How To Tell You Need New Brakes

Knowing when your brakes need replacing is crucial for your safety and the longevity of your vehicle. This isn't just about reacting to obvious problems; it's about understanding the subtle signs that indicate wear and tear before they escalate into dangerous situations. This article will equip you with the knowledge to assess your brake system like a seasoned DIYer, enabling you to make informed decisions about maintenance and repairs.

Why This Knowledge Matters

Understanding the intricacies of your brake system goes beyond simply knowing when to schedule a mechanic's appointment. With this knowledge, you can:

- Perform proactive maintenance: Catch minor issues before they become major, expensive repairs.

- Accurately diagnose problems: Avoid being misled by generic "brake job" quotes and understand exactly what needs replacing.

- Make informed decisions about parts: Choose the right brake pads, rotors, and other components for your vehicle and driving style.

- Potentially save money: By performing some brake maintenance tasks yourself, you can reduce labor costs.

- Enhance your driving safety: A properly functioning brake system is the most important safety system on your vehicle.

Key Specs and Main Parts of Your Brake System

Your brake system is a complex assembly of interconnected components working in harmony. Here's a breakdown of the key players:

- Brake Pads: These friction materials press against the rotors to slow down your wheels. They are typically made of organic, semi-metallic, or ceramic compounds. Worn brake pads are the most common cause of brake issues.

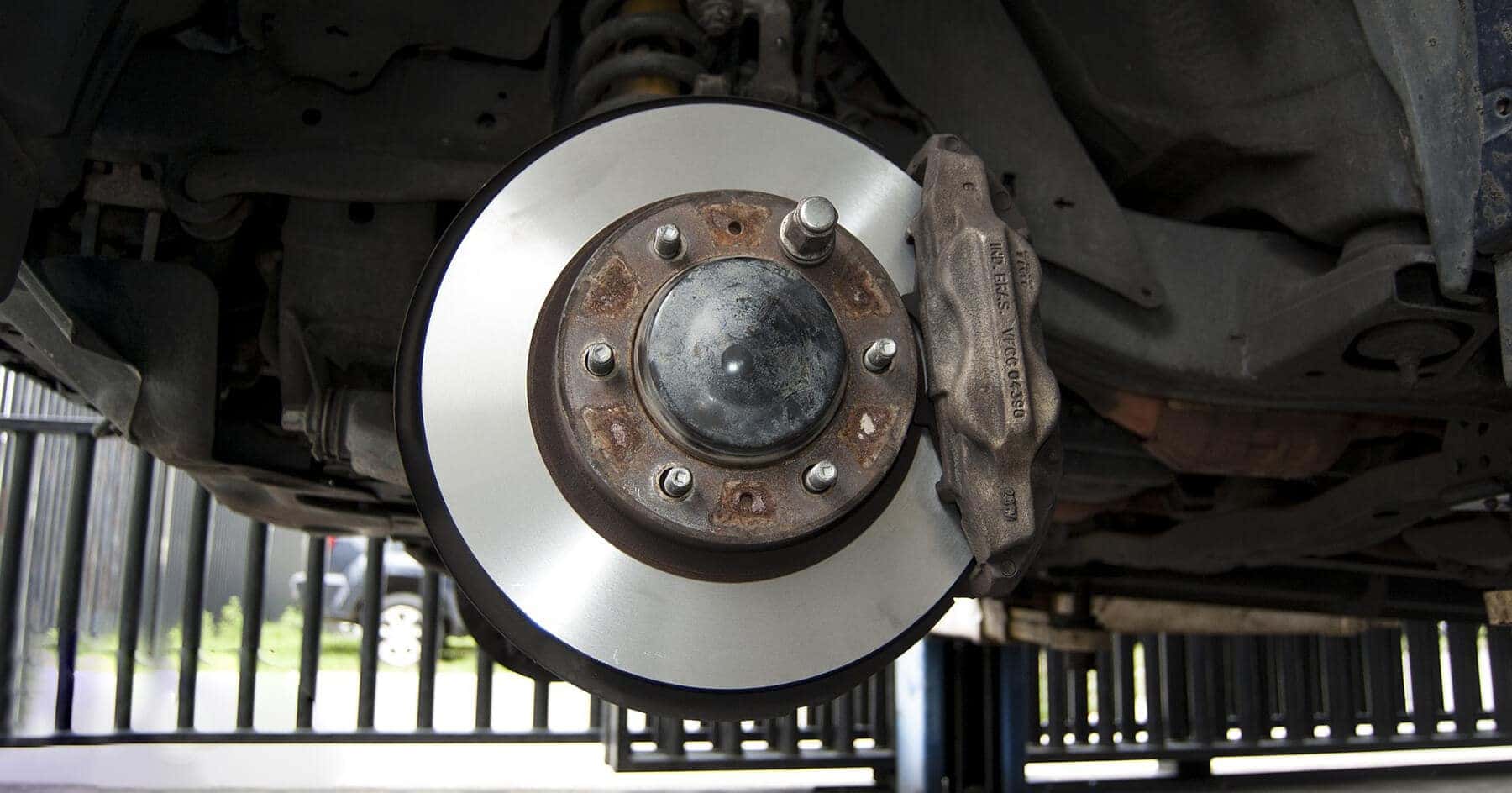

- Rotors (or Discs): These metal discs rotate with your wheels. The brake pads clamp onto them to generate friction and stop the vehicle. Rotors can warp, crack, or wear thin over time.

