How To Schedule An Oil Change

Alright, let's talk about something every car owner needs to know: scheduling and performing an oil change. This isn't just about keeping your car running; it's about protecting your engine, optimizing performance, and saving money in the long run. Think of this article as your comprehensive guide, going beyond the basics and diving into the "why" behind each step.

Purpose: Engine Longevity and Performance

The primary purpose of changing your oil is simple: to lubricate the moving parts within your engine, reducing friction and wear. As oil ages, it breaks down, becomes contaminated with dirt and debris, and loses its ability to effectively protect the engine. Think of it like this: fresh oil is like a clean, efficient workforce, while old oil is like a tired, sluggish team prone to errors. Neglecting oil changes can lead to a host of problems, including reduced engine life, decreased fuel economy, and even catastrophic engine failure. A well-maintained lubrication system is crucial for optimal engine performance and minimizing costly repairs.

Key Specs and Main Parts

Before diving into the process, it's crucial to understand the key components involved. These include:

- Engine Oil: The lifeblood of your engine, responsible for lubrication, cooling, and cleaning. Different engines require different oil viscosities, specified by the manufacturer. Check your owner's manual!

- Oil Filter: This removes contaminants from the oil, preventing them from circulating through the engine. Oil filters have varying filtration efficiencies.

- Drain Plug: Located at the bottom of the oil pan, used to drain the old oil. The drain plug typically has a copper or aluminum crush washer that should be replaced each time.

- Oil Pan: A reservoir that holds the engine oil.

- Dipstick: Used to check the oil level.

- Oil Filler Cap: Where you add new oil.

Crucially, viscosity is a key spec to understand. Oil viscosity is represented by a two-number system (e.g., 5W-30). The first number (with the "W" for Winter) indicates the oil's viscosity at cold temperatures, while the second number indicates its viscosity at operating temperature. Using the wrong viscosity can significantly impact engine performance and longevity.

Scheduling Your Oil Change: Mileage and Time

While manufacturers provide recommended oil change intervals, several factors can influence the ideal schedule. Consider these points:

- Manufacturer's Recommendation: Start with the recommended interval in your owner's manual. This is a baseline.

- Driving Conditions: Severe driving conditions (stop-and-go traffic, towing, off-roading, extreme temperatures) require more frequent oil changes. "Severe" can mean as often as every 3,000 miles.

- Oil Type: Synthetic oils typically offer superior protection and longer intervals compared to conventional oils. A good quality synthetic can often extend intervals to 7,500 or even 10,000 miles, but always monitor your oil's condition.

- Oil Condition Monitoring: While mileage-based intervals are common, consider monitoring your oil's condition. Some vehicles have oil life monitoring systems, which use algorithms to estimate oil degradation. You can also send oil samples to a lab for analysis.

- Time-Based Intervals: Even if you don't drive frequently, oil degrades over time. Generally, change your oil at least every 6 months, regardless of mileage.

How It Works: The Oil Change Process

The oil change process involves several key steps:

- Preparation: Gather all necessary tools and materials, including the correct oil and filter, a wrench for the drain plug, an oil filter wrench, a drain pan, gloves, and a funnel. Make sure you have wheel chocks and jack stands if you are lifting the vehicle.

- Warm Up the Engine: Run the engine for a few minutes to warm the oil, making it flow more easily. CAUTION: Don't overheat the engine!

- Position the Vehicle: Safely lift the vehicle using a jack and secure it with jack stands. Never work under a vehicle supported only by a jack.

- Locate and Remove the Drain Plug: Position the drain pan under the drain plug, then carefully loosen and remove the plug. Allow the old oil to drain completely.

- Remove the Oil Filter: Use an oil filter wrench to loosen and remove the old oil filter. Be prepared for some oil spillage. Lightly lubricate the rubber gasket of the new oil filter with fresh oil.

- Install the New Oil Filter: Screw the new oil filter into place, tightening it according to the manufacturer's instructions (usually hand-tight plus a quarter or half turn).

- Reinstall the Drain Plug: Install a new crush washer on the drain plug and tighten it to the manufacturer's specified torque. Over-tightening can damage the oil pan!

- Add New Oil: Locate the oil filler cap and remove it. Use a funnel to add the correct amount of new oil, as specified in your owner's manual.

- Check the Oil Level: Use the dipstick to check the oil level. Add more oil if necessary, until the level is between the "min" and "max" marks.

- Start the Engine: Start the engine and let it run for a few minutes. Check for any leaks around the drain plug and oil filter.

- Final Check: Turn off the engine and let it sit for a few minutes. Recheck the oil level and add more if needed.

- Dispose of Used Oil Properly: Take the used oil to a designated recycling center.

Real-World Use: Basic Troubleshooting

Even with careful preparation, problems can sometimes arise. Here are a few common issues and how to address them:

- Stripped Drain Plug: If the drain plug threads are stripped, you may need to use a thread repair kit or replace the oil pan.

- Oil Filter Stuck: If the oil filter is difficult to remove, try using a different type of oil filter wrench or piercing the filter with a screwdriver (as a last resort). Be *extremely* careful doing this.

- Oil Leak After Change: Check the drain plug and oil filter to ensure they are properly tightened. If the leak persists, the crush washer may be damaged or the oil filter gasket may be improperly seated.

