How To Replace The Oil Pump

Low oil pressure. Those three words strike fear into the heart of any car enthusiast. It's a warning sign that the lifeblood of your engine – the lubricating oil – isn't reaching vital components, potentially leading to catastrophic (and expensive) damage. While the cause of low oil pressure can be varied, a failing oil pump is a prime suspect. Replacing it is a significant undertaking, but one that's within reach for the mechanically inclined. So, let's dive into the how and why of oil pump replacement.

The Case of the Vanishing Oil Pressure: Why Replace Your Oil Pump?

Imagine your engine as a bustling city. The oil is the delivery network, carrying essential supplies (lubrication, cooling, and cleaning) to keep everything running smoothly. The oil pump is the city's central distribution center, responsible for maintaining constant pressure to ensure these supplies reach every corner – from the main bearings to the valve train. When the pump falters, parts begin to run dry, friction increases, and the city – your engine – grinds to a halt.

Common symptoms of a failing oil pump include a persistent low oil pressure warning light, noisy engine operation (especially rattling from the top end), and, in severe cases, engine knocking. Before you automatically condemn the pump, it's crucial to rule out other potential causes, such as a faulty oil pressure sensor, a clogged oil filter, or excessively worn engine bearings. A mechanical oil pressure gauge should be used to verify the reading from the factory installed sensor.

The Heart of the Matter: How Oil Pumps Work

The oil pump is typically a positive-displacement pump, meaning it delivers a consistent volume of oil with each revolution. There are two main types: gear pumps and rotor pumps. Understanding how they work is key to appreciating their function and potential failure points.

Gear Pumps:

Gear pumps are the most common type. They consist of two meshing gears housed within a close-fitting casing. As the gears rotate, oil is drawn into the spaces between the gear teeth on the intake side of the pump. This oil is then carried around the perimeter of the casing and squeezed out on the outlet side, forcing it into the oil galleries of the engine. The tight clearances between the gears and the casing are critical for maintaining pressure. Wear in these areas can lead to internal leakage and reduced pump output.

Rotor Pumps:

Rotor pumps, also known as gerotor pumps (generated rotor), use an inner rotor with lobes that mesh with an outer rotor, also with lobes. The inner rotor has one fewer lobe than the outer rotor. As the rotors rotate, the volume between the lobes changes, creating suction to draw oil in and pressure to force it out. Rotor pumps are often favored for their compact size and relatively quiet operation. However, they are also susceptible to wear, particularly in high-performance applications.

Regardless of the type, all oil pumps are driven by the engine, either directly off the crankshaft or via an intermediate shaft. This ensures that the pump's output is proportional to engine speed. Most pumps also incorporate a pressure relief valve. This valve opens when the oil pressure exceeds a predetermined limit, preventing damage to the engine and oil system components.

