How To Test A 1 Wire Oil Pressure Sensor

Testing a 1-wire oil pressure sensor is a relatively straightforward process that can save you time, money, and potential engine damage. This guide will walk you through the steps, providing clear instructions and helpful context to ensure you get accurate results.

Why Testing Your Oil Pressure Sensor Matters

Your engine's oil pressure is critical to its longevity and performance. The oil pump circulates oil throughout the engine, lubricating moving parts and preventing excessive wear. The oil pressure sensor, also known as an oil pressure sender, is responsible for monitoring this vital pressure and relaying that information to your vehicle's dashboard gauge or warning light. If the sensor malfunctions, it can provide inaccurate readings, leading to serious problems. These issues can range from falsely indicating low oil pressure (causing unnecessary worry and potential repair attempts) to, more dangerously, failing to alert you to an actual drop in oil pressure, which can result in catastrophic engine failure.

A faulty sensor can lead to the following:

- Incorrect Gauge Readings: The gauge may display erratic, unusually high, or unusually low readings, even when the actual oil pressure is within the normal range.

- False Warning Lights: The oil pressure warning light may illuminate unnecessarily, causing anxiety and potential misdiagnosis.

- Failure to Detect Low Oil Pressure: The most dangerous scenario is when the sensor fails to detect a genuine drop in oil pressure. This can happen due to a failing oil pump, a leak in the oil system, or a clogged oil filter. Without a proper warning, your engine could suffer severe damage.

- Engine Damage: Continued operation with low oil pressure can lead to bearing failure, piston damage, and even complete engine seizure.

Therefore, regularly testing your oil pressure sensor is a proactive measure to ensure your engine's health and avoid costly repairs.

How to Test a 1-Wire Oil Pressure Sensor

A 1-wire oil pressure sensor is relatively simple in its design and function. It essentially acts as a variable resistor, changing its resistance based on the oil pressure it senses. This resistance is then read by the vehicle's gauge or computer. Here's a step-by-step guide to testing one:

Tools You'll Need:

- Multimeter: A digital multimeter (DMM) capable of measuring resistance (ohms) and voltage is essential.

- Socket Wrench: To remove and install the sensor. Make sure you have the correct size socket.

- Oil Pressure Test Kit (Optional but Recommended): This will allow you to verify the oil pressure independently of the sensor.

- Wiring Diagram (Optional): A wiring diagram for your specific vehicle can be helpful, but generally, the 1-wire sensor will have a single wire connection.

- Safety Glasses and Gloves: To protect yourself from oil and potential hazards.

Steps:

- Safety First! Disconnect the negative battery cable to prevent any electrical shorts during the testing process.

- Locate the Oil Pressure Sensor: The oil pressure sensor is usually located on the engine block, near the oil filter. Consult your vehicle's repair manual or online resources for the exact location.

- Disconnect the Wire: Carefully disconnect the wire from the sensor. It is typically a single wire with a push-on connector.

- Remove the Sensor (Optional for Initial Test): You can perform an initial test without removing the sensor. However, removing it allows for a more thorough inspection and testing. Use the appropriate socket wrench to unscrew the sensor from the engine block. Be prepared for a small amount of oil to spill out.

