How To Replace Cam Position Sensor

Is your car sputtering, refusing to start, or throwing a mysterious check engine light? Before you resign yourself to an expensive mechanic's bill, consider the humble yet critical Camshaft Position Sensor (CPS). Replacing it can often be a straightforward DIY project, saving you money and providing a deeper understanding of your vehicle's inner workings. Let's dive into how this vital sensor functions, how to diagnose a faulty one, and the step-by-step process of replacing it.

The Case of the Erratic Engine

Imagine you're a conductor leading an orchestra. Each instrument (cylinder) needs to play its part at exactly the right moment to create beautiful music (smooth engine performance). The CPS acts as a key messenger, relaying crucial timing information to the engine control unit (ECU), the orchestra's scorekeeper. When this messenger falters, the music becomes dissonant – resulting in rough idling, misfires, and even a complete refusal to start.

Let's say you're driving down the highway, and suddenly your car starts bucking and losing power. The check engine light illuminates, and you notice a significant drop in fuel economy. Limping to the nearest auto parts store, the diagnostic scan reveals a code related to the camshaft position sensor. This scenario is surprisingly common, and often a straightforward CPS replacement can resolve the issue.

Delving into the Mechanics: How the CPS Works

The CPS's primary function is to monitor the position and speed of the camshaft. The camshaft, driven by the crankshaft via a timing belt or chain, controls the opening and closing of the engine's valves. Precise valve timing is paramount for efficient combustion. The CPS provides the ECU with the necessary information to synchronize fuel injection and ignition timing with the camshaft's rotation.

There are two main types of CPS: Hall-effect sensors and magnetic reluctance (or variable reluctance) sensors. Hall-effect sensors use a magnetic field and a semiconductor to generate a voltage signal that varies based on the position of a rotating trigger wheel or reluctor ring on the camshaft. As the teeth of the reluctor pass the sensor, they interrupt the magnetic field, creating pulses that the ECU interprets as camshaft position. Magnetic reluctance sensors, on the other hand, use a coil of wire wrapped around a permanent magnet. As the reluctor passes, it alters the magnetic field, inducing a voltage in the coil. The frequency and amplitude of this voltage signal correspond to the speed and position of the camshaft.

Regardless of the type, the CPS generates a signal that the ECU uses in conjunction with the crankshaft position sensor (CKP). The CKP monitors the crankshaft's position and speed, providing a reference point for the ECU. By comparing the signals from the CPS and CKP, the ECU can accurately determine the position of each cylinder and control the fuel injectors and ignition coils accordingly.

Pros and Cons of CPS Replacement

Pros:

- Cost-Effective: Replacing the CPS is typically much cheaper than other engine repairs. The sensor itself is relatively inexpensive, and the labor involved is often minimal.

- DIY Friendly: With basic tools and some mechanical aptitude, most amateur mechanics can replace the CPS themselves.

- Improved Engine Performance: A functioning CPS can restore smooth idling, improve fuel economy, and eliminate misfires.

- Prevents Further Damage: Ignoring a faulty CPS can lead to more serious engine problems down the line.

Cons:

- Misdiagnosis: CPS symptoms can sometimes mimic other engine problems, such as a faulty crankshaft position sensor or a vacuum leak. Proper diagnosis is crucial.

- Accessibility: The location of the CPS can vary depending on the vehicle model, and it may be difficult to access in some cases.

- Aftermarket Quality: Not all aftermarket CPS sensors are created equal. Opting for a high-quality replacement sensor from a reputable brand is essential for reliable performance.

Use Cases and Manufacturer Examples

The CPS is used in virtually every modern internal combustion engine. Here are a few examples of how different manufacturers utilize it:

- Toyota: Toyota often positions the CPS on the cylinder head, near the camshaft sprocket. A common issue with older Toyota models is oil leaks contaminating the sensor.

- Ford: Ford frequently uses Hall-effect sensors in their CPS designs. Some Ford engines have both a CPS and a camshaft position actuator (CMPA), which is used for variable valve timing (VVT).

- GM: GM vehicles often locate the CPS near the distributor (if equipped) or on the valve cover.

- BMW: BMW engines often use magnetic reluctance sensors for both the CPS and CKP.

Regardless of the manufacturer, the fundamental principle remains the same: the CPS provides crucial timing information to the ECU.

