How To Tell Which Engine I Have

So, you’re ready to dive a little deeper under the hood, huh? Knowing exactly what engine you're working with is absolutely critical for everything from basic maintenance to serious modifications. Whether you're ordering parts, researching repair procedures, or planning a sweet engine swap, being 100% certain about your engine's identity will save you time, money, and a whole lot of frustration. Think of it as the DNA of your car's powerplant.

Why Engine Identification Matters

Why is knowing your engine so important? Well, imagine trying to replace a worn-out serpentine belt without knowing the engine type. You might order the wrong belt, leading to a frustrating return trip and a delay in getting your car back on the road. Or, consider planning a performance upgrade. The wrong parts designed for a different engine could damage your engine or completely fail to provide the desired performance boost. Accurate engine identification is paramount for:

- Ordering the correct parts: The automotive aftermarket is vast, and parts are often engine-specific.

- Accessing accurate repair information: Service manuals, online forums, and repair databases are organized by engine type.

- Planning modifications: Engine-specific upgrades require knowing the precise engine model.

- Understanding your vehicle's specifications: Horsepower, torque, fuel economy, and other specs are tied to the engine.

- Diagnosing problems effectively: Many diagnostic procedures rely on engine-specific information.

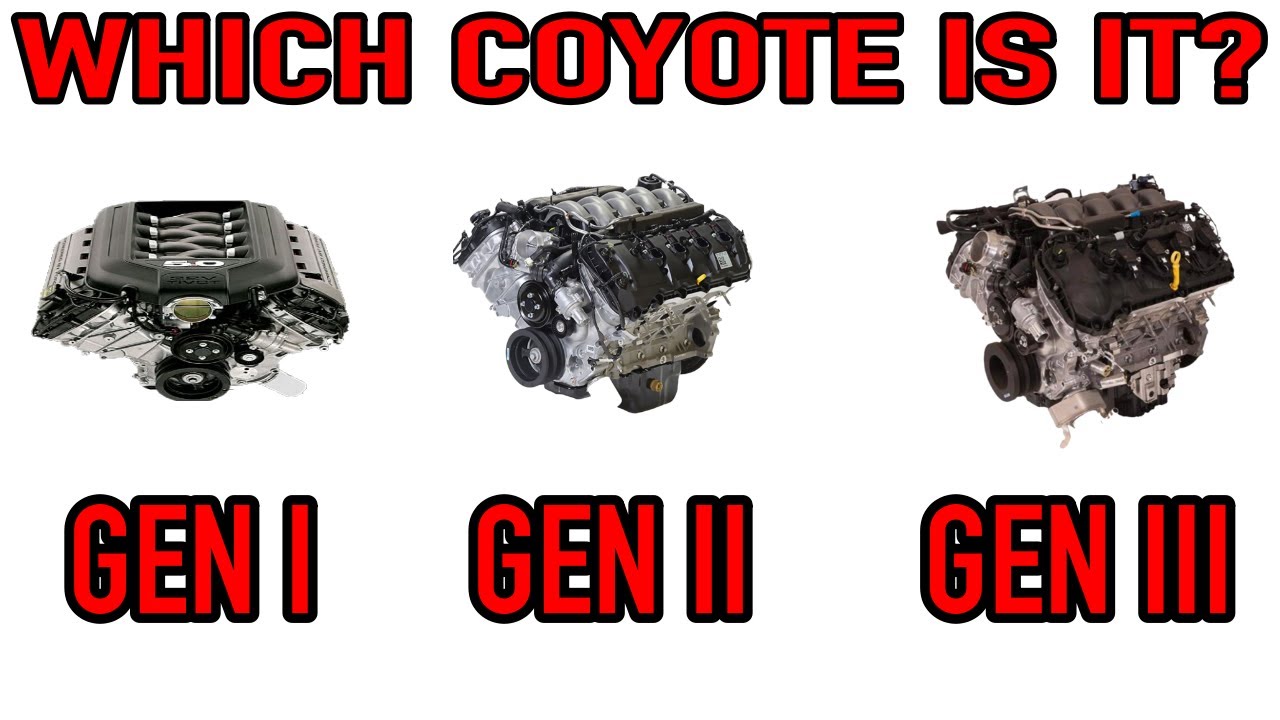

Key Specs and Main Parts to Consider

Identifying your engine involves looking at several key specifications and components. These features, when combined, provide a unique "fingerprint" for your engine. Here are the critical areas to examine:

Engine Block Markings

The engine block itself usually has stamped markings. These are your first clue. Look for alphanumeric codes stamped directly into the metal. These might be located on the side of the block, near the bellhousing (where the engine connects to the transmission), or on the front of the block near the water pump. You'll likely need to clean the area thoroughly with a wire brush or degreaser to reveal the markings. Document everything you find – every letter and number is important! Consult with online engine code databases or your vehicle's service manual to decipher these codes. These codes typically indicate:

- Engine Family: Broad category of engines sharing a similar design.