- Incorrect Oil Level: Adding too much oil can be just as bad as not enough. An overfilled engine can cause foaming of the oil, reducing its lubricating properties. If you overfill, you'll need to drain some oil to bring the level back to normal.

Safety: Handling Hot Components and Used Oil

Safety is paramount when working on your vehicle. Keep these points in mind:

- Hot Engine Components: Be extremely careful when working around the engine, as components like the exhaust manifold can be extremely hot and cause severe burns. Allow the engine to cool down sufficiently before starting the oil change.

- Jacking and Jack Stands: Always use jack stands to support the vehicle after lifting it with a jack. Never rely solely on the jack.

- Used Oil: Used oil contains harmful contaminants and should be handled with care. Wear gloves to avoid skin contact and dispose of it properly. Never pour used oil down the drain or onto the ground!

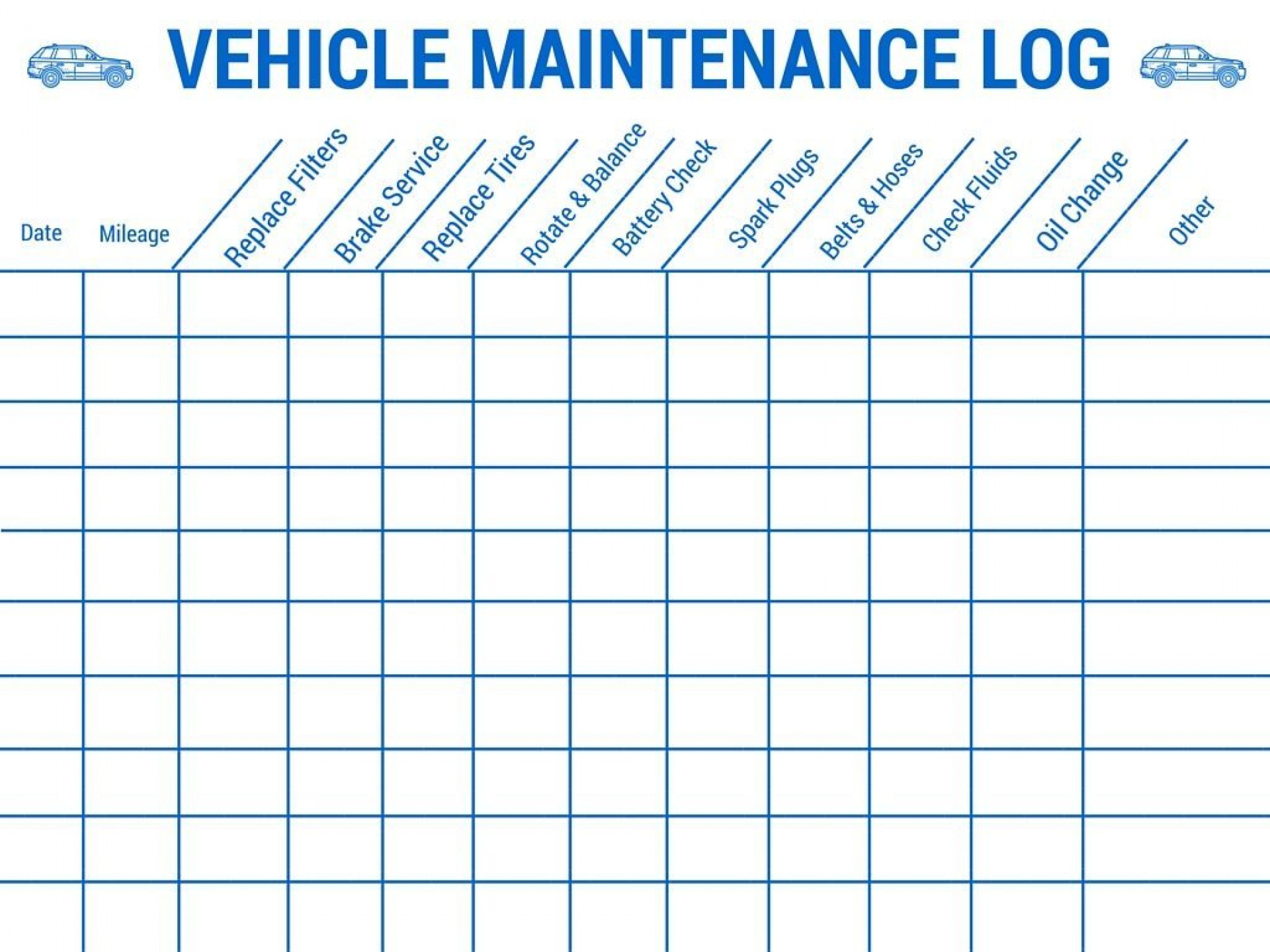

Diagram Access

To help you visualize the oil change process, we have prepared a detailed diagram. This diagram breaks down each step, highlighting critical components and torque specifications. Having a visual aid can be invaluable, especially for those new to DIY oil changes.

We have the file, and you can download the diagram here: [link to hypothetical diagram file].

By understanding the purpose, key components, and safe execution of an oil change, you can confidently maintain your vehicle and extend its lifespan. Remember to consult your vehicle's owner's manual for specific recommendations regarding oil type, filter specifications, and torque values.