How To Tell A Spark Plug Is Bad

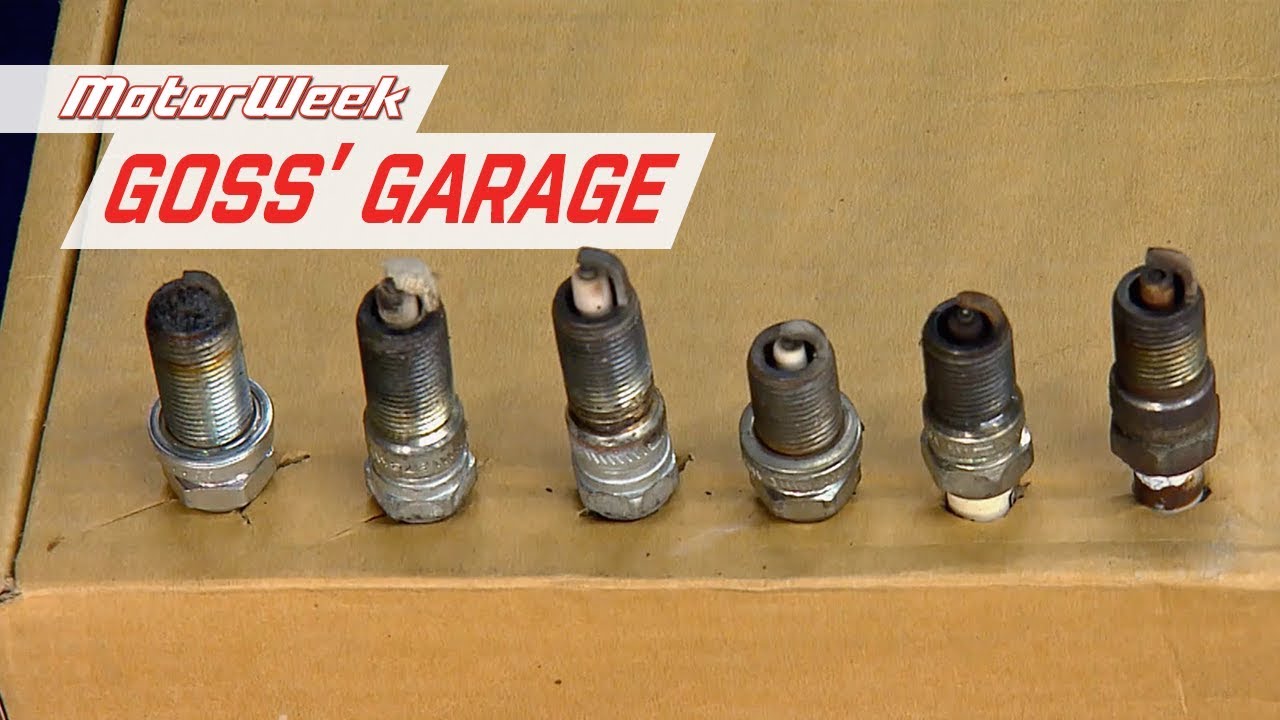

Decoding Spark Plug Diagnostics: A Visual Guide to Engine Health

Diagnosing engine problems can be a daunting task. But before you dive into complex sensor readings or fuel injector issues, a simple visual inspection of your spark plugs can reveal a wealth of information about your engine's health. This article will provide you with a comprehensive guide to understanding what your spark plugs are telling you, enabling you to troubleshoot problems, plan repairs, and even fine-tune your engine's performance. We'll break down the key indicators of a failing or compromised spark plug, equipping you with the knowledge to confidently assess its condition.

Purpose: Why Spark Plug Diagnostics Matter

Understanding spark plug condition is crucial for several reasons:

- Early Problem Detection: Identifying issues like oil leaks, fuel mixture problems, or coolant intrusion early can prevent more significant and costly engine damage.

- Performance Optimization: Spark plugs directly impact engine performance. Diagnosing and replacing worn or fouled plugs can restore lost power, improve fuel economy, and ensure smooth idling.

- Accurate Troubleshooting: Spark plug condition can help narrow down the root cause of engine problems. For example, a specific type of fouling can indicate a problem with a particular cylinder or system.

- Preventative Maintenance: Regularly inspecting spark plugs allows you to identify potential issues before they lead to breakdowns, improving vehicle reliability.

- Learning and Understanding: Examining used spark plugs provides valuable insights into your engine's operating conditions, allowing you to better understand its needs and performance characteristics.

Key Specs and Main Parts

To understand what a spark plug is "saying," it's essential to know its basic components and specifications:

- Terminal: The top of the spark plug that connects to the spark plug wire or coil-on-plug boot.

- Insulator: Usually made of ceramic, the insulator prevents the high-voltage electricity from grounding out before it reaches the spark plug gap.

- Ribs (Corrugations): The ridges on the insulator increase the surface area, preventing voltage from tracking down the outside of the plug.

