How To Shift A Manual Car

Understanding how to properly shift a manual transmission isn't just about avoiding embarrassing stalls at stoplights. It’s about maximizing your car's performance, extending the lifespan of its drivetrain components, and achieving a deeper connection with the driving experience. Whether you're tackling repairs, learning advanced driving techniques, or simply aiming to become a more proficient driver, a solid grasp of the mechanics behind shifting is crucial. This article delves into the inner workings of a manual transmission, offering a detailed explanation for the intermediate car owner, modder, or DIY mechanic.

Purpose of Understanding Manual Transmission

Why bother understanding the intricacies of shifting? The reasons are multifaceted:

- Diagnostics & Repairs: Identifying unusual noises or behaviors in your transmission becomes easier when you understand how each component should function.

- Performance Enhancement: Knowing the optimal shift points for your engine allows you to extract maximum power and acceleration.

- Component Longevity: Smooth, precise shifting minimizes wear and tear on the clutch, synchronizers, and gears, significantly extending their lifespan.

- Driving Enjoyment: Mastering the art of smooth shifting enhances the overall driving experience, making you feel more connected to the car.

- Modifications & Upgrades: If you are planning on modding your car for performance, such as adding a turbo or engine swap, understanding the impact on the transmission and how to upgrade it is critical.

Key Specs and Main Parts of a Manual Transmission

A manual transmission, at its core, is a system of gears designed to multiply the engine's torque to drive the wheels. Let's break down the key components:

- Input Shaft: Connects directly to the engine's crankshaft via the clutch. It spins at the same speed as the engine when the clutch is engaged.

- Clutch: Disconnects the engine from the transmission, allowing you to change gears. Friction material is pressed against the flywheel to engage power, and released when the clutch pedal is pressed.

- Countershaft (or Lay Shaft): A secondary shaft that receives power from the input shaft and drives the gears on the main shaft.

- Main Shaft (or Output Shaft): Delivers power to the driveshaft and ultimately to the wheels. Gears on the main shaft can be selectively engaged to the countershaft.

- Gears: Various sizes of gears on both the countershaft and main shaft provide different gear ratios. Smaller gears provide lower ratios (more torque, less speed), while larger gears offer higher ratios (less torque, more speed).

- Synchronizers (Synchros): Critical components that match the speeds of the gear and the main shaft before engagement. This prevents grinding and allows for smooth shifting. They use friction rings to equalize speeds.

- Shift Forks: Move the synchronizers along the main shaft to engage the desired gear.

- Shift Linkage: The system of rods and levers connecting the gear shift lever in the cabin to the shift forks inside the transmission.

- Transmission Case: Houses all the internal components and provides lubrication.

Key Specs:

- Gear Ratios: Each gear has a specific ratio, representing the relationship between the input and output shaft speeds. For example, a 3:1 gear ratio means the input shaft spins three times for every one rotation of the output shaft.

- Overall Gear Ratio: This takes into account the gear ratio multiplied by the differential ratio. It's the final torque multiplication delivered to the wheels.

- Torque Capacity: The maximum amount of torque the transmission can handle without failing. This is a crucial factor when modifying an engine.

How It Works

The shifting process can be broken down into these fundamental steps:

- Disengaging the Clutch: Pressing the clutch pedal separates the engine from the transmission. This is done by lifting the pressure plate and freeing the friction disc.

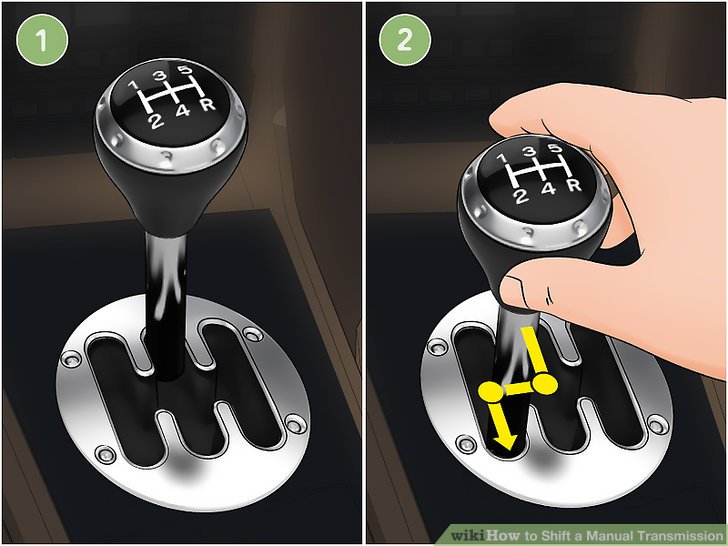

- Selecting a Gear: Moving the gear shift lever engages the appropriate shift fork. The shift fork then moves the corresponding synchronizer towards the gear on the main shaft.

- Synchronization: The synchronizer's friction material engages with the gear, matching its speed to the main shaft speed. This eliminates the speed difference that causes grinding.

- Gear Engagement: Once the speeds are synchronized, the synchronizer slides further to lock the gear to the main shaft.

- Releasing the Clutch: Slowly releasing the clutch pedal gradually re-engages the engine with the transmission, transferring power to the wheels.

Real-World Use - Basic Troubleshooting

Here are some common problems and potential causes, and how understanding the transmission’s workings can help diagnose them:

- Grinding during shifts: This often indicates worn or damaged synchronizers. The synchros aren't able to properly match the speeds of the gear and the main shaft before engagement. Sometimes, it can be caused by a worn clutch that isn't fully disengaging.

- Difficulty shifting into gear: Could be caused by a misadjusted clutch linkage, worn shift bushings, or internal transmission damage. Check for play in the linkage and inspect the bushings for wear.

- Popping out of gear: This could be due to worn gear teeth, bent shift forks, or internal bearing issues. This is a serious problem that requires immediate attention.

- Excessive transmission noise: Whining noises can indicate worn bearings. Grinding or clunking sounds could point to damaged gears. Listen carefully and try to pinpoint the source of the noise.

- Clutch slippage: Engine RPM increases but the car doesn't accelerate proportionally. Indicates a worn clutch disc, glazed flywheel, or issues with the clutch pressure plate.

Pro Tip: Always use the correct type and amount of transmission fluid. Low fluid levels or the wrong type of fluid can lead to premature wear and failure.

Safety - Risky Components

Working on a manual transmission involves several potential hazards:

- Heavy Components: Transmissions are heavy and awkward to handle. Always use proper lifting equipment and support stands to prevent injury.

- Springs & Internal Components: Some internal components, such as springs within the synchronizers, can be under significant pressure. Exercise caution when disassembling these components to avoid injury.

- Sharp Edges: Gear teeth and other internal components can have sharp edges. Wear gloves to protect your hands.

- Used Transmission Fluid: Can contain harmful contaminants. Always wear gloves and eye protection when handling used fluid.

- Clutch Disc Dust: Older clutch discs may contain asbestos fibers, which are harmful if inhaled. Take appropriate precautions when handling old clutch discs.

Important Note: If you're uncomfortable performing any of these repairs or modifications, it's best to consult a qualified mechanic. Improper repairs can lead to further damage and safety hazards.

Diagram: An Essential Tool

Having a detailed diagram of your specific manual transmission is invaluable for repairs, diagnostics, and understanding its operation. The diagram will clearly illustrate the location and relationship of all components, making it easier to identify potential problems and plan your repairs. The diagram is readily available and you can download it to aid in your understanding of the manual transmission.