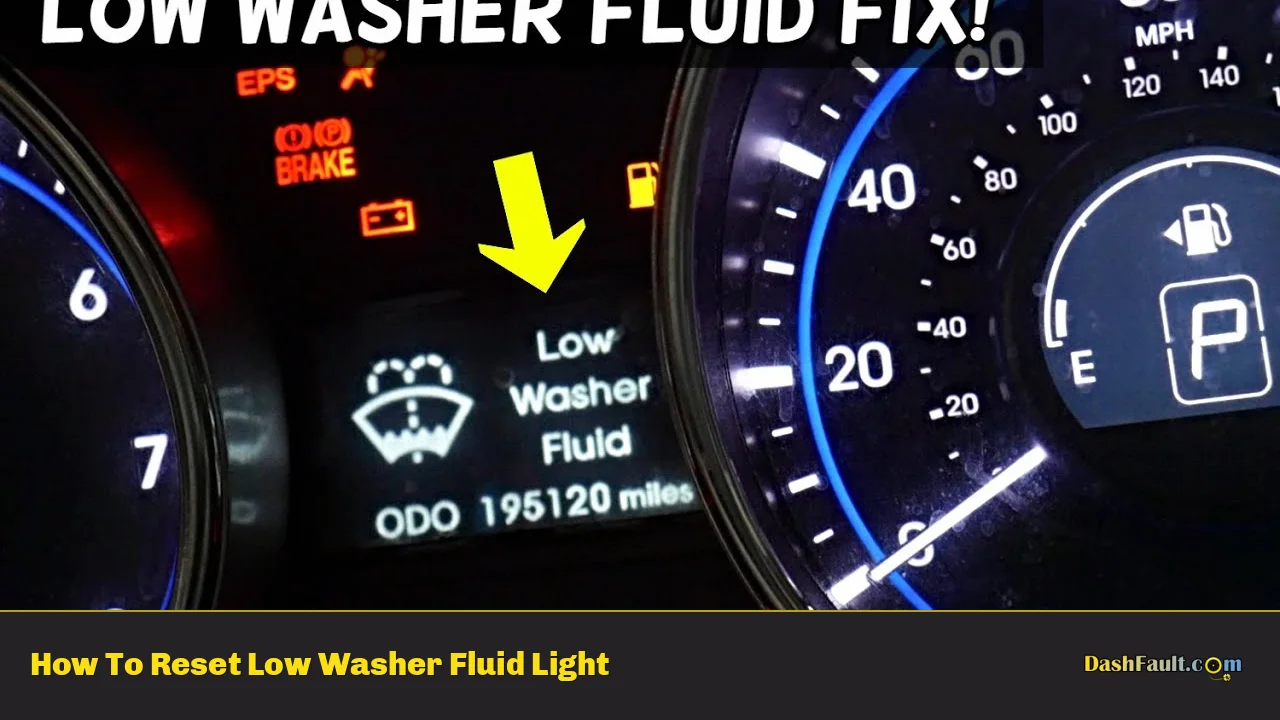

How To Reset Low Washer Fluid Light Infiniti Qx80

The persistent low washer fluid light in your Infiniti QX80 can be a frustrating issue, especially when you've topped off the reservoir. While seemingly minor, a malfunctioning washer fluid sensor can impact your ability to clear the windshield effectively, compromising visibility and safety. This article provides a detailed technical breakdown of how to troubleshoot and potentially reset the low washer fluid light on your QX80, assuming you have a basic understanding of automotive systems and are comfortable performing DIY tasks.

Background: The QX80 Washer System

The Infiniti QX80’s windshield washer system is a relatively straightforward system designed to spray washer fluid onto the windshield to remove dirt, grime, and other debris. It consists of several key components:

- Washer Fluid Reservoir: This is the container that holds the washer fluid. Its capacity varies slightly depending on the model year, but it's generally a large reservoir.

- Washer Pump(s): An electric pump (or pumps, if there's a separate rear window washer) draws fluid from the reservoir and delivers it under pressure to the washer nozzles.

- Washer Nozzles: These are the spray nozzles located on the hood (or cowl) that direct the washer fluid onto the windshield.

- Washer Fluid Level Sensor: This sensor monitors the fluid level in the reservoir and triggers the low washer fluid light on the instrument panel when the level drops below a certain threshold. This is the primary focus of our troubleshooting.

- Wiring and Connectors: Connect the various components to the vehicle's electrical system, enabling pump operation and sensor signal transmission.

- Windshield Washer Switch/Stalk: This controls the activation of the windshield washers.

The system is relatively simple, but problems can arise within each of these components. Often, a fault code is stored in the BCM (Body Control Module) related to the washer system.

Technical Breakdown: How the Washer Fluid Sensor Works

The washer fluid level sensor is typically a float-type sensor. This means it uses a float that rises and falls with the fluid level. The float is connected to a mechanism that changes the resistance of the sensor, and this change in resistance is interpreted by the vehicle's computer as a fluid level reading.

Here’s a more detailed look:

- The Float: The float is a buoyant object designed to float on the surface of the washer fluid. As the fluid level decreases, the float descends.

- The Sensor Mechanism: The float is mechanically linked to a variable resistor or a switch. In the case of a variable resistor (also known as a potentiometer), the position of the float changes the resistance value. In the case of a switch, the float simply opens or closes the circuit at a specific fluid level.

- Signal Transmission: The sensor is connected to the vehicle's electrical system, specifically to the BCM. The BCM monitors the resistance (or the open/closed state of the switch) of the sensor.