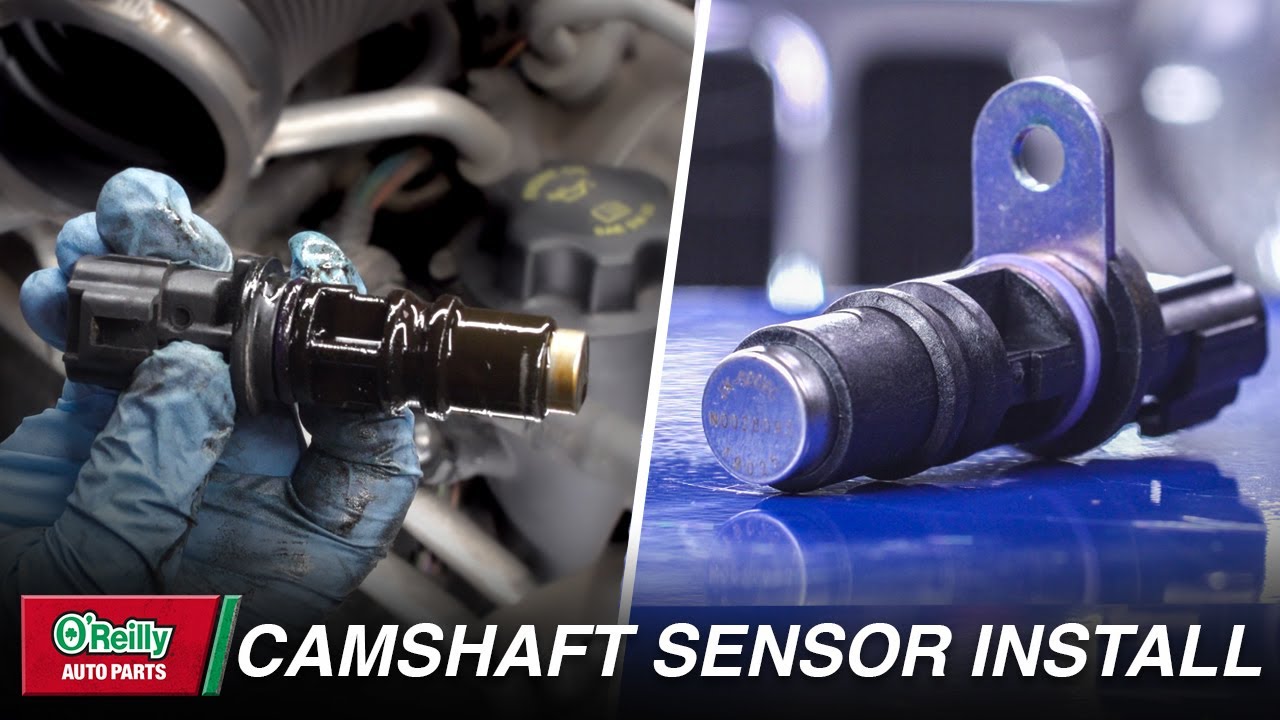

Step-by-Step Guide to Replacing a Cam Position Sensor

Disclaimer: This guide is for informational purposes only. Always consult your vehicle's repair manual for specific instructions and safety precautions. Disconnect the negative battery terminal before beginning any work on your vehicle's electrical system.

- Gather Your Tools: You'll typically need a socket set, wrench set, screwdriver (likely a Phillips head), and possibly a ratchet extension. A multimeter can be helpful for testing the old sensor.

- Locate the CPS: Consult your vehicle's repair manual or search online for the specific location of the CPS on your engine. It's usually located on the cylinder head or valve cover, near the camshaft sprocket.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the CPS. Be mindful of any retaining clips or locks.

- Remove the Old Sensor: Use the appropriate socket or wrench to remove the CPS mounting bolt(s). Gently pull the sensor out of its housing. Note the orientation of the sensor for reinstallation.

- Install the New Sensor: Install the new CPS in the reverse order of removal. Ensure the sensor is properly seated and the mounting bolt(s) are tightened to the specified torque (consult your repair manual).

- Reconnect the Electrical Connector: Reconnect the electrical connector to the CPS, ensuring it is securely latched.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Clear Diagnostic Trouble Codes: Use a scan tool to clear any diagnostic trouble codes (DTCs) related to the CPS.

- Test Drive: Take your car for a test drive to ensure the problem is resolved and the engine is running smoothly.

Troubleshooting Tips

- Sensor Location: Finding the CPS can be tricky. Use online resources like YouTube videos specific to your car model for visual guidance.

- Connector Issues: Corroded or damaged electrical connectors can cause intermittent sensor failures. Clean the connectors with electrical contact cleaner and ensure they are securely connected.

- Wiring Problems: Inspect the wiring harness leading to the CPS for any signs of damage or fraying.

- Incorrect Gap: Some CPS sensors require a specific air gap between the sensor and the reluctor ring. Consult your repair manual for the correct gap specification and use a feeler gauge to verify it.

Real-World Insights and Recommendations

From experience, a common pitfall is opting for the cheapest aftermarket CPS. While tempting, these sensors often have inconsistent performance and a short lifespan. Investing in a sensor from a reputable brand like Bosch, Delphi, or Denso is a worthwhile investment in the long run. Also, when installing the new sensor, applying a small amount of dielectric grease to the electrical connector can help prevent corrosion and ensure a good connection.

Another key point: If the CPS failure is recurring, investigate the possibility of other underlying issues, such as a worn camshaft, damaged reluctor ring, or timing belt/chain problems. These issues can damage the CPS and lead to premature failure.

Finally, if you're unsure about any aspect of the replacement process, don't hesitate to seek professional assistance. A qualified mechanic can accurately diagnose the problem and ensure the CPS is properly installed and functioning correctly.

Replacing a cam position sensor is a manageable task for many car owners, but accurate diagnosis and careful execution are essential. By understanding the sensor's function and following a methodical approach, you can often resolve common engine performance issues and keep your vehicle running smoothly.