- Calipers: These hydraulic clamps house the brake pads and contain pistons that press the pads against the rotors. Calipers can seize up or leak brake fluid.

- Brake Lines: These hoses and hard lines carry brake fluid from the master cylinder to the calipers. Brake lines can corrode, crack, or leak.

- Master Cylinder: This hydraulic pump generates pressure when you press the brake pedal, sending brake fluid to the calipers. A failing master cylinder can cause a soft or spongy brake pedal.

- Brake Booster: This vacuum-assisted device amplifies the force you apply to the brake pedal, making it easier to stop. A faulty brake booster can result in a hard brake pedal.

- Anti-lock Braking System (ABS): This system prevents the wheels from locking up during hard braking, allowing you to maintain steering control. The ABS system includes sensors, a control module, and valves.

- Parking Brake (or Emergency Brake): This mechanical system provides a secondary braking force, typically used to hold the vehicle in place when parked. Parking brakes often use cables and levers.

Understanding Brake System Symbols

While we don't have a visual diagram here, understanding common symbols is still essential. Here's a breakdown of what you might encounter in a schematic or repair manual:

- Lines: Solid lines typically represent hydraulic lines or mechanical linkages. Dashed lines may indicate vacuum lines or electrical connections.

- Colors: Colors often differentiate between different types of fluids (e.g., brake fluid vs. coolant) or signal different circuits. Check the diagram's legend.

- Icons: Standard icons represent specific components like the master cylinder, calipers, rotors, and sensors. Look for a legend to identify unfamiliar icons.

How Your Brake System Works

The process is quite simple:

- When you press the brake pedal, you push a piston inside the master cylinder.

- This piston pressurizes the brake fluid, which travels through the brake lines to the calipers.

- Inside the calipers, the brake fluid pushes on the caliper pistons.

- These pistons then force the brake pads against the rotors.

- The friction between the pads and rotors slows down the wheels, stopping the vehicle.

Real-World Use: Troubleshooting Brake Problems

Here's how to apply this knowledge to diagnose common brake issues:

Squealing or Screeching Noises

This is often the first sign of worn brake pads. Some brake pads have wear indicators – small metal tabs that rub against the rotor when the pads are thin, creating a squealing noise. Check the thickness of your brake pads. If they are less than 3mm (about 1/8 inch) thick, they need replacing.

Grinding Noises

This indicates that the brake pads are completely worn down, and the metal backing plate is rubbing directly against the rotor. This is a serious problem that can damage the rotors and compromise your braking ability. Stop driving the vehicle immediately and have the brakes inspected.

Pulsating Brake Pedal

This is often caused by warped rotors. As the rotor rotates, the warped surface causes the brake pads to grip unevenly, resulting in a pulsating sensation in the pedal. Rotors can sometimes be resurfaced (turned), but if they are too thin, they will need to be replaced.

Spongy or Soft Brake Pedal

This can be caused by air in the brake lines or a failing master cylinder. Bleeding the brakes (removing air from the lines) may resolve the issue. If the problem persists, the master cylinder may need to be replaced.

Longer Stopping Distances

This is a general symptom that can be caused by a variety of factors, including worn brake pads, glazed rotors, or low brake fluid. Inspect all brake components and address any identified issues.

ABS Light On

This indicates a problem with the anti-lock braking system. The ABS system includes various sensors that monitor wheel speed. A faulty sensor, wiring issue, or problem with the ABS control module can trigger the light. You'll likely need an OBD-II scanner to diagnose the specific problem.

Pulling to One Side During Braking

This can be caused by a stuck caliper, uneven brake pad wear, or a problem with the brake lines. If one caliper is not functioning properly, it can cause the vehicle to pull to that side during braking.

Safety: Brake System Components to Handle with Care

Working on brakes involves handling potentially hazardous components:

- Brake Fluid: Brake fluid is corrosive and can damage paint and other surfaces. Wear gloves and eye protection when handling brake fluid. Dispose of used brake fluid properly. Never reuse brake fluid.

- Brake Dust: Brake dust can contain asbestos (in older vehicles) or other harmful materials. Avoid breathing in brake dust. Wear a dust mask and clean brake components with a brake cleaner that is specifically designed to minimize dust.

- Springs and Retaining Clips: Caliper springs and retaining clips can be under tension. Use caution when removing and installing these components to avoid injury.

- Hydraulic Pressure: Brake lines are under significant pressure. Never disconnect a brake line without first relieving the pressure.

Final Thoughts

Understanding your brake system is paramount for both safety and cost-effectiveness. While some repairs are best left to professionals, armed with this knowledge, you can proactively maintain your brakes, diagnose problems accurately, and make informed decisions. Always prioritize safety and consult a qualified mechanic if you are unsure about any aspect of brake repair.