- Metal Shell: The outer metal body of the spark plug that provides a ground connection to the engine block and houses the internal components.

- Electrode: The center electrode is the conductor that delivers the spark.

- Ground Electrode (Side Electrode): The bent piece of metal attached to the metal shell that provides the other side of the spark gap.

- Spark Plug Gap: The distance between the center electrode and the ground electrode. This gap is critical for proper spark ignition. Incorrect gap can lead to misfires and poor performance.

- Heat Range: A crucial specification indicating the plug's ability to dissipate heat. A "hotter" plug retains more heat, while a "colder" plug dissipates heat more quickly. Selecting the correct heat range is vital for optimal engine performance and preventing pre-ignition or fouling.

- Thread Size and Reach: Spark plugs come in different thread sizes and lengths to fit specific engine cylinder heads. Using the wrong thread size or reach can damage the cylinder head.

Reading the Signs: Common Spark Plug Conditions

Here's a breakdown of what different spark plug conditions can indicate:

- Normal: A tan or light gray color indicates proper fuel mixture, ignition timing, and engine operation. This is the ideal condition.

- Worn: Rounded electrodes and a widened gap indicate normal wear and tear over time. Replace these plugs.

- Oily (Wet or Dry): Oil fouling, caused by oil entering the combustion chamber, is often black and wet. This can be due to worn valve seals, piston rings, or a faulty PCV valve. Addressing the underlying oil leak is essential to prevent further damage.

- Carbon Fouled: A dry, black, sooty deposit indicates a rich fuel mixture, weak spark, or restricted airflow. This can be caused by a faulty oxygen sensor, leaking fuel injector, or vacuum leak.

- Fuel Fouled: Wet and smelling of gasoline, fuel fouling is caused by an over-rich fuel mixture, often due to a stuck-open fuel injector or a faulty choke mechanism (on older vehicles).

- Overheated: A white or glazed insulator indicates excessive engine temperature. This can be caused by lean fuel mixture, incorrect ignition timing, or a cooling system problem. Overheating can lead to pre-ignition and detonation, which can severely damage the engine.

- Detonation/Pre-Ignition Damage: Look for cracked or broken insulators, melted electrodes, or pitting on the ground electrode. This is a sign of severe engine distress caused by uncontrolled combustion. This often requires immediate attention and can be a sign of improper timing.

- Bridged Gap: Carbon or other deposits bridging the gap between the electrodes can prevent the spark from jumping.

- Physical Damage: Cracked or broken insulators indicate physical damage, often from improper installation or detonation.

Real-World Use: Basic Troubleshooting Tips

Here are some practical troubleshooting tips based on spark plug conditions:

- Inspect All Plugs: Don't just check one plug. Examining all the plugs can reveal consistent patterns or cylinder-specific issues.

- Compare to Reference Charts: Use online resources or automotive repair manuals that provide visual examples of different spark plug conditions for comparison.

- Check the Gap: Use a spark plug gapping tool to verify the gap is within the manufacturer's specifications. Adjust if necessary (for new plugs only).

- Consider the Engine's History: Has the engine been modified? Has it experienced any recent problems? This information can help you interpret the spark plug condition.

- Address the Root Cause: Don't just replace the spark plugs without addressing the underlying cause of the problem. For example, replacing oily plugs without fixing the oil leak will only result in the new plugs fouling again.

- Use a Compression Tester: If you suspect a cylinder-specific problem (e.g., one oily plug), a compression test can help diagnose issues like worn piston rings or valves.

- Consider a Leak-Down Test: A leak-down test can further pinpoint the source of compression loss, indicating whether the issue is with the valves, piston rings, or head gasket.

- Consult a Mechanic: If you're unsure about the diagnosis or repair, consult a qualified mechanic.

Safety: Handling Spark Plugs

While working with spark plugs is generally safe, it's essential to take precautions:

- Disconnect the Battery: Before working on the ignition system, disconnect the negative battery terminal to prevent accidental shocks.

- Wait for the Engine to Cool: Never handle spark plugs on a hot engine. Allow the engine to cool completely before removing or installing plugs.

- Use Proper Tools: Use a spark plug socket with a rubber insert to protect the spark plug insulator.

- Torque Properly: Tighten spark plugs to the manufacturer's specified torque. Over-tightening can damage the cylinder head, while under-tightening can cause leaks.

- Handle with Care: Spark plug insulators are fragile. Avoid dropping or banging them, as this can cause cracks.

- Dispose of Properly: Used spark plugs can contain contaminants. Dispose of them properly according to local regulations.

By carefully examining your spark plugs, you can gain valuable insights into your engine's health and performance. This knowledge empowers you to diagnose problems accurately, perform preventative maintenance, and ensure your engine runs smoothly for years to come. Remember to prioritize safety and consult a professional mechanic when needed.

We have a detailed spark plug diagnostic chart available for download. This chart provides visual examples and detailed descriptions of various spark plug conditions to aid in your diagnosis.