How To Replace Tpms Valve Stem

The dreaded TPMS light. A small, often ignored icon on your dashboard that can escalate from a minor annoyance to a potential safety hazard. While the entire Tire Pressure Monitoring System (TPMS) is a complex interplay of sensors, receivers, and algorithms, often the weakest link, and the most easily serviceable, is the humble valve stem. Over time, these stems can corrode, crack, or simply fail, triggering a TPMS warning. So, how do you replace a TPMS valve stem? Let's dive in.

The Problem: A Leaky Stem

Imagine a bicycle tire. You inflate it, ready for a ride, but notice a slow, persistent leak around the valve. The tire deflates, making the ride uncomfortable and inefficient. A TPMS valve stem failure is a similar, albeit more sophisticated, scenario. The valve stem, which houses the TPMS sensor, is responsible for maintaining the air pressure within your tire. When it fails, it leads to slow leaks, fluctuating tire pressure, and ultimately, a lit TPMS warning light.

The problem is amplified by the fact that TPMS sensors are often integrated directly into the valve stem. This means a simple valve stem replacement isn't always possible; you may need to replace the entire sensor assembly. This increases the cost and complexity of the repair.

Understanding TPMS Mechanics

To appreciate the replacement process, it's crucial to understand how TPMS works. At its core, TPMS is designed to monitor the air pressure in each tire and alert the driver when the pressure falls below a predetermined threshold. There are two main types of TPMS:

- Direct TPMS: This system uses individual pressure sensors mounted inside each tire. These sensors transmit real-time pressure data to the vehicle's central control unit. The sensors are typically attached to the valve stem assembly, making valve stem issues directly linked to sensor functionality.

- Indirect TPMS: This system uses the vehicle's anti-lock braking system (ABS) sensors to monitor tire rotation speed. When a tire loses pressure, its rolling radius decreases, causing it to rotate faster. The ABS sensors detect this difference in rotation speed and trigger the TPMS warning light. Indirect TPMS doesn't use valve stem sensors, so valve stem issues are not related to the TPMS function.

We are primarily concerned with direct TPMS in this article, as that is where valve stem replacement becomes relevant. A direct TPMS sensor, typically battery-powered, continuously monitors tire pressure and temperature. It transmits this data wirelessly to a receiver located within the vehicle. The receiver then relays the information to the vehicle's computer, which displays it on the dashboard and triggers a warning if necessary. The valve stem, therefore, acts as both the inflation point and the physical housing for this critical sensor.

Mechanical Breakdown of the Valve Stem Assembly:

A typical TPMS valve stem assembly consists of several key components:

- Valve Core: The spring-loaded mechanism that allows air to be inflated into the tire and prevents it from escaping.

- Stem Body: The main housing that supports the valve core and connects to the wheel rim.

- Sensor Housing: Encloses the TPMS sensor and provides a mounting point for the stem body.

- Seals and O-rings: Provide airtight seals between the various components and the wheel rim.

- Mounting Hardware: Usually a nut or screw that secures the assembly to the wheel rim.

Failure in any of these components can lead to a leak and trigger the TPMS light. Corrosion, caused by road salt and exposure to the elements, is a common culprit, especially on vehicles driven in harsh climates. Physical damage, such as from hitting a curb, can also crack or break the stem.

Replacing the TPMS Valve Stem: A Step-by-Step Guide (with cautions!)

Warning: TPMS sensor replacement, especially valve stem replacement, can be complex and requires specialized tools. Incorrect installation can damage the sensor or the wheel, leading to costly repairs. If you are not comfortable with automotive repairs, it is best to consult a qualified mechanic.

Tools Needed:

- Jack and Jack Stands

- Lug Wrench

- Tire Changer Machine (or access to one)

- Valve Core Tool

- TPMS Sensor Service Kit (matching your vehicle's TPMS type)

- Torque Wrench

- Soapy Water Solution (for leak testing)

- Programming/Scanning Tool (potentially, depending on the sensor and vehicle)

- Safety First: Park the vehicle on a level surface, engage the parking brake, and chock the wheels. Loosen the lug nuts on the wheel with the faulty valve stem before lifting the vehicle.

