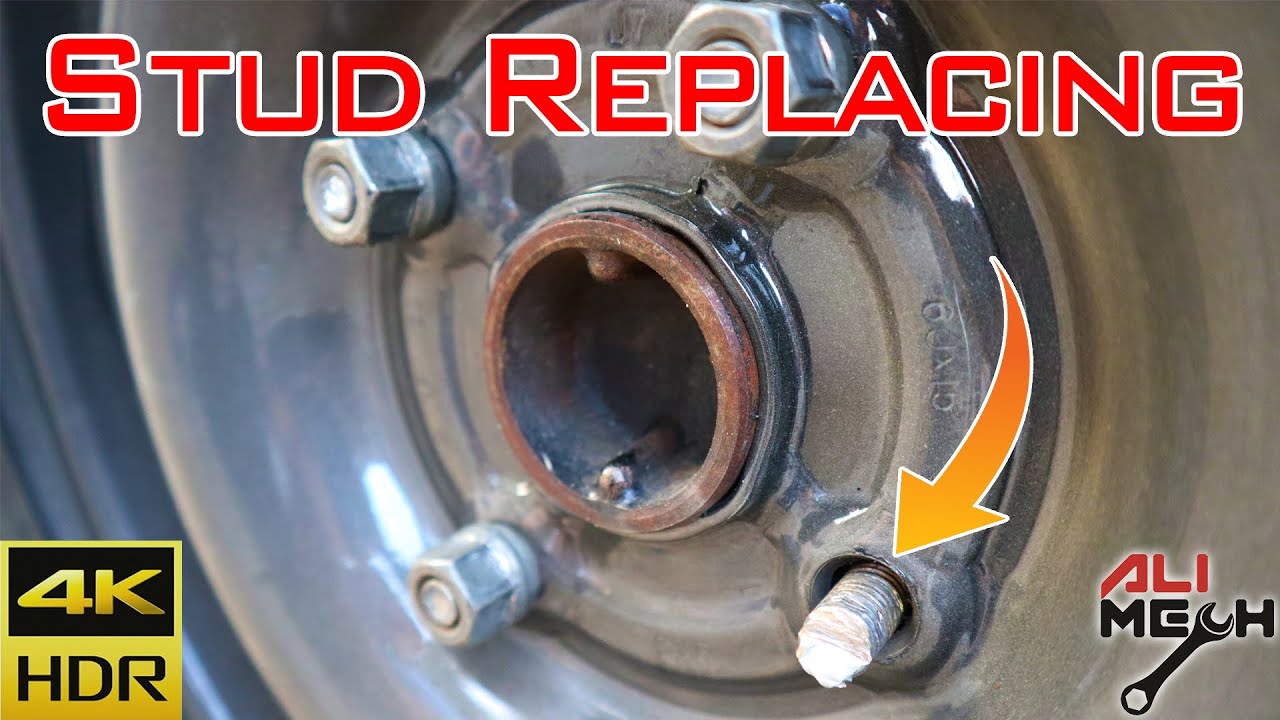

Recommended Fixes: Replacing the Broken Lug Nut Stud

The only safe and reliable solution is to replace the broken lug nut stud. This is a repair best left to a qualified mechanic, especially if you lack experience or the necessary tools. However, if you're comfortable with automotive repairs and have the proper equipment, you can attempt it yourself. Here's a general overview of the process:

Step-by-Step Guide (General Overview):

- Safety First: Park the vehicle on a level surface, engage the parking brake, and use wheel chocks to prevent rolling.

- Loosen Lug Nuts: Loosen the lug nuts on the affected wheel before lifting the vehicle.

- Lift the Vehicle: Use a jack to lift the vehicle and securely support it with jack stands. Never work under a vehicle supported only by a jack.

- Remove the Wheel: Remove the lug nuts completely and take off the wheel.

- Access the Hub: Depending on the vehicle, you may need to remove the brake caliper, rotor, and/or hub assembly to access the back of the hub where the lug nut stud is located. This often requires specialized tools.

- Remove the Broken Stud: In many cases, you can hammer out the old stud from the backside of the hub. Be careful not to damage the hub in the process. If the stud is particularly stubborn, you may need to use a specialized stud removal tool.

- Install the New Stud: Insert the new stud from the backside of the hub.

- Seat the New Stud: There are a few ways to seat the new stud. You can use an impact wrench (carefully, to avoid over-tightening) with a sacrificial lug nut and a stack of washers to pull the stud into place. Alternatively, you can use a ball joint press or a C-clamp.

- Reassemble: Reassemble the brake components, rotor, and/or hub assembly in the reverse order of removal.

- Reinstall the Wheel: Mount the wheel back onto the hub.

- Tighten Lug Nuts: Tighten the lug nuts to the manufacturer's specified torque using a torque wrench. Do not over-tighten.

- Lower the Vehicle: Lower the vehicle back to the ground.

- Double-Check Torque: After driving a short distance (e.g., 50-100 miles), re-torque the lug nuts to ensure they haven't loosened.

Important Considerations:

- Torque Specifications: Always consult your vehicle's owner's manual or a reliable service manual for the correct torque specifications for your lug nuts.

- Replacement Parts: Use high-quality replacement lug nut studs that are specifically designed for your vehicle.

- Professional Assistance: If you're not comfortable with any part of this process, seek professional assistance from a qualified mechanic.

Cost Estimates and Shop Advice

The cost of replacing a broken lug nut stud can vary depending on several factors, including the make and model of your vehicle, the labor rate of the repair shop, and whether any additional components need to be removed or replaced.

Typical Cost Breakdown:

- DIY: If you do the repair yourself, the cost will primarily be for the replacement lug nut stud, which typically ranges from $5 to $20 per stud.

- Professional Repair: A professional repair can range from $50 to $200 per wheel, depending on the complexity of the job and the shop's labor rate. This includes the cost of the stud and labor. If the hub needs to be removed the price will increase accordingly.

Shop Advice:

- Get a Quote: Obtain quotes from several reputable repair shops before committing to the repair.

- Ask About Labor: Inquire about the shop's labor rate and how long they estimate the repair will take.

- Check Reviews: Read online reviews to get an idea of the shop's reputation and quality of work.

- Warranty: Ask about the shop's warranty on parts and labor.

Adding Credibility: TSBs, Community Data, and Common Mileage

While there aren't often specific TSBs (Technical Service Bulletins) issued solely for broken lug nut studs (they are usually related to wheel hubs or bearing assemblies), some manufacturers may address issues related to lug nut torque specifications or wheel fitment that can indirectly impact stud longevity. Consulting a database of TSBs for your specific vehicle make and model can be helpful.

Online automotive forums and communities can also provide valuable insights into common failure points and mileage ranges for lug nut studs. For example, certain vehicle models with specific wheel configurations or higher performance engines may be more prone to stud failures due to increased stress and heat. Searching these forums for discussions related to your vehicle can help you identify potential issues and preventative measures. Always remember that anecdotal evidence from forums is not a substitute for professional diagnosis.

Often, lug nut stud failures are correlated with mileage points where brake services and tire rotations have occurred several times. The repeated removal and installation of the wheels, especially with improper torque procedures, can significantly weaken the studs over time. Keep detailed records of wheel service to keep up with maintenance. It is also prudent to verify that the mechanic is using a torque wrench according to manufacturer specifications.

By understanding the symptoms, causes, and recommended fixes for a broken lug nut stud, you can take proactive steps to ensure your vehicle's safety and prevent potential accidents. Remember that a broken lug nut stud is a serious issue that should be addressed promptly and professionally.