- Displacement: The total volume displaced by all the pistons in the engine, usually measured in liters (L) or cubic inches (CID).

- Production Date: When the engine was manufactured.

- Specific Variant: A more precise identification within the engine family, denoting specific features or tuning.

Cylinder Head Markings

Similar to the engine block, the cylinder head (the part that sits on top of the block and houses the valves and camshaft(s)) often has cast or stamped markings. These markings can indicate the cylinder head design, valve size, and other crucial details. The markings can be cast into the head itself (raised lettering) or stamped onto a machined surface. Again, cleanliness is key. Knowing the head casting number is important because different heads drastically affect engine performance and compatibility with other components.

Engine Configuration

The overall arrangement of the engine's cylinders also is important. Common configurations include:

- Inline Engines: Cylinders are arranged in a single straight line. (e.g., Inline-4, Inline-6)

- V-Engines: Cylinders are arranged in two banks forming a "V" shape. (e.g., V6, V8)

- Flat Engines (Boxer Engines): Cylinders are arranged horizontally on either side of the crankshaft. (e.g., Subaru's Boxer engines)

Knowing the configuration narrows down the possibilities significantly.

Valve Train Configuration

The valve train controls the opening and closing of the engine's intake and exhaust valves. Common configurations include:

- OHV (Overhead Valve): Valves are operated by pushrods and rocker arms, with the camshaft located in the engine block.

- OHC (Overhead Cam): Camshaft is located in the cylinder head, directly or indirectly operating the valves.

- SOHC (Single Overhead Cam): One camshaft per cylinder head.

- DOHC (Dual Overhead Cam): Two camshafts per cylinder head, one for intake valves and one for exhaust valves.

The location and number of camshafts will be evident by examining the cylinder head. Also, count the number of valves per cylinder – this is typically 2, 3, 4, or even 5. DOHC engines often have 4 valves per cylinder, while older OHV engines often have 2.

Fuel Delivery System

The way the engine receives its fuel is a major distinguishing factor. Look for:

- Carburetor: A device that mixes air and fuel mechanically. Older vehicles commonly used carburetors.

- Fuel Injection: An electronic system that injects fuel directly into the intake manifold or cylinder. Fuel injection systems are further divided into:

- Throttle Body Injection (TBI): Fuel is injected into the throttle body, similar to a carburetor.

- Multi-Port Fuel Injection (MPFI): Fuel is injected into each individual intake port, near the intake valve.

- Direct Injection: Fuel is injected directly into the combustion chamber.

The presence of fuel injectors, a fuel rail, and an electronic control unit (ECU) points to a fuel-injected engine.

Real-World Use – Basic Troubleshooting Tips

Once you’ve identified your engine, you can use that knowledge to troubleshoot common problems. Here are a few examples:

- Misfires: If you know you have a DOHC engine with coil-on-plug ignition, you can focus your attention on the individual ignition coils and spark plugs.

- Rough Idle: Knowing your engine's fuel injection type can help you diagnose vacuum leaks or fuel injector problems.

- Overheating: Identifying the engine's cooling system components (water pump, thermostat housing, radiator) allows you to inspect them for leaks or malfunctions.

Safety Considerations

Working on engines involves inherent risks. Here are some safety precautions to keep in mind:

- Disconnect the battery: Always disconnect the negative battery cable before working on any electrical components.

- Work in a well-ventilated area: Exhaust fumes and cleaning solvents can be hazardous.

- Wear safety glasses: Protect your eyes from flying debris.

- Be careful with hot surfaces: Allow the engine to cool down completely before touching any hot components.

- Use proper lifting equipment: Engines are heavy! Use an engine hoist and appropriate lifting chains to avoid injury.

- Fuel System Precautions: Fuel is highly flammable. Ensure no sparks or open flames are nearby when working on the fuel system.

Identifying your engine is a fundamental skill for any serious DIY mechanic. By carefully examining the engine block, cylinder head, and other key components, you can unlock a wealth of information and ensure you're working on the correct engine. It takes time and patience, but it’s a crucial step towards understanding and maintaining your vehicle.