- Lift and Secure: Use a jack to lift the vehicle and place it securely on jack stands. Remove the wheel.

- Deflate the Tire: Using a valve core tool, remove the valve core and completely deflate the tire.

- Break the Bead: This is where a tire changer machine is typically required. The machine is used to separate the tire bead (the edge of the tire) from the wheel rim. *Caution: Attempting to do this manually can be dangerous and can damage the tire.*

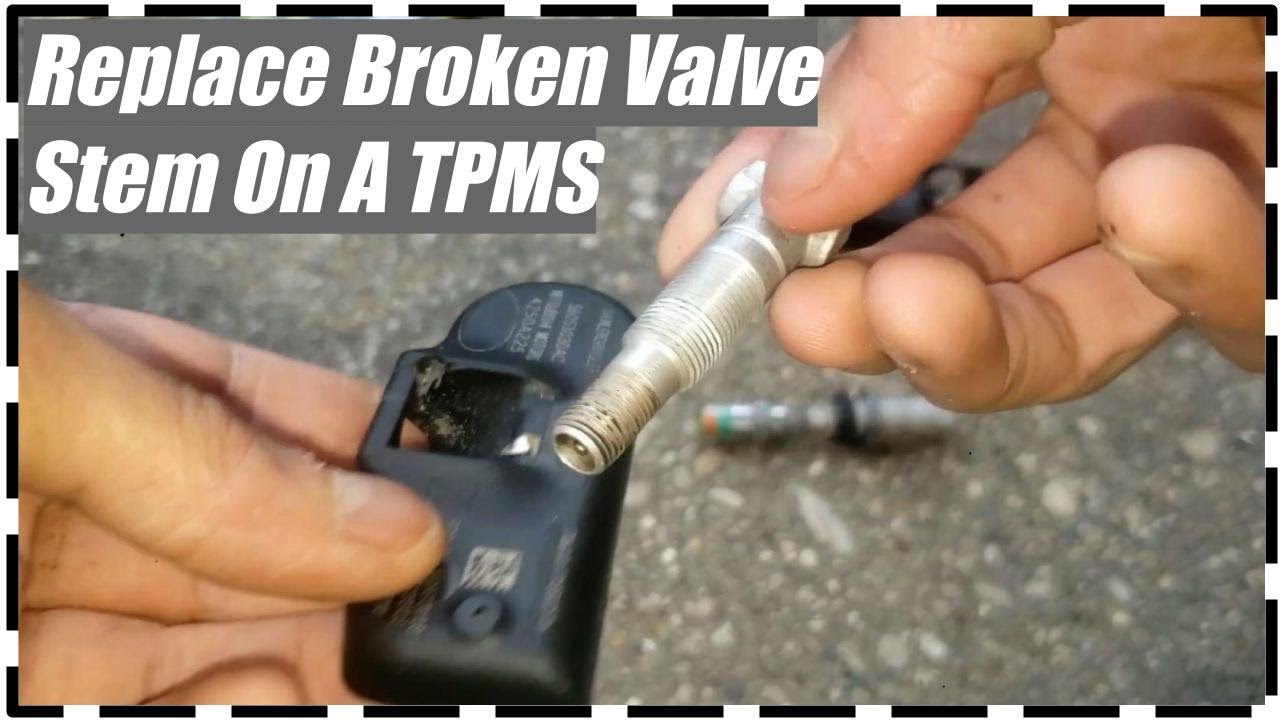

- Remove the Old Sensor/Valve Stem: Once the tire bead is broken, carefully reach inside the tire and remove the old TPMS sensor and valve stem assembly. Note the orientation of the sensor and any specific mounting hardware.