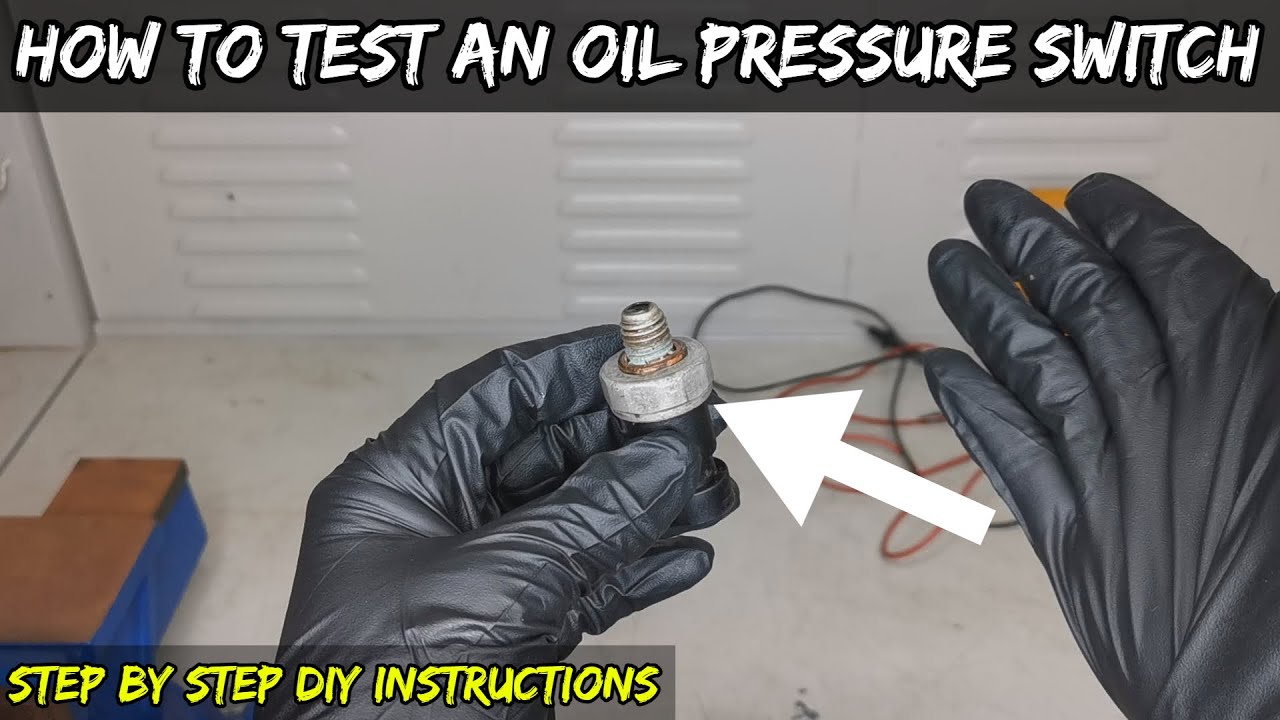

- Inspect the Sensor: Visually inspect the sensor for any signs of damage, such as cracks, corrosion, or oil leaks.

- Resistance Test (Sensor Removed):

- Set your multimeter to the ohms (Ω) setting.

- Connect one lead of the multimeter to the terminal on the sensor.

- Connect the other lead of the multimeter to the sensor's housing (the metal body).

- Blow into the sensor's pressure port, or use compressed air at a very low pressure. Observe the resistance reading on the multimeter. The resistance should change as you apply pressure. If the resistance remains constant or reads infinity (open circuit), the sensor is likely faulty.

- Resistance Test (Sensor Installed):

- Set your multimeter to the ohms (Ω) setting.

- Connect one lead of the multimeter to the wire that connects to the sensor.

- Connect the other lead to a good ground on the engine block.

- Start the engine. Observe the resistance reading on the multimeter. As the engine warms up and oil pressure increases, the resistance should decrease. If the resistance remains constant or doesn't change predictably with engine speed, the sensor may be faulty.

- Voltage Test (Engine Running):

- Set your multimeter to the DC voltage (VDC) setting.

- Reconnect the wire to the sensor.

- Connect the positive lead of the multimeter to the wire at the sensor.

- Connect the negative lead of the multimeter to a good ground on the engine block.

- Start the engine. The voltage reading should increase as the engine speed (and therefore oil pressure) increases. The exact voltage range will vary depending on the vehicle, so consult your vehicle's repair manual.

- Verify Oil Pressure with a Mechanical Gauge (Recommended): This is the most accurate way to confirm whether the sensor is providing accurate readings.

- Remove the oil pressure sensor.

- Install the oil pressure test kit in the sensor's location.