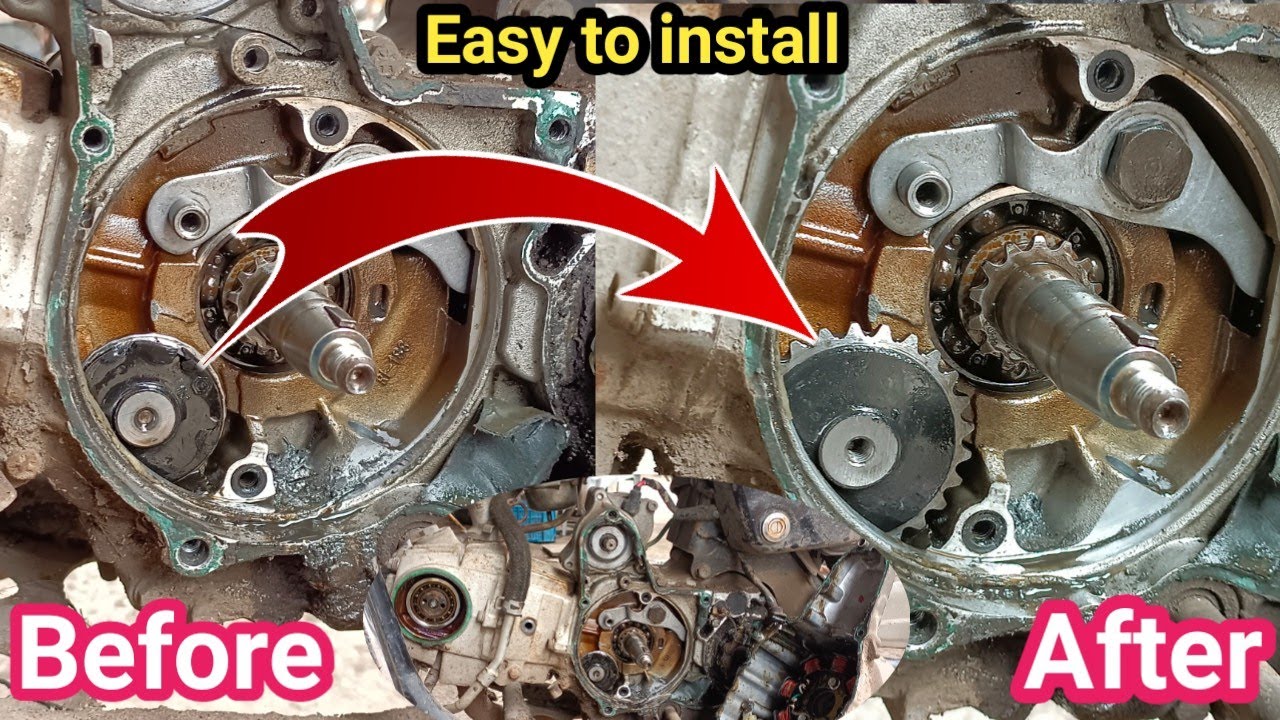

Replacing the Oil Pump: A Step-by-Step Guide

Replacing an oil pump is a moderately complex task that requires careful attention to detail. Here's a general overview of the process. Always consult your vehicle's service manual for specific instructions and torque specifications.

- Preparation: Gather your tools (sockets, wrenches, torque wrench, jack stands, drain pan, etc.) and the new oil pump, gasket, and any necessary seals. Disconnect the negative battery cable.

- Drain the Oil: Remove the oil drain plug and allow the engine oil to drain completely. Dispose of the used oil responsibly.

- Access the Oil Pump: This is where things get vehicle-specific. In most cases, you'll need to remove the oil pan. This may involve disconnecting exhaust components, suspension parts, or other obstructions. Support the engine appropriately.

- Remove the Old Pump: Once the oil pan is removed, you should have access to the oil pump. Disconnect any wiring or hoses attached to the pump. Unbolt the pump from the engine block. Note the position of any shims or spacers.

- Installation: Install the new oil pump, using a new gasket or O-ring. Ensure the pump is properly aligned and torqued to the manufacturer's specifications. Replace any shims or spacers in their original positions.

- Reassembly: Reinstall the oil pan, exhaust components, suspension parts, and any other items you removed to access the oil pump. Use new gaskets or seals where appropriate.

- Refill and Check: Refill the engine with fresh oil to the correct level. Reconnect the negative battery cable. Start the engine and check for leaks. Monitor the oil pressure gauge to ensure the pump is functioning correctly.

Pros, Cons, and Considerations

Pros of DIY Oil Pump Replacement:

- Cost Savings: Labor costs at a professional mechanic can be significant. Doing it yourself saves you money.

- Learning Experience: It's a great way to gain a deeper understanding of your engine and its inner workings.

- Control: You have complete control over the quality of parts used and the care taken during the process.

Cons of DIY Oil Pump Replacement:

- Time Commitment: It can take several hours, or even a full day, to complete the job.

- Complexity: It's not a beginner-level task. You need a good understanding of automotive mechanics.

- Potential for Error: Mistakes can lead to serious engine damage.

- Tools Required: You'll need a decent set of tools, which can be an upfront investment.

Use Cases:

- High-Mileage Vehicles: Oil pumps can wear out over time, especially in vehicles with high mileage.

- Performance Upgrades: Upgrading to a high-volume or high-pressure oil pump can be beneficial for performance engines.

- Known Pump Failures: Some vehicles are known to have issues with their oil pumps. Replacing the pump preemptively can prevent problems.

Manufacturer Examples:

Consider the GM LS engine family, popular in many Chevrolet and GMC vehicles. These engines are generally robust, but the oil pump can be a weak point in high-performance applications. Upgrading to a higher-volume pump from brands like Melling is a common modification. Similarly, some older Subaru EJ engines suffered from oil pump failures, leading many owners to replace the pump as preventative maintenance.

Real-World Insights and Recommendations

Based on practical experience, several key points are worth emphasizing. Firstly, cleanliness is paramount. Ensure that all parts are clean before assembly. Any dirt or debris can damage the new pump. Secondly, prime the oil pump before starting the engine. This involves filling the pump with oil to ensure it's ready to deliver pressure immediately. Some pumps can be primed by hand. Use assembly lube on all moving parts during assembly.

Thirdly, always replace the oil pump pickup tube O-ring. This small O-ring is often overlooked, but it's crucial for preventing air from being drawn into the pump. A leaky O-ring can lead to oil starvation, even with a brand-new pump. Fourth, consider replacing the oil pan gasket at the same time. It's often easier to do it while the oil pan is already removed.

Finally, remember that while a new oil pump can solve the problem of low oil pressure, it's essential to diagnose the root cause. If the low pressure is due to worn engine bearings, replacing the pump will only provide a temporary fix. The underlying issue will still be there, and the new pump will eventually fail as well. A thorough engine inspection is always recommended.

Replacing an oil pump is a challenging but rewarding task. By understanding the principles involved, following the proper procedures, and paying attention to detail, you can successfully restore proper oil pressure to your engine and keep it running smoothly for years to come.