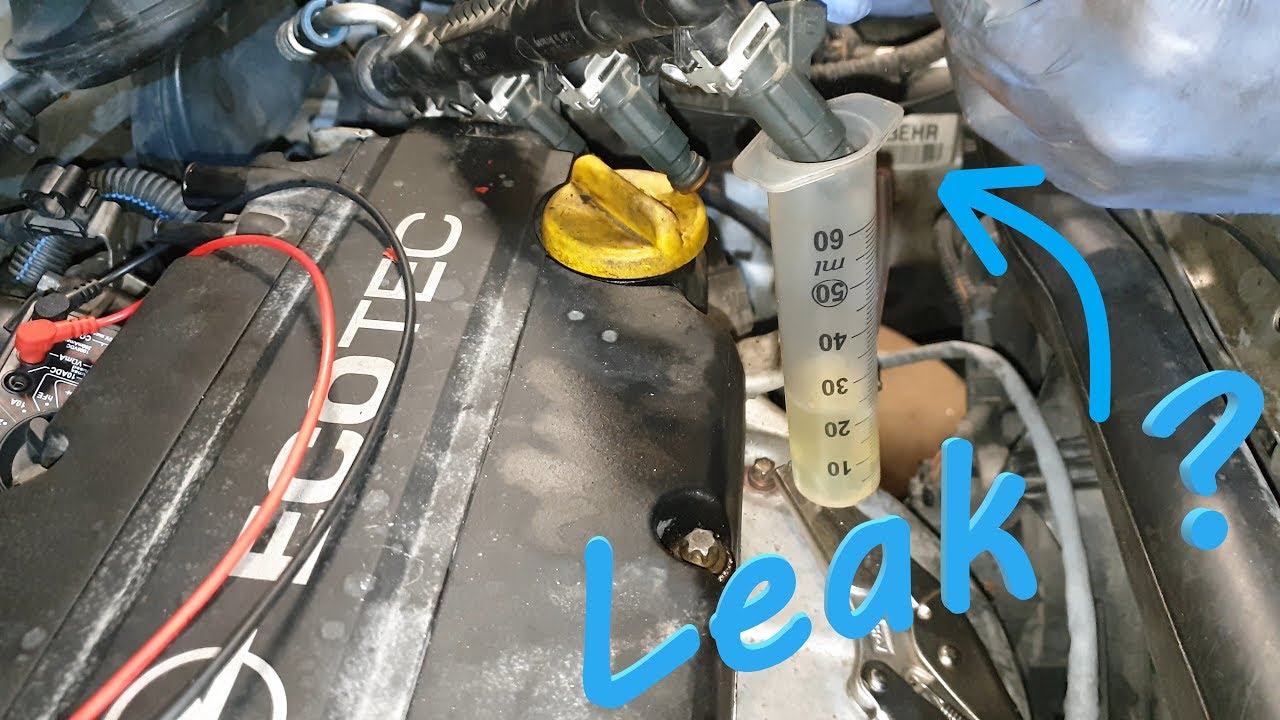

How To Test For Leaking Fuel Injector

Diagnosing a leaky fuel injector can save you headaches down the road, preventing potential engine damage, poor performance, and wasted fuel. This article provides a detailed guide for experienced DIYers and mechanics on how to properly test for leaking fuel injectors, ensuring accurate diagnosis and effective repairs.

Understanding Fuel Injection Systems

Before diving into testing, it's essential to understand the basics of fuel injection. Modern gasoline engines primarily use electronic fuel injection (EFI) systems. These systems replace carburetors with electronically controlled fuel injectors that spray atomized fuel directly into the engine's intake manifold or, in the case of direct injection, directly into the combustion chamber. The engine control unit (ECU), often referred to as the engine's "brain," precisely controls the pulse width (duration) of the injector opening based on various sensor inputs such as manifold absolute pressure (MAP), throttle position, engine speed (RPM), and oxygen sensor readings. This precise control results in improved fuel efficiency, reduced emissions, and enhanced engine performance.