- Start the engine and compare the reading on the mechanical gauge with the reading on your dashboard gauge (or what you observed during the voltage test). If there's a significant discrepancy, the sensor is likely faulty.

- Reinstallation: If the sensor tests good and you removed it, reinstall it. Use Teflon tape on the threads to prevent leaks. Tighten the sensor to the manufacturer's specified torque. Reconnect the wire.

- Reconnect Battery: Reconnect the negative battery cable.

- Test Drive: Take the vehicle for a short test drive and observe the oil pressure gauge to ensure it's functioning correctly.

How to Choose the Right Replacement Oil Pressure Sensor

If your oil pressure sensor is faulty and needs replacing, it's important to choose the right replacement to ensure proper function and compatibility. Here are some factors to consider:

- Vehicle Compatibility: The most crucial factor is to choose a sensor that is specifically designed for your vehicle's make, model, and year. Check the part number in your vehicle's repair manual or use online parts catalogs to identify the correct sensor.

- Sensor Type: Ensure the replacement sensor is a 1-wire sensor, matching the original configuration.

- Brand Reputation: Opt for reputable brands known for producing quality automotive parts. While aftermarket options can be cheaper, they may not offer the same level of reliability and accuracy as OEM (Original Equipment Manufacturer) or reputable aftermarket brands.

- Pressure Range: Verify that the replacement sensor's pressure range matches the specifications of your vehicle's oil pressure system.

- Warranty: Choose a sensor that comes with a warranty. This provides protection against defects and ensures that you can get a replacement if the sensor fails prematurely.

Real-World Owner Experiences

Many vehicle owners have shared their experiences with faulty oil pressure sensors online. Here are some common themes:

- Erratic Gauge Readings: Owners often report experiencing fluctuating or unstable oil pressure gauge readings, even when the engine is running smoothly.

- False Alarms: The oil pressure warning light illuminating for no apparent reason is a frequent complaint. This can be particularly frustrating and lead to unnecessary trips to the mechanic.

- Engine Damage Due to Misdiagnosis: Some owners have unfortunately experienced engine damage due to misdiagnosing a faulty sensor as a genuine low oil pressure issue. In such cases, it is important to perform a mechanical test to confirm the actual oil pressure.

- Easy DIY Repair: Many owners have successfully replaced their oil pressure sensors themselves, saving on labor costs. However, it's crucial to follow the correct procedures and consult a repair manual if needed.

These experiences highlight the importance of accurate diagnosis and prompt action when dealing with oil pressure sensor issues.

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace an oil pressure sensor?

A: The cost can vary depending on the vehicle and the brand of the sensor. Generally, the sensor itself costs between $20 and $100. Labor costs can range from $50 to $150, depending on the mechanic's hourly rate and the complexity of the job. Doing it yourself can save on labor costs.

Q: Can I drive with a faulty oil pressure sensor?

A: It's not recommended. A faulty sensor can provide inaccurate readings, potentially masking a genuine low oil pressure situation. Continuing to drive with low oil pressure can cause severe engine damage. If you suspect a faulty sensor, have it tested and replaced as soon as possible.

Q: How often should I replace my oil pressure sensor?

A: There's no set replacement interval for oil pressure sensors. However, it's a good idea to inspect the sensor periodically for any signs of damage or corrosion. If you experience any of the symptoms mentioned above, such as erratic gauge readings or false warning lights, have the sensor tested immediately.

Q: What does an oil pressure sensor do?

A: An oil pressure sensor measures the oil pressure within your engine and sends this information to the vehicle's computer or dashboard gauge. This allows you to monitor the oil pressure and ensure that the engine is receiving adequate lubrication.

Q: Can a bad oil filter cause a low oil pressure reading?

A: Yes, a clogged oil filter can restrict oil flow and cause a drop in oil pressure. If you suspect a low oil pressure issue, it's a good idea to check and replace the oil filter as part of the diagnostic process.

By following these steps and understanding the importance of a functioning oil pressure sensor, you can proactively maintain your engine's health and avoid costly repairs.