- BCM Interpretation: The BCM has a programmed threshold. When the resistance (or switch state) indicates that the fluid level is below the threshold, the BCM activates the low washer fluid light on the instrument panel. It may also set a diagnostic trouble code (DTC) in its memory.

In many modern vehicles like the QX80, the sensor communicates with the BCM using a digital signal rather than a purely analog resistance value. This makes the system more robust to noise and voltage fluctuations.

Common Issues and Maintenance Concerns

Here are some common reasons why your low washer fluid light might stay on, even after refilling the reservoir:

- Faulty Sensor: This is the most common culprit. The sensor itself may be defective, causing it to give an incorrect reading regardless of the fluid level. The float may become waterlogged and sink, or the internal resistance of the sensor may drift out of range.

- Contaminated Fluid: Over time, the washer fluid can become contaminated with dirt, debris, and algae. This contamination can interfere with the sensor's operation, preventing the float from moving freely or affecting the electrical conductivity.

- Wiring Issues: Damaged wiring or corroded connectors can disrupt the signal between the sensor and the BCM. Check for breaks in the wires, loose connections, and corrosion at the sensor connector and at the BCM.

- BCM Malfunction: Although less common, a malfunction in the BCM itself could cause it to misinterpret the sensor signal or to incorrectly activate the low washer fluid light.

- Stuck Float: The float itself may physically stick in the lowered position due to debris or deposits within the reservoir.

- Software Glitch: A rare possibility is a software glitch in the BCM. Sometimes, a software update from the dealer can resolve such issues.

Maintenance Concerns:

- Using the Right Fluid: Always use a high-quality windshield washer fluid that is designed for automotive use. Avoid using plain water, as it can freeze in cold weather and damage the system. Also, some soaps can cause issues with the sensor and the pump.

- Regular Inspection: Periodically inspect the washer fluid reservoir for cracks, leaks, and contamination. Clean the reservoir if necessary.

- Proper Winterization: In cold climates, use a winter-blend washer fluid that is formulated to prevent freezing.

Troubleshooting and Resetting the Light

Here's a step-by-step guide to troubleshooting and potentially resetting the low washer fluid light:

- Visual Inspection: Start by visually inspecting the washer fluid reservoir. Ensure it is filled to the proper level. Check for any signs of leaks or damage to the reservoir or the surrounding area.

- Check the Sensor Connector: Locate the connector for the washer fluid level sensor (it's usually located on the side or bottom of the reservoir). Disconnect the connector and inspect it for corrosion or damage. Clean the connector with electrical contact cleaner and reconnect it securely.

- Test the Sensor (Multimeter): This requires a multimeter. With the connector disconnected, measure the resistance across the sensor terminals. Refer to the QX80's service manual (available online or through a subscription service like Alldata or Mitchell OnDemand) for the correct resistance values for a full and empty reservoir. If the resistance is significantly out of range, the sensor is likely faulty.

- Check Wiring Continuity: Use a multimeter to check the continuity of the wiring between the sensor connector and the BCM. Consult the wiring diagram in the service manual to identify the correct wires. Ensure that there are no breaks or shorts in the wiring.

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to check for any DTCs related to the washer fluid level sensor or the BCM. If there are any codes, research them to determine the underlying cause of the problem. Common codes include B1015 (Washer Fluid Level Sensor Circuit), or codes related to the Body Control Module (BCM).

- Attempt a Reset with a Scanner: Some advanced OBD-II scanners can reset the BCM and clear any stored DTCs. After addressing the potential issue (e.g., replacing the sensor), use the scanner to clear the codes and see if the low washer fluid light goes off.

- Inspect the Float: If accessible (some reservoirs require removal to access the sensor and float), carefully remove the sensor and inspect the float. Ensure that it moves freely and is not waterlogged or obstructed by debris. Clean the float and the inside of the reservoir if necessary.

- Disconnect the Battery (Last Resort): As a last resort, you can try disconnecting the negative battery terminal for 15-20 minutes. This will reset the vehicle's electronic control units, including the BCM. However, be aware that this will also erase other stored data, such as radio presets.

Do’s and Don’ts / Best Practices

Do’s:

- Consult the Service Manual: Always refer to the QX80's service manual for specific instructions and wiring diagrams.

- Use Quality Parts: If you need to replace the sensor or other components, use high-quality OEM or reputable aftermarket parts.

- Disconnect the Battery: Disconnect the negative battery terminal before working on the electrical system to prevent accidental shorts.

- Document Your Work: Take pictures or notes as you disassemble the system to help you reassemble it correctly.

- Cleanliness: Keep the work area and components clean to prevent contamination.

Don’ts:

- Force Anything: If a connector or component is stuck, don't force it. Use penetrating oil or heat to loosen it.

- Ignore Warning Signs: Don't ignore other warning lights or symptoms that may indicate a more serious problem.

- Use Tap Water: Never use tap water in the washer fluid reservoir, as it can contain minerals that can clog the system and damage the sensor.

- Overfill the Reservoir: Overfilling the reservoir can cause leaks and damage to the sensor.

Conclusion

Troubleshooting a persistent low washer fluid light on your Infiniti QX80 requires a systematic approach. By understanding how the washer fluid sensor works, inspecting the components, and testing the wiring, you can often identify and resolve the problem yourself. If you are uncomfortable performing these tasks or if the problem persists, it is best to consult a qualified mechanic. Replacing the sensor is often the solution, but always diagnose the system thoroughly to avoid unnecessary repairs. Using a quality sensor and following the proper installation procedures will ensure that your washer fluid system functions properly and that your windshield remains clear.