- Install the New Sensor/Valve Stem: Install the new TPMS sensor and valve stem assembly, ensuring it is properly seated and aligned. Use new seals and O-rings from the TPMS sensor service kit. Tighten the mounting hardware to the manufacturer's specified torque. *Caution: Over-tightening can damage the sensor or the wheel rim. Under-tightening can lead to leaks.*

- Re-Mount the Tire: Using the tire changer machine, carefully re-mount the tire onto the wheel rim. Ensure the tire bead is properly seated.

- Inflate the Tire: Inflate the tire to the manufacturer's recommended pressure.

- Leak Test: Apply a soapy water solution around the valve stem and the tire bead. Look for bubbles, which indicate a leak. If a leak is detected, deflate the tire, reseat the bead, and re-inflate.

- Reinstall the Wheel: Reinstall the wheel onto the vehicle and tighten the lug nuts to the manufacturer's specified torque.

- Lower the Vehicle: Lower the vehicle from the jack stands.

- Final Torque: Double-check the lug nut torque after driving a short distance (e.g., 50 miles).

- TPMS Programming/Scanning: Some TPMS sensors require programming or scanning to be recognized by the vehicle's computer. This typically involves using a specialized TPMS programming tool. Consult your vehicle's owner's manual or a qualified mechanic for specific instructions. *Note: Some vehicles can automatically relearn new TPMS sensor IDs after a short drive.*

Pros and Cons of DIY Replacement

Pros:

- Cost Savings: Replacing the TPMS valve stem yourself can save you money on labor costs.

- Learning Opportunity: It provides a hands-on learning experience about your vehicle's systems.

- Control: You have complete control over the parts used and the quality of the work.

Cons:

- Specialized Tools Required: Tire changer machines and TPMS programming tools can be expensive.

- Risk of Damage: Improper installation can damage the sensor, the wheel, or the tire.

- Time-Consuming: The process can be time-consuming, especially for beginners.

- Potential for Error: Programming the new sensor to work with your car can be tricky.

Use Cases and Manufacturer Examples

TPMS valve stem replacement is common in several scenarios:

- Corrosion: Vehicles driven in areas with harsh winters and road salt often experience corrosion of the valve stems.

- Damage: Hitting a curb or other road hazards can damage the valve stem.

- Age: Over time, the rubber seals in the valve stem can dry out and crack, leading to leaks.

- Sensor Failure: If the TPMS sensor itself fails, the entire assembly, including the valve stem, may need to be replaced.

Many aftermarket manufacturers offer TPMS sensor service kits, including replacement valve stems and seals. Examples include Schrader, Dill, and ATE. Some manufacturers, like Ford and GM, offer their own branded TPMS sensor and valve stem assemblies.

Real-World Insights and Recommendations

Based on real-world experience, here are some recommendations to consider:

- Use Quality Parts: Invest in high-quality TPMS sensor service kits from reputable manufacturers. Cheap parts can fail prematurely, leading to further issues.

- Follow Torque Specifications: Always tighten the mounting hardware to the manufacturer's specified torque. Over-tightening is a common cause of damage.

- Consider a Professional: If you are unsure about any step of the process, consult a qualified mechanic. The cost of professional installation may be worth it to avoid potential damage.

- Regular Inspection: Regularly inspect your valve stems for signs of corrosion or damage. Replacing them proactively can prevent future problems.

- Check Compatibility: Ensure that the replacement TPMS sensor is compatible with your vehicle's make, model, and year. Incompatible sensors may not communicate properly with the vehicle's computer.

- Pay attention to the relearn procedure: After installing new sensors, consult your car's owner's manual for specific instructions on how to initiate the TPMS relearn procedure. Some vehicles require a scan tool, while others can automatically relearn the sensor IDs after a short drive.

Replacing a TPMS valve stem can be a straightforward task with the right tools and knowledge. However, it's essential to approach the project with caution and to prioritize safety. Whether you choose to tackle the project yourself or entrust it to a professional, understanding the underlying mechanics of TPMS can help you make informed decisions and ensure the proper functioning of your vehicle's tire pressure monitoring system.