Types of Fuel Injection:

- Throttle Body Injection (TBI): An older system, less common now, where injectors are located in the throttle body, spraying fuel into the incoming air stream.

- Multi-Port Fuel Injection (MPFI): Each cylinder has its own injector located in the intake manifold, near the intake valve. This provides more precise fuel delivery compared to TBI.

- Sequential Fuel Injection: A more advanced MPFI system where injectors are fired in sequence with the engine's firing order, further optimizing fuel delivery.

- Direct Injection (GDI): Injectors are mounted directly into the cylinder, allowing for very precise fuel delivery and higher compression ratios, leading to increased power and efficiency. GDI systems operate at much higher fuel pressures than port fuel injection.

How Fuel Injectors Work

A fuel injector is essentially a sophisticated solenoid valve. When the ECU commands fuel injection, it sends an electrical signal to the injector. This signal energizes a solenoid coil, which lifts a needle valve off its seat, allowing fuel to spray through a precision-engineered nozzle. The shape and size of the nozzle are critical for proper fuel atomization. Atomization is the process of breaking down the fuel into tiny droplets, which is crucial for efficient combustion. When the electrical signal is removed, the solenoid de-energizes, and a spring forces the needle valve back onto its seat, stopping the fuel flow.

The fuel itself is supplied to the injectors via a fuel rail, which is a metal tube that distributes fuel to all the injectors. Fuel pressure is maintained by a fuel pump, typically located in the fuel tank, and regulated by a fuel pressure regulator. This regulator ensures a consistent fuel pressure at the injectors, compensating for changes in engine load and vacuum.

Identifying a Leaking Fuel Injector

A leaking fuel injector can manifest in several ways. Recognizing these symptoms early can prevent more serious problems:

- Rough Idle: A leaking injector can cause an overly rich mixture in one or more cylinders, leading to an unstable and rough idle.

- Poor Fuel Economy: Excess fuel being delivered to the engine results in decreased miles per gallon (MPG).

- Hard Starting: When the engine is cold, a leaking injector can flood the cylinder(s), making it difficult to start. This is especially noticeable after the car has been sitting for a while.

- Fuel Smell: A strong fuel odor, especially near the engine, can indicate a fuel leak from an injector.

- Black Smoke from Exhaust: Excessive fuel in the combustion chamber can lead to incomplete combustion, resulting in black smoke from the exhaust.

- Engine Misfires: An overly rich mixture can cause misfires, triggering the check engine light and storing misfire codes (e.g., P0300, P0301, P0302) in the ECU.

- Wet Spark Plug: Inspecting the spark plugs can reveal a wet, fuel-fouled plug in the cylinder with the leaking injector.

- Hydrocarbon (HC) Levels: A smog test will reveal high levels of unburned hydrocarbons in the exhaust.

Testing Procedures: A Step-by-Step Guide

Here are several methods you can use to test for leaking fuel injectors:

1. The Visual Inspection:

This is the simplest and often the first step. Examine the fuel rail and injectors for any signs of fuel leakage. Look for dampness, fuel stains, or a strong fuel odor. Pay close attention to the injector seals (O-rings) where the injector connects to the fuel rail and the intake manifold. A small leak can evaporate quickly, so a bright light and a careful inspection are essential.

2. The Fuel Rail Pressure Test:

This test requires a fuel pressure gauge. Connect the gauge to the Schrader valve on the fuel rail (if equipped). Start the engine and allow it to idle. Note the fuel pressure. Then, turn off the engine and observe the fuel pressure gauge. The pressure should hold steady for at least 15-20 minutes. A rapid pressure drop indicates a leak in the fuel system, which could be a leaking injector, a faulty fuel pressure regulator, or a leak in the fuel lines. To isolate the injectors, you can perform a leak-down test. After shutting off the engine, clamp off the fuel supply line (use a specialized fuel line clamp to avoid damage). If the pressure still drops, the leak is likely at an injector or within the fuel rail itself.

3. The "Stethoscope" Test:

Using a mechanic's stethoscope, listen to each injector while the engine is running. You should hear a distinct clicking sound as the injector opens and closes. A silent injector indicates a potential electrical problem or a completely blocked injector, while an injector that sounds different from the others (e.g., hissing or sputtering) may be leaking.

4. The Cylinder Balance Test (Power Balance Test):

This test involves temporarily disabling each injector, one at a time, while the engine is running. This can be done by disconnecting the electrical connector to the injector. As each injector is disabled, listen to the engine's RPM. If the engine RPM drops significantly when an injector is disabled, it indicates that the cylinder was contributing to the engine's overall power output, suggesting the injector is functioning correctly. However, if disabling an injector has little or no effect on engine RPM, it suggests that the cylinder was not contributing much power, which could be due to a leaking injector flooding the cylinder. This test is best performed using a scan tool that can monitor RPM and cylinder contribution.

5. The Injector Resistance Test:

Using a multimeter, measure the resistance of each injector. The resistance value varies depending on the injector type, but generally, most injectors have a resistance between 10 and 18 ohms. Refer to the vehicle's service manual for the correct resistance specification. A significantly higher or lower resistance value indicates a faulty injector. Note: This test only indicates an electrical fault within the injector solenoid and does not directly test for leakage.

6. The "Paper Towel" Test (Less Precise, but Simple):

With the engine cold, place a clean paper towel under each injector. Start the engine briefly, then immediately shut it off. Examine the paper towels. If any towel is wet with fuel, it indicates a leaking injector. This test is less precise than others, but can be a quick preliminary check.

7. Professional Injector Cleaning and Flow Testing:

The most accurate way to test for leaking injectors is to remove them and send them to a professional injector cleaning and flow testing service. These services use specialized equipment to clean the injectors, test their spray pattern, measure their flow rate, and check for leaks. This service can also identify partially clogged injectors, which can also cause performance problems.

Do’s and Don’ts / Best Practices

- Do use proper safety precautions. Gasoline is highly flammable. Work in a well-ventilated area and avoid sparks or open flames. Wear safety glasses and gloves.

- Do disconnect the negative battery cable before working on the fuel system to prevent accidental electrical shorts.

- Do refer to the vehicle's service manual for specific instructions and torque specifications.

- Do use new O-rings when reinstalling fuel injectors.

- Don't smoke or use open flames near the fuel system.

- Don't use excessive force when removing or installing injectors. They are delicate and can be easily damaged.

- Don't reuse old O-rings. They can leak.

- Don't ignore a suspected fuel leak. Fuel leaks can lead to serious engine damage and fire hazards.

- Best Practice: After replacing injectors, perform a fuel trim reset using a scan tool to allow the ECU to relearn the new injector characteristics.

- Best Practice: If replacing one injector, consider replacing all injectors, especially if the vehicle has high mileage. This ensures consistent fuel delivery across all cylinders.

Common Issues and Maintenance Concerns

Fuel injectors are susceptible to clogging due to contaminants in the fuel. Regular use of fuel injector cleaners can help prevent clogging and maintain optimal performance. However, excessive use of fuel injector cleaners can also damage some injector types, so follow the manufacturer's recommendations.

Injector O-rings can dry out and crack over time, leading to fuel leaks. Replacing the O-rings during routine maintenance can prevent these leaks. Also, ensure the fuel filter is replaced regularly to prevent contaminants from reaching the injectors.

Conclusion

Testing for a leaking fuel injector requires a systematic approach and a basic understanding of fuel injection systems. By following the steps outlined in this article, you can accurately diagnose a leaking injector and take the necessary steps to repair or replace it. Remember to prioritize safety and consult the vehicle's service manual for specific instructions. If you're not comfortable performing these tests yourself, it's always best to consult a qualified mechanic. Catching a fuel injector leak early can prevent more costly engine repairs and ensure your vehicle runs smoothly and efficiently. Ultimately, proper diagnosis and timely repair of a fuel injector leak is an investment in the longevity and performance